A number of technologies are used to manufacture prototypes. Plastic prototypes are often machined from ABS, polystyrene, or rigid polyurethane foam.

An alternate method of manufacturing prototypes is to cast a liquid thermosetting resin into a mold, where it then hardens to form a finished part.

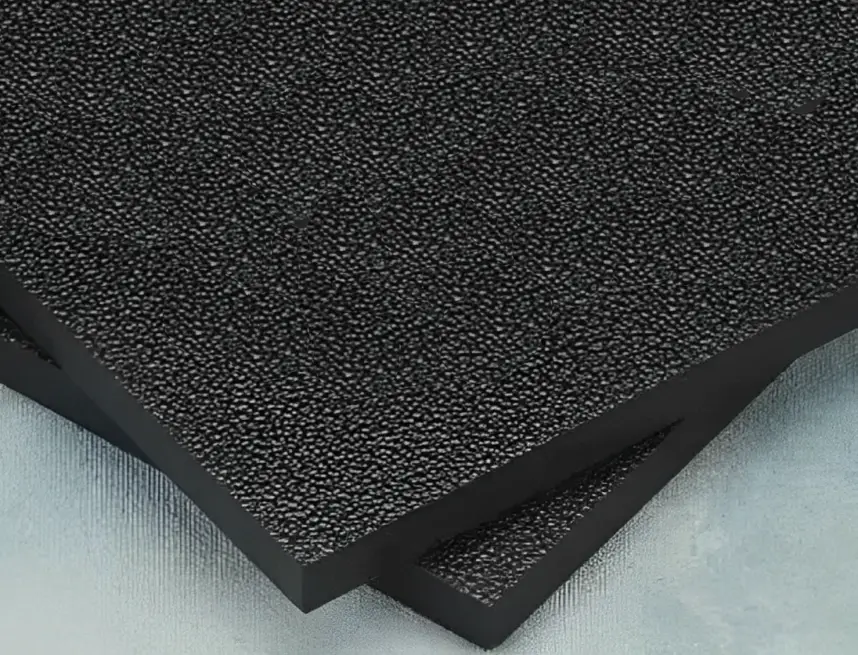

ABS

Outstanding impact resistant low cost plastic, easy to machine, and thermoform.

Acetal

High strength, stiff, low friction engineering plastic with good wear properties.

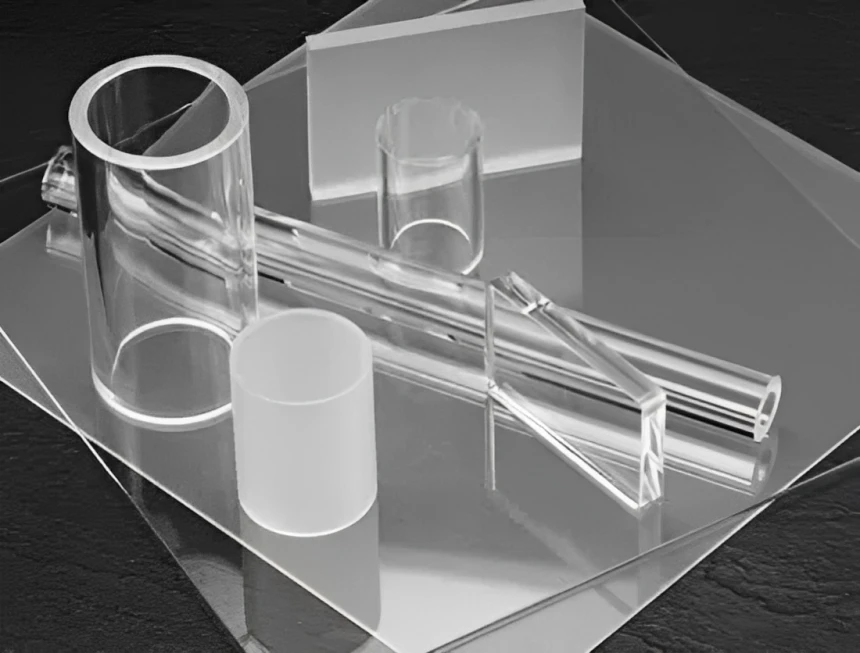

Acrylic

Outstanding strong, stiff, clear plastic available in a variety of brilliant colors and finishes.

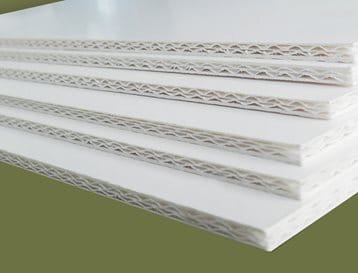

Foam Boards

Rigid, yet lightweight, family of graphic art boards, easy to fabricate and cost effective.

High Impact Polystyrene

Low cost, tough plastic material that is easy to thermoform and fabricate.

Nylon

Paper Boards

100% recyclable board material for interior sign and display short term applications.

Polycarbonate

Polycarbonate Film

Transparent, general purpose plastic film with excellent ink adhesion.

PVC

Strong, stiff, versatile low cost plastic material that is easy to fabricate, bond, and weld.