PPH Dual Block 3 Way Ball Valve

PPH Dual Block 3 Way Ball Value

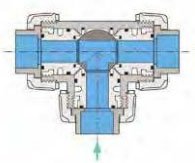

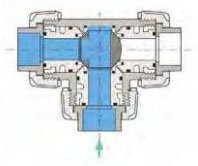

In most cases, the PPH Dual Block 3 Way Ball Valve has two modes of operation: input and output. A three-way ball valve may be recommended in some systems when more than one medium is used. Instead of just two ports (entries), 3-way ball valves have three.

This multiport arrangement can divert fluid from the primary valve input in two different directions (instead of just one) via two independent valve outputs. The primary flow line is served by two separate and alternate inlets, which is another common application of the PPH Dual Block 3 Way Ball Valve.

Flow pattern, handle direction, and the range of 90-degree spin that the handle can make are all used to classify three-way ball valves. Because of how the valve ball is drilled and the pipe design, gas and liquid flow can be diverted, mixed, blocked, or completely stopped in one direction. By reducing the need for an additional tee and valve, multiport valves save space.

PPH Valves

PPH Valves

Get Quick Information

PETRONTHERMOPLAST has developed a TKD DUAL BLOCK® ball valve to introduce a high reference standard in thermosplastic valve design. TKD is a True Union diverting and mixing ball valve that meets the most stringent needs required in industrial applications.

• Connection system for solvent weld, threaded and flanged joints

• Patented SEAT STOP® ball carrier system that lets you micro-adjust ball seats and minimise axial force effects

• Easy radial dismounting allowing quick replacement of O-rings and ball seats without any need for tools

• PN16 True Union valve body made for rigid PVC-U injection moulding

equipped with built-in bores for actuation. ISO 9393 compliant test requi-sites

• Option of dismounting downstream pipes with the valve in the closed position

• High surface finish stem with double O-Ring and double connection key to the ball, equipped with visual ball position indicator for correct handle

installation

• Integrated bracket for valve anchoring

• Possibility of installing pneumatic and/or electric actuators thanks to the robust anchor tower for easy and quick automation using the Power Quick module (optional)

• Possibility to have handle with integrated LSQT limit micro switch, even as a retrofit in existing installations

| Technical specifications | |

|---|---|

| Construction | 3-way True Union ball valve with locked carrier and union nuts |

| Size range | DN 10 ÷ 50 |

| Nominal pressure | PN 16 with water at 20 °C |

| Temperature range | 0 °C ÷ 60 °C |

| Coupling standards | Solvent welding: EN ISO 1452, EN ISO 15493, BS 4346-1, DIN 8063, NF T54-028, ASTM D 2467, JIS K 6743. Pipe coupling capacity according to EN ISO 1452, EN ISO 15493, DIN 8062, NF T54-016, ASTM D 1785, JIS K 6741 Thread: ISO 228-1, DIN 2999, ASTM D 2467 JIS B 0203. |

| Reference standards | Construction criteria: EN ISO 16135, EN ISO 1452, EN ISO 15493 Test methods and requirements: ISO 9393 Installation criteria: DVS 2204, DVS 2221, UNI 11242 Actuator couplings: ISO 5211 |

| Valve material | PVC-U |

| Seal material | EPDM, FKM (standard size O-Ring); PTFE (ball seats) |

| Control options | Manual control; electric actuator; pneumatic actuator |

Dual Block 3-Way Ball Valve

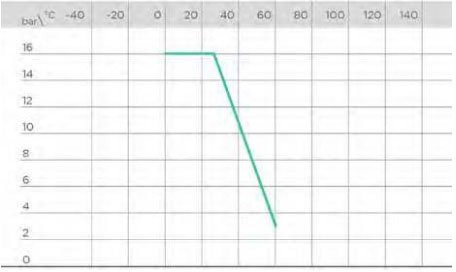

PRESSURE VARIATION ACCORDING TO TEMPERATURE

For water and harmless fluids to which the material is classified as CHEMICALLY RESISTANT. In other cases, a reduction of the nominal PN pressure is required (25 years with safety factor).

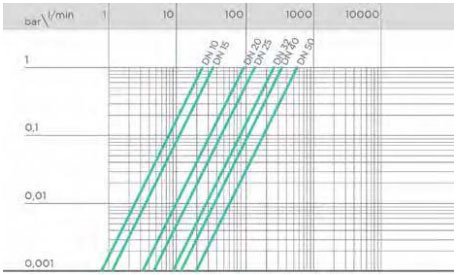

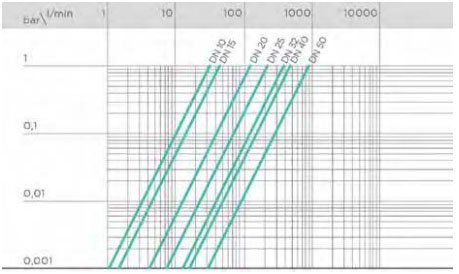

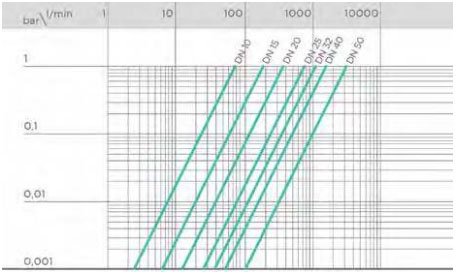

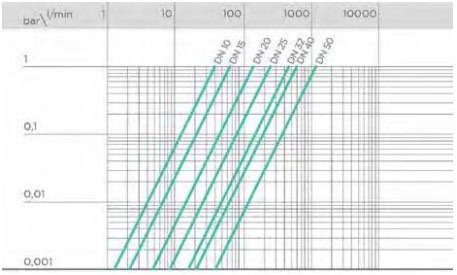

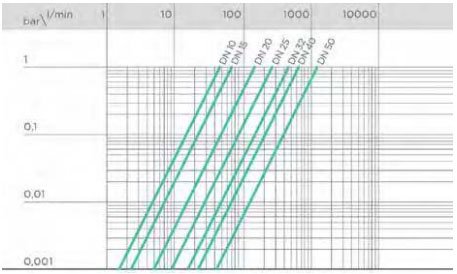

PRESSURE DROP GRAPH AND WORK POSITIONS

A – T-port ball valve:

0°- Mixing

A – T-port ball valve:

0°- Mixing

B – T-port ball valve:

90° – Diverting

D – T-port ball valve:

270° – Diverting

E – L-port ball valve:

0°/270° – Diverting

KV 100 FLOW COEFFICIENT

The Kv 100 flow coefficient is the Q flow rate of litres per minute of water at a temperature of 20°C that will generate Δp= 1 bar pressure drop at a certain valve position. The Kv100 values shown in the table are calculated with the valve completely open.

| DN | 10 | 15 | 20 | 25 | 32 | 40 | 50 |

|---|---|---|---|---|---|---|---|

| A | 25 | 35 | 95 | 140 | 270 | 330 | 620 |

| B | 37 | 55 | 135 | 205 | 390 | 475 | 900 |

| C | 78 | 195 | 380 | 760 | 1050 | 1700 | 3200 |

| D | 40 | 65 | 145 | 245 | 460 | 600 | 1200 |

| E | 48 | 73 | 150 | 265 | 475 | 620 | 1220 |

OPERATING TORQUE AT MAXIMUM WORKING PRESSURE

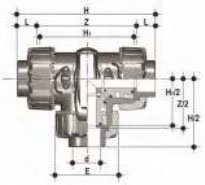

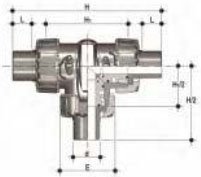

Dimensions shared by all versions

Dimensions shared by all versions| d | DN | B | B1 | C | C1 |

|---|---|---|---|---|---|

| 16 | 10 | 54 | 29 | 67 | 40 |

| 20 | 15 | 54 | 29 | 67 | 40 |

| 25 | 20 | 65 | 34,5 | 85 | 49 |

| 32 | 25 | 69,5 | 39 | 85 | 49 |

| 40 | 32 | 82,5 | 46 | 108 | 64 |

| 50 | 40 | 89 | 52 | 108 | 64 |

| 63 | 50 | 108 | 62 | 134 | 76 |

TKDIV

DUAL BLOCK® 3-way ball valve with metric plain socket ends for solvent welding, T bore.| d | DN | PN | E | H | H1 | L | Z | g | EPDM code | FKM code |

|---|---|---|---|---|---|---|---|---|---|---|

| 16 | 10 | 16 | 54 | 118 | 80 | 14 | 90 | 310 | TKDIV016E | TKDIV016F |

| 20 | 15 | 16 | 54 | 118 | 80 | 16 | 86 | 310 | TKDIV020E | TKDIV020F |

| 25 | 20 | 16 | 65 | 145 | 100 | 19 | 107 | 550 | TKDIV025E | TKDIV025F |

| 32 | 25 | 16 | 73 | 160 | 110 | 22 | 116 | 790 | TKDIV032E | TKDIV032F |

| 40 | 32 | 16 | 86 | 188.5 | 131 | 26 | 136.5 | 1275 | TKDIV040E | TKDIV040F |

| 50 | 40 | 16 | 98 | 219 | 148 | 31 | 157 | 1660 | TKDIV050E | TKDIV050F |

| 63 | 50 | 16 | 122 | 266.5 | 179 | 38 | 190.5 | 2800 | TKDIV063E | TKDIV063F |

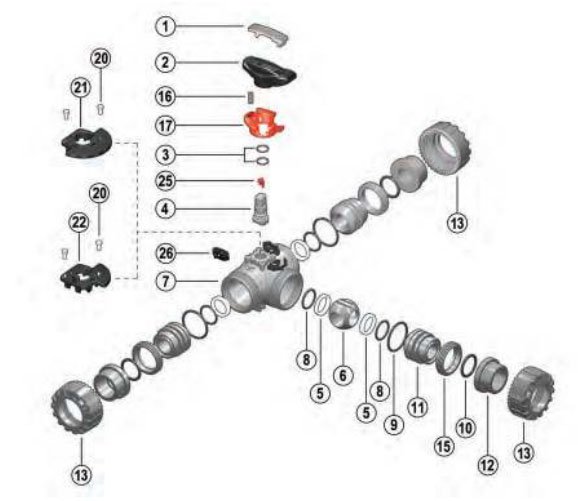

- 1 Handle insert (PVC-U – 1)

- 2 Handle (HIPVC – 1)

- 3 Stem O-ring (EPDM-FKM – 2)*

- 4 Stem (PVC-U – 1)

- 5 Ball seat (PTFE – 4)*

- 6 Ball (PVC-U – 1)

- 7 Body (PVC-U – 1)

- 8 Ball seat O-Rings (EPDM-FKM- 4)*

- 9 Radial seal O-Ring (EPDM-FKM- 3)

- 10 Socket seal O-Ring (EPDM-FKM- 3)*

- 11 Ball seat carrier (PVC-U – 3)

- 12 End connector (PVC-U – 3)*

- 13 Union nut (PVC-U – 3)

- 15 Threaded ring (PVC-U – 3)

- 16 Spring – SHKD accessory (STAINLESS steel – 1)**

- 17 Safety handle block – SHKD accessory (PP-GR – 1)**

- 20 Rivet for LTKD (POM – 2)**

- 21 LTKD 180° (POM – 1)**

- 22 LTKD 90° (POM – 1)**

- 25 Position indicator (POM – 1)

- 26 DUAL BLOCK® (POM – 3)

* Spare parts

** Accessories

The component material and quantity supplied are indicated in the parentheses.

GET THE LATEST PPH Dual Block 3 Way Ball Valve PRICES ON YOUR EMAIL