PAI MATERIALS

PAI (polyamide-imide) is a resin that is exceptionally strong and stiff. It’s frequently utilised in high-temperature settings where other thermoplastics’ mechanical qualities would be compromised. PAI is a dimensionally stable material with a low coefficient of thermal expansion (CTE), making it a good choice for applications requiring close precision machining. It comes in a number of different formulations.

PAI is known across the globe as the highest performing melt-processable thermoplastic material. PAI keeps its strength and rigidity at temperatures up to 500 degrees Fahrenheit (260 degrees Celsius). Its maximum growth rate is 500 degrees Fahrenheit (260 degrees Celsius). In bearing grades, PAI Manufacturer in India that offers good wear resistance.

PAI IS WIDELY USED FOR:

- Semiconductor machinery parts

- Chip test sockets

- Aerospace components

- Electrical connectors

- Bearings and bushings

- Bearing cages

- Pump and valve parts

- Seals

PERFORMANCE CHARACTERISTICS:

- Strong and stiff

- Performs well at elevated temperatures

- Extremely low thermal expansion

- Excellent electrical insulating properties (electrical grade)

- Outstanding bearing and wear properties (bearing grade)

- Good resistance to many common solvents, fuels, and acids

COMMON BRANDS:

- Tecator

- Torlon® PAI

- Duratron® PAI

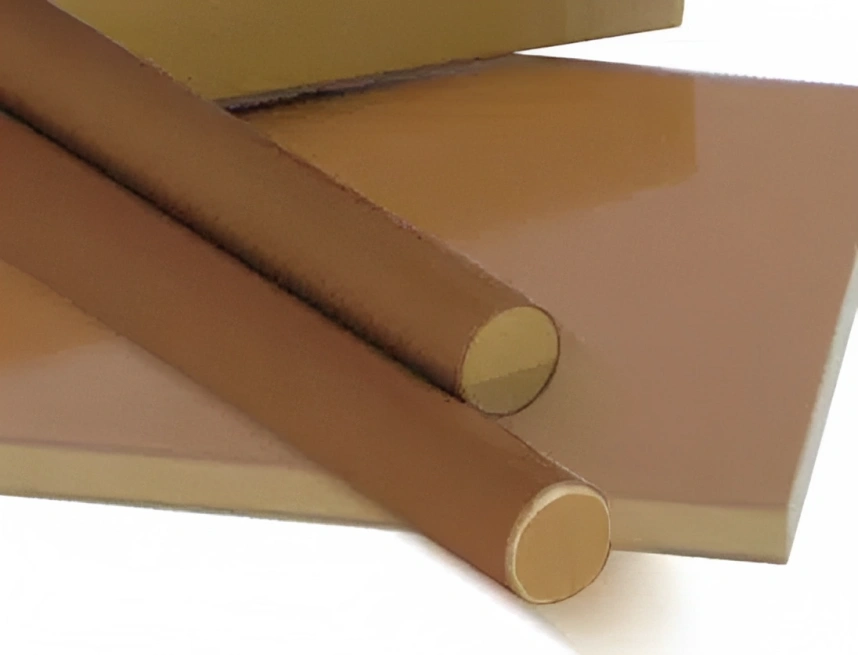

STANDARD SIZES

| SHEET | Dimensions: 12 in x 48 in |

| Thickness: 0.250 in – 1 in |

| ROD | Outside Diameter: 0.394 in – 3.940 in |

| ROD | Outside Diameter: 0.250 in – 14 in |

OPTIONS AVAILABLE

| COLOR | Natural |

| GRADES | Bearing, Electrical |

Length, width, thickness, and diameter tolerances vary by size, by manufacturer, brand, and grade. Custom sizes available upon request.

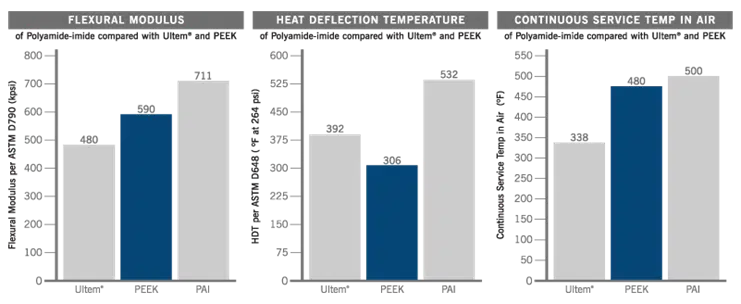

PAI Properties and Material Options

Unfilled/Electrical Grade PAI– has extremely high dielectric strength and it is often used for applications where it functions as an electrical insulator.

Bearing Grade PAI– can be used for demanding bearing applications that require extreme loads, speeds, and/or elevated temperatures.

TYPICAL PROPERTIES OF HDPE

| UNITS | ASTM TEST | PAI UNFILLED GRADE | PAI BEARING GRADE | |

|---|---|---|---|---|

| Tensile strength | psi | D638 | 20,000 | 15,000 |

| Flexural modulus | psi | D790 | 600,000 | 800,000 |

| Izod impact (notched) | ft-lbs/in of notch | D256 | 2.0 | 0.8 |

| Heat deflection temperature @ 264 psi | °F | D648 | 532 | 534 |

| Water absorption (immersion 24 hours) | % | D570 | 0.4 | 0.28 |

| Coefficient of linear thermal expansion | in/in/°Fx10-5 | D696 | 1.7 | 1.4 |

Note: The properties reported reflect typical values for extruded PAI shapes. The properties of compression molded and injection molded PAI will vary from these values.

Please ask your Petron Thermoplast representative for more specific information about an individual brand.

Explore the physical, mechanical, thermal, electrical, and optical properties of PAI.

Sort, compare, and find the plastic material suited for your application using our interactive properties table.