- ABS Rod

- Acetal Rod

- Acrylic (Perspex) Rod

- Nylon 6 Rod

- Nylon 66 Rod

- Nylon 12 Rod

- PEEK Rod

- PEI (Ultem) Rod

- PET Rod

- PET (Ertalyte) Rod

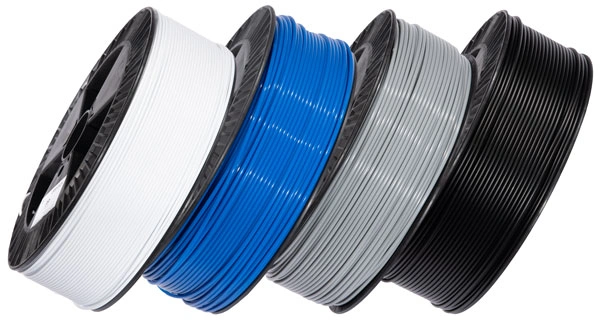

- Plastic Welding Rod

- Polycarbonate Rod

- PE300 Rod - HDPE

- PE1000 Rod - UHMW

- Polypropylene Rod

- PSU (Polysulfone) Rod

- PTFE Rod

- PVC Rod

- PVDF Rod

- Vespel Rod

- Metal Detectable Plastic Rod

Description

Petron Thermoplast has been manufacturing and providing semi-finished polymers to industry for over years as a reliable provider of plastic rods. We sell a wide selection of thermoplastics used in various industries and are frequently used in demanding applications as a replacement for conventional materials like metal.

At Petron Thermoplast, we have a huge inventory of machining, display, and speciality grades in various diameters and lengths. Acetal copolymer, which has high stiffness and wears resistance, PVC, strong chemical resistance and outstanding electrical insulating qualities, and polypropylene, which is acid-resistant and lightweight, are popular choices.

Standard engineering grades for general purpose machining, cast moly filled for high load-bearing applications, cast oil-filled for increased wear resistance and lower coefficient of friction are also available.

Alternatively, we provide a variety of polymers such as acrylic, nylon 12, and polycarbonate if great optical clarity is required for display applications. Engineered grades for usage in harsh industrial settings are also available, and polymers like PEEK stand up to strong chemicals, hydrolysis, high temperatures, and wear particularly well.

Explore the website for additional information on different grades of plastic rods, including availability and technical data. If you’re not sure which engineering plastic grade you need for your application, a PDF comparison table and chemical resistance summary may be found at the bottom of this page. Alternatively, you may get in touch with our technical sales team, who would be pleased to help.

Machining, Display & Specialist Plastic Rod

Plastic Rod

ABS Rod

Offering great scratch resistance, strong impact strength, and outstanding dimensional stability. ABS rod is a robust, rigid polymer that may be easily machined into components for application in a variety of industries. Natural is offered in a variety of lengths and diameters. range of temperatures up to +75 °C.

Acetal Rod

Available in a range of grades, including metal-detectable, copolymer, and homopolymer. Acetal is a robust, rigid material with great wear and impact resistance, high mechanical strength, and low moisture absorption. It is frequently transformed into components for use in the food industry or parts like gears or friction bearings.

Acrylic (Perspex®) Rod

Due to the transparency of the polymer, acrylic rod has strong UV resistance, outstanding optical clarity, and is frequently utilised in display applications. It can be shaped, polished, and machined to create eyeglasses, lighting feature components, and display parts. range of temperatures up to +70°C.

Metal Detectable Plastic Rod

High wear resistance, a low coefficient of friction, and exceptional chemical resistance are among the features that may be found in a variety of polymers. Metal detectable rod is frequently used in food processing applications and aids in preventing contamination.

Nylon 6 Rod

An engineering plastic that is frequently used for a variety of purposes is nylon 6. It has good mechanical qualities, a high tensile strength, and mild chemical resistance. Wheels, bearings, gears, and rollers are all made of nylon 6. Both cast and extruded forms are offered.

Nylon 66 Rod

Offering excellent electrical insulation qualities, low moisture absorption, and great mechanical strength. Compared to other polyamides, nylon 66 offers better resistance to creep, stiffness, and wear. It comes in a variety of grades, including glass-filled and

Nylon 12 Rod

A transparent polyamide with good mechanical strength and mediocre abrasion resistance. Compared to the extruded grades of nylon 6 and 66, nylon 12 has improved chemical resistance and absorbs less moisture. It is frequently made into eye glasses, pump components, and gear wheels. range of temperatures up to +80.

PEEK Rod

PEEK is a specialised plastic with superior mechanical qualities, high chemical and wear resistance, and excellent dimensional stability. It is frequently machined into wafer supports, vacuum seals, and piston parts for use in demanding applications. -60°C to +250°C in the temperature range.

PEI (Ultem®) Rod

Providing great stiffness, superior electrical characteristics, and strong thermal stability. PEI is an FDA-approved amorphous polymer that can be used in applications involving hot steam sterilisation. It is frequently produced into electrical and medicinal components. range of temperatures up to 170 °C.

PET Rod

Providing great creep resistance, strong strength, and high dimensional stability. PET is a good electrical insulator, has a low moisture absorption rate, and works well in applications with heavy loads. It is natural, FDA-approved, and may be machined into a variety of components. -20°C to +115°C in the temperature range.

PET (Ertalyte®) Rod

Available in two classes, each of which offers a unique set of qualities. In addition to Ertalyte® TX, which has the additional feature of being self-lubricating, there is Ertalyte® PET-P, which has great mechanical strength and is perfect for machining. The FDA has authorised both choices. -20°C to 110°C in the temperature range.

Plastic Welding Rod

A variety of polymers, including PETG, polycarbonate, polyethylene, polypropylene, and PVC, are readily available. Both extrusion welders and hot air plastic welding guns can be used with plastic welding rod. It comes in a variety of colours and sizes and is used to thermally fuse two pieces of the same material together.

Polycarbonate Rod

A robust, impact-resistant polymer known as polycarbonate offers exceptional optical clarity, good ozone resistance, and mediocre tolerance to high temperatures. Mostly, it is machined into items like eyeglasses, light fixtures, bushings, and optical parts. -40°C to +115°C in the temperature range.

Polyethylene PE300 (HDPE) Rod

Having excellent electric and dielectric properties, a low coefficient of friction, and good wear resistance. An FDA-approved, lightweight polymer with low moisture absorption and strong chemical resistance is called PE300 (HDPE). temperature range of -50 to +80 degrees Celsius.

Polyethylene PE1000 (UHMW) Rod

UHMW offers exceptional resistance to abrasion, impact, and wear. It has outstanding dielectric characteristics and an extremely low coefficient of friction. FDA-approved, PE1000 (UHMWPE) can be manufactured into a variety of components. the range from -167°C to +90°C in temperature.

Polypropylene Rod

The lightweight material polypropylene has strong chemical resistance, outstanding electrical insulating qualities, and high tensile strength. Due of its resistance to acids, it is frequently produced into goods for use in the chemical industry. temperature range of -20 to +80 degrees Celsius.

PSU (Polysulfone) Rod

A high-performing, amorphous polymer with food approval, polysulfone rod has superior electrical, thermal, and mechanical properties. For frequent usage in steam sterilisation applications, it offers great dimensional stability. range of -100°C to +160°C in temperature.

PTFE Rod

PTFE is a high-performance polymer with a wide operating temperature range, a very low coefficient of friction, and great chemical resistance. Our selection comprises several grades with attributes like enhanced creep resistance or partial electrical conductivity.

PVC Rod

A stiff plastic with good chemical resistance, low moisture absorption, and great mechanical strength. PVC is simple to mill, bind, and weld, and it comes in a variety of colours. It is frequently made into electrical insulators, pump parts, valve bodies, and chemical apparatus. range of temperatures up to +60 °C.

PVDF Rod

Providing good electrical insulating qualities, dimensional stability, and exceptional mechanical strength. Outstanding resistance to UV rays, corrosion, and chemicals is provided by PVDF. It can be easily welded, is FDA-approved, and is frequently machined into anti-corrosion components. -30°C to +140°C in the temperature range.

Vespel® Rod

A variety of polyimides with high performance that offer good wear, impact, and creep resistance. Vespel® is utilised in applications that demand a durable plastic and are exposed to high temperatures. It is frequently made into seals, electrical insulators, valve seats, and bearings. range of temperatures up to +288°C.