Description

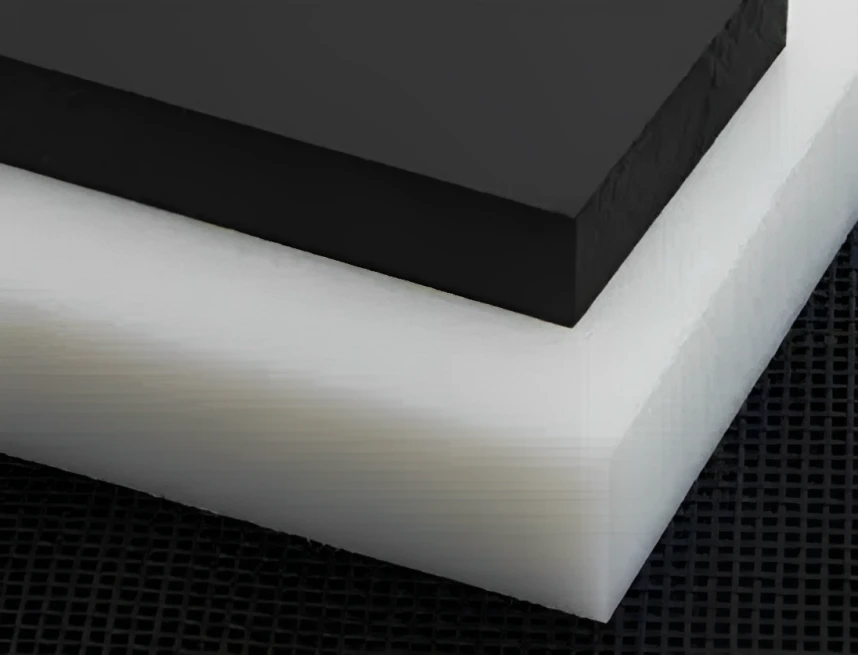

Plastic Materials For Welded Tanks, Benches, And Cabinets

Welding is an economical method for joining plastic sheets such as HDPE, PVC, PP, and PVDF.

Welded applications include chemical tanks, cabinets, and wet benches for the semiconductor industry.

Manufacturing methods include hot gas welding, extrusion welding, and butt welding. If using welding rod, make sure it is compatible with the polymer being joined. Some plastics have to be welded in a nitrogen atmosphere to prevent oxidation.

Easy to Weld

ECTFE

Fluoropolymer with outstanding mechanical properties and dimensional stability.

ETFE

Plastic material with excellent mechanical strength, stiffness, and abrasion resistance.

FEP

Flexible fluoropolymer with outstanding chemical resistance and electrical properties.

HDPE

LDPE

Soft, flexible, lightweight plastic material that is easy to fabricate and form.

PFA

Flexible fluoropolymer that performs well in extreme temperature and harsh chemical environments.

Polypropylene

Low cost, chemical resistant plastic with excellent aesthetic qualities.

PVC

Strong, stiff, versatile low cost plastic material that is easy to fabricate, bond, and weld.

PVDF

High purity engineering plastic with excellent chemical, abrasion, and flame resistance.