The Best ABS Plastic Pipes

ABS plastic pipes and fittings are commonly used for various domestic and commercial reasons, such as pipeline connections and different other things. Bisphenol A, or BPA, is a chemical that is often used to harden the plastic. It is available in a variety of plastic materials, including food and water containers. While there is no proof that BPA is harmful to people, animal studies have raised concerns about possible hormonal, neurological, and cardiovascular impacts, among other issues. In recent years, the administration has amended its BPA recommendations.

ABS Pipe Fittings

ABS Pipe Fittings

What Is PVC ABS Plastic Pipes

ABS plastic pipes and fittings are commonly used for various domestic and commercial reasons, such as pipeline connections and different other things. Bisphenol A, or BPA, is a chemical that is often used to harden the plastic. It is available in a variety of plastic materials, including food and water containers. While there is no proof that BPA is harmful to people, animal studies have raised concerns about possible hormonal, neurological, and cardiovascular impacts, among other issues. In recent years, the administration has amended its BPA recommendations.

ABS polymers have a long and illustrious history

ABS polymers are the fundamental components of pipe development. ABS plastic, also known as Acrylonitrile Butadiene Styrene (ABS), is an amorphous, impact-resistant, opaque thermoplastic commonly used in the plastics industry. The thermoplastic is composed out of three monomer units, as the name suggests:

• Acrylonitrile: An ammonia and propylene-based synthetic monomer.

• Butadiene is a monomer that is produced as a bi-product of steam crackers together with ethylene.

• Styrene is a monomer formed when ethylbenzene is dehydrogenated.

The thermoplastic has distinct characteristics due to each monomer unit. Acrylonitrile contributes to the material’s excellent chemical and heat resistance, butadiene gives strength and toughness, and Styrene adds rigidity and processability.

Advantages of ABS Pipe and Fittings

• ABS plastic pipes have numerous advantages, ranging from low production costs to a durable, aesthetically beautiful construction.

• Its capacity to survive many heating and cooling cycles makes it ideal for recycling.

• ABS has a wide range of color and surface texture possibilities and may be fabricated to a high-quality finish.

• Finally, ABS has a low heat and electricity conductivity, making it ideal for items that require electrical insulation. It also has good impact resistance and can effectively and consistently absorb shock.

ABS Pipes have the following properties

ABS plastic fittings are known for their structural strength. This makes it an excellent choice for various applications that require a robust and stiff plastic that can withstand external forces. It is widely utilized in applications that require structural stability, such as protective housings, camera housings, rigid packaging, and so on.

The fundamental physical features of ABS plastic are as follows:

• Excellent impact resistance

• Extreme stiffness

• Chemical and heat resistance

• Electrical insulating properties are excellent

• Resistance against abrasion and stains

• Structural and Dimensional Consistency

• Good brightness on the surface

The chemical characteristics of ABS thermoplastic are as follows:

• Excellent acid and alkali resistance (in diluted form)

• Aliphatic hydrocarbon resistance that is reasonable

• Glass transition temperature (liquefying temperature): 105 °C (221 °F)

• 204–238°C (400–460°F) injection molding temperature

• Alcohols, halogenated hydrocarbons, and aromatic hydrocarbons have little resistance.

The recyclable property is:Following analysis of the separated polymers, the recovered form of acrylonitrile butadiene styrene is ready to be combined with virgin ABS to create a new product. Water streams remove high purity plastics from a mixture of plastics in this technique. ABS Plastic Pipe & Fittings Manufacturer in India says recycling is an appealing economic option. ABS may be used with other materials to create high-quality, low-cost products.

ABS Pipe Fittings Technical Details

Material Properties

| Material Property | Unit | Value | |

| Ultimate tensile strength (strain rate 2 inches/min) | 73oF (22.79oC) 176oF (80oC) | lbf/in2 lbf/in2 | 5,500 3,150 |

| Modulus of elasticity | 73oF (22.79oC) 176oF (80oC) | lbf/in2 lbf/in2 | 240,000 185,000 |

| Izod impact strength notched | 73oF (22.79oC) | ft.lb/in notch | 8.5 |

| Specific gravity | – | 1.04 | |

Pipe Avability

| Pipe Class | Continuous Pressure Rating @ 73oF (23oC) | Size Range |

| Class 90 psi | 90 psi (6 bar) | 10“ and 12“ |

| Class 115 psi | 115 psi (8 bar) | 6“ and 8“ |

| Class 145 psi | 145 psi (10 bar) | 1“ to 8“ |

| Class 180 psi | 180 psi (12 bar) | 1“ to 6“ |

| Class 230 psi | 230 psi (16 bar) | 3/8“ to 4“ |

| Class T 230 psi | (16 bar) | 3/8“ to 2“ |

Valve Availability3

| Valve Type | Size Range |

| Ball Valve (VKD) | 3/8“ – 4“ |

| Ball Valve (VXE) | 1/2“ – 2“ |

| Ball Check Valve (SXE) | 1/2“ – 2“ |

| Diaphragm Valve (VM) | 1/2“ – 4“ |

| Butterfly (FK) | 2“ – 8“ |

| Strainers (RV) | 1/2“ – 2“ |

Fitting Availability

| Fitting | Size |

| Saddle Clips | 3/8“ – 4“ |

| Cobra Clips | 3/8“ – 4“ |

| Couplings | 3/8“ – 12“ |

| Flange, Full-Face – Undrilled/Socket | 1/2“ – 6“ |

| Flange, Full-face – Drilled ASA 150, Socket | 1/2“ – 6“ |

| Flange, Stub – Socket | 2“ – 12“ |

| Gaskets | 1/2“ – 12“ |

| Backing Rings – Galvanized Mild Steel, Drilled to ASA 150 | 1/2“ – 12“ |

| Blind Flanges – Drilled to ASA 150 | 3“ – 12“ |

| Cap – Socket | 3/8“ – 4“ |

| Union – Socket/Plastic to Plastic, EPDM ‘o’ ring | 3/8“ – 4“ |

| Union, Composite – Plastic to Brass, Socket/FPT, EPDM ‘o’ ring | 3/8“ – 2“ |

| Elbow, 90° – Socket | 3/8“ – 12“ |

| Elbow, 45° – Socket | 3/8“ – 12“ |

| Bend, 90° – Short Radius | 1/2“ – 4“ |

| Bend, 90° Long Radius, (4 x D) – Spigot | 3“ – 12“ |

| Bend, 45° Long Radius, (4 x D) – Spigot | 3“ – 12“ |

| Tee, Socket | 3/8“ – 12“ |

| Saddle, Socket | 2“ – 6“ x 1-1/4“ – 2“ |

| Wye, 45° Socket End | 1/2“ – 2“ |

| Wye, 45° Spigot End – Fabricated | 3“ – 12“ |

| Reducer Bushing – Spigot x Socket | 1/2“ – 12“ x 3/8“ – 10“ |

| Reducer Bushing – Spigot x FPT | 1/2“ – 1“ x 3/8“ – 3/4“ |

| Reducer Coupling – Socket | 1/2“ – 12“ x 3/8“ – 10“ |

| Female Adapter – Socket x BSPT | 1/2“ – 2“ |

| Female Adapter – Spigot x BSPT | 1/2“ – 2“ |

| Nipple – Spigot x MPT | 3/8“ – 4“ |

| Plug – M.P.T. | 1/2“ – 2“ |

Suitability of Glycols for Use with ABS

| Heat Transfer Chemical | Chemical Nomenclature | Operating Temperature Range | Maximum Antifreeze Concentration | Suitable Piping System | CAS Number |

| Ethylene Glycol /Monoethylene Glycol | C2H6O2 | -40oF to 176oF(-40oC to 80oC) | Up to 100% | DuraplusABS Industrial | 107-21-1 |

| Diethylene Glycol | O(CH2CH2OH)2 | unsuitable | unsuitable | unsuitable | 111-46-6 |

| Triethylene Glycol | CH2-CH2-O-CH2-CH2-O-CH2-CH2OH OH | unsuitable | unsuitable | unsuitable | 112-27-6 |

| Propylene Glycol /Monopropylene Glycol /1, 2 Propanediol | CH3CH(OH)-CH2OH | -40oF to 176oF(-40oC to 80oC) | Up to 100% | DuraplusABS Industrial | 57-55-6 |

| 1, 3 Propanediol | CH2(CH2OH)2 | -40oF to 176oF(-40oC to 80oC) | Up to 100% | DuraplusABS Industrial | 504-63-2 |

| Dipropylene Glycol | HOC3H6OC3H6OH or H(OC3H6)2OH | unsuitable | unsuitable | unsuitable | 25265-71-8 |

| Tripropylene Glycol | H(OC3H6)3OH | unsuitable | unsuitable | unsuitable | 24800-44-0 |

| Polypropylene Glycol | H[OCH(CH3)CH2]nOH | unsuitable | unsuitable | unsuitable | 25322-69-4 |

| Potassium Formate | KO2CH | -76oF to 122oF | Up to 100% | DuraplusABS Industrial | 590-29-4 |

| Potassium Acetate | C2H3KO2 | -60oF to 122oF | Up to 100% | DuraplusABS Industrial | 127-08-2 |

| Calcium Chloride | CaCl2 | -60oF to 23oF | Up to 100% | DuraplusABS Industrial | 10035-04-8 |

Material Composition

Acrylonitrile-Butadiene-Styrene (ABS) identifies a broad family of engineering thermoplastics with a range of

performance characteristics.

The copolymeric ABS material (resin) can be blended to yield the optimum balance of properties suited to a selected end use. Acrylonitrile imparts chemical resistance and rigidity. Butadiene endows the product with impact strength and toughness, particularly at low temperatures, while Styrene contributes to ease of processing.

The formulation used by IPEX is designed for industrial pressure pipe applications. It has been selected to optimize performance with respect to tensile strength, chemical

resistance, ductility, weatherability, heat stability and processability from raw material to finished product. The resulting pressure piping system is tough, rigid and highly ductile over its recommended operating temperature range of – 40°F (-40°C) to +158°F (70°C).

In addition, the material has good chemical resistance and is easily joined by solvent welding, which allows fast system

assembly and modification.

The outstanding properties of Petronthermoplast ABS are:

- • High-Impact Strength and Ductility

- (which combine to give exceptional toughness)

- • Non-Toxicity

- • Abrasion Resistance

- • Broad Operating Temperature Range

- • Good Chemical Resistance

| Material Property | Unit | Value |

| Ultimate Tensile Strength (strain rate 2 inches/min) 73ºF (22.79ºC) 176ºF (80ºC) | lbf/in2 lbf/in2 | 5,500 3,150 |

| Modulus of Elasticity 73ºF (22.79ºC) 176ºF (80ºC) | lbf/in2 lbf/in2 | 240,000 185,000 |

| Izod Impact Strength (notched) 73ºF (22.79ºC) | ft. lb/in notch | 6 |

| Specific Gravity | – | 1.04 |

* The properties listed in this table represent general

material properties and should be used as a guideline only.

Impact Strength

The impact strength of a material is a measure of its ability to absorb impact energy without failure. Standardized testing methods comply with ASTM, British and ISO standard requirements and involve dropping a tup of known weight onto the pipe from a specified height.

Impact Energy is defined as EI = wh

where, w = weight, lbs.

h = height, ft.

70 ft.lb impact energy is similar to striking the pipe with a 14 lb. hammer from 5 feet. Petronthermoplast ABS is significantly better than most other

thermoplastics at retaining high levels of impact strength at sub-zero temperatures.

Petronthermoplast Industrial Pipe test specimen demonstrates ductility and

impact strength during destructive testing.

Toxicity

Petronthermoplast ABS is free of heavy metallic stabilizers such as lead and chromium. Thus, there are no toxic heavy metals

to leach out into the liquid being conveyed.

Thermal Properties

Thermal properties in chilled water and secondary loop refrigeration are very important to a systems efficiency. Traditional materials like copper or steel are very good conductors and have a thermal conductivity of 2,780 and 305 Btu/in/ft2°F/hr, respectively. This inherent material property causes them to conduct heat very effectively, diminishing the efficiency of a cooling system. Another common problem when using conductive materials for cooling applications is the need for lagging or wrapping to prevent the pipe from sweating. ABS is a non-conductive material and actually acts as an insulator with a thermal conductivity of 1.7 Btu/in/ft2°F/hr. This material property allows for greater process efficiency when used in a cooling system and often eliminates the need for lagging to prevent the pipe from sweating. When a large temperature difference is found between the cooling liquid and the outside temperature, and/or there is a high relative humidity, lagging may be needed even for ABS.

Mode of Failure

Duraplus ABS is a ductile material with a mode of failurethat resembles soft copper. Failure is by ductile distortionand tearing and is localized in nature, which minimizes theloss of the pipe contents.In contrast, the failure of a rigid material is accompaniedby rapid crack propagation and hazardous materialfragmentation.

Depending on the conditions involved, this rapidfragmentation type of failure can rip through many lengthsof pipe, including valves and fittings. This mode of failurecan be accentuated by adverse conditions such as waterhammer, prolonged exposure to sunlight, cold contents orcold ambient temperatures and non-compatibility of thepipe with its contents (eg. compressed air, gases orunsuitable chemicals).

The graph shows the relatively small reduction in impact strength

between ABS at 73°F and 32°F using PVC as a reference point.

Chemical Resistance

| Chemical Group | Relative Strength | Resistance |

| Acids | Weak Medium Strong | Good Good Limited |

| Alkalis | Weak Medium | Good Good |

| Solvents | Strong Organic | Fair No |

Localized ductile failure of Duraplus pipe sample in foreground,

compared with explosive, failure of PVC pipe.

(Both samples charged to 80 psi)

Benefits

IPEX offers matched Duraplus pipes, fittings and valves in IPS sizes ranging from 3/8″ to 12″ nominal diameter, suitable for pressures up to 230 psi at 73°F (23°C) (depending on the size). Besides its operating flexibility, Duraplus offers customers other benefits such as lower costs, durability and performance.

Low Installation Costs

Duraplus ABS pipe reduces costs on a typical installation not only for materials but also for labor and transportation costs when compared to traditional materials. The reason? Its lightweight construction and simple assembly procedures. Like all thermoplastics, Duraplus is easily handled, stored, cut, joined and installed. As a result, project costs for installed Duraplus systems are generally significantly lower. Requirements for heavy equipment are also eliminated.

Improved Flow Characteristics

Duraplus ABS Systems exhibit a substantially lower roughness factor than metals and other materials. In addition, Duraplus does not rust, pit, scale or corrode. As a result, the interior walls of the piping system will remain smooth under virtually all service conditions. These smooth walls allow higher carrying capacities and may enable the use of flatter grades or smaller pipe diameters for a more streamlined design.

Corrosion Resistance

Duraplus ABS Industrial Systems are immune to damage from both naturally corrosive soil conditions and from electrochemical and galvanic corrosion. This is particularly advantageous in underground installations where galvanic reactions often cause damage to metal piping products. These non-corroding properties ensure a long performance life, low maintenance costs and improved flow.

Important:

Only the correct Duraplus Cement will provide a reliable joint. All warranties are null and void if another cement is used. Although a range of threaded fittings is available, note that threading thermoplastic pipe is not always recommended because threading weakens the material. In general, threaded fittings are rated for 180 psi at 73°F (23°C).

Improved Life Expectancy

Duraplus is virtually ageless and impervious to normal weather conditions. Systems that are properly selected for the application, and correctly installed, will provide years of maintenance-free service. Duraplus ABS piping systems have operated successfully in a variety of demanding applications for many years.

During maintenance and equipment upgrades, examinations of original plastic materials have demonstrated both excellent physical and hydraulic wear characteristics. Our materials will not rust, pit, scale or corrode on either interior or exterior surfaces. Unlike other types of piping, Duraplus is not adversely affected by aggressive soil or atmospheric conditions.

Joining Pipe & Fittings

STEP-1

Before beginning, assemble proper materials for the job (IPEX MEK cleaner, Duraplus Industrial ABS cement, and applicator for the size of pipe and fittings to be assembled). Assemble proper Personal Protective Equipment (PPE) for the job (Respirator, safety glasses, gloves and protective clothing).

STEP-2

To make sure that the pipe is cut as square as possible. Use a miter box saw, a power saw with a blade designed to cut plastic or a pipe tube cutter. The blade must be kept sharp. Use a square on the cut end of the pipe to make sure it has been cut squarely. If plastic tubing cutters are used any, raised bead at the end of the pipe must be removed with a file or deburring tool. If not removed it may scrape the cement away during pipe insertion into the fitting during the solvent cementing process.

STEP-3

Use a knife, plastic pipe deburring tool, or file to remove burrs from the end of small diameter pipe. Be sure to remove all burrs from around the inside as well as the outside of the pipe. A slight chamfer (bevel) of about 15° should be added to the end to permit easier insertion of the pipe into the fitting. Failure to chamfer the edge of the pipe may remove cement from the fitting socket, causing the joint to leak. For systems of 2″ and above, the pipe must be end-treated with a 15° chamfer cut to a depth of approximately 3/32″ (2.5mm). If burrs are not removed, they can scrape channels into surface of the fitting socket during solvent welding.

STEP-4

Use a knife, plastic pipe deburring tool, or file to remove burrs from the end of small diameter pipe. Be sure to remove all burrs from around the inside as well as the outside of the pipe. A slight chamfer (bevel) of about 15° should be added to the end to permit easier insertion of the pipe into the fitting. Failure to chamfer the edge of the pipe may remove cement from the fitting socket, causing the joint to leak. For systems of 2″ and above, the pipe must be end-treated with a 15° chamfer cut to a depth of approximately 3/32″ (2.5mm). If burrs are not removed, they can scrape channels into surface of the fitting socket during solvent welding.

STEP-5

Before solvent welding make sure there is an interference fit between the pipe and fitting socket. Pipe should be able to be inserted 1/3 to 2/3 the way into the socket before an interference fit is encountered. If the pipe goes all the way into the socket do not use. Set aside and use another fitting. Contact your pipe and fitting supplier for replacement.

STEP-6

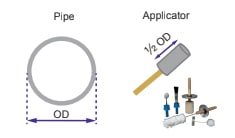

Measure the fitting socket depth. This distance will then be used to draw a line on the OD of the pipe.

STEP-7

Mark this distance (fitting socket depth) on the pipe OD, 1ST Mark.

Cleaner and solvent cement will eventually cover the end of the pipe up to this line.

STEP-8

Make a 2nd Mark on the pipe OD. The distance, from the second mark to the 1st Mark should be the same as the fitting socket depth.

This is used to check that the pipe is bottomed out (properly inserted) in the fitting socket after solvent welding.

STEP-9

It is critical that the right size applicator be used on the pipe and fitting being solvent welded. The applicator should be 1/2 the size of the pipe diameter (for example; use a 2″ applicator on a 4″ pipe). The right size applicator will ensure that sufficient quantity of cement is applied to the pipe and fitting socket.

STEP-10

Using a clean dry rag, or applicator to apply the cleaner into fitting socket, keeping the surface and applicator wet until the surface has been cleaned. When the surface is cleaned, quickly remove any puddles of cleaner from the socket.

STEP-11

Next, apply the cleaner to the end of the pipe. Cleaner should be applied approximately 1/2″ beyond the 1st mark (1/2″ beyond the depth of the fitting socket).

STEP-12

Immediately apply a medium even layer of solvent cement into the fitting socket; aggressively work the solvent cement into the socket wall without allowing the cement in the socket to puddle.

STEP-13

Immediately, apply a second, full even layer of solvent cement on the pipe wall.

NOTE: The majority of joint failures are a result of improper or insufficient application of solvent cement.

STEP-14

Without delay, while cement is still wet, insert the pipe into the fitting socket. While inserting the pipe in the fitting socket, twist the pipe 1/8 to 1/4 turn until reaching socket bottom.

NOTE: If cement coatings have hardened, cut off pipe end and dispose of fitting and start over. Do not attempt to assemble pipe or fittings with partially cured surfaces. Do not continue to rotate after the pipe has reached the socket bottom. Securely hold the pipe and fitting assembly together, for a minimum of 30 seconds to eliminate push-out or movement.

NOTE: After assembly, a joint should have a clean ring or bead of cement completely around the mouth of

the fitting socket. Note, if voids (gaps) in this ring are present, sufficient cement was not applied which

can be an indicator of a weak joint.

GET THE LATEST ABS Plastic Pipes Manufacture PRICES ON YOUR EMAIL