Description

Nylon material is a strong, stiff engineering plastic with outstanding bearing and wear properties. Nylon is frequently used to replace metal bearings and bushings often eliminating the need for external lubrication. Other benefits include a reduction in part weight, less operating noise, and decreased wear on mating parts.

Shop for Nylon >

STANDARD SIZES

| SHEET |

|---|

| Dimensions: 12 in x 12 in – 48 in x 120 in |

| Thickness: 0.031 in – 4 inNote: Type 6-Cast and Type 6/6-Extruded Sizes Vary |

OPTIONS AVAILABLE

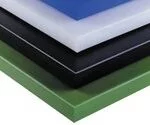

| COLOR |

|---|

| Sheet and Rod: Natural, Green, BlackTube: Natural, Black |

| GRADES |

|---|

| Unfilled, Glass-Filled, Oil-Filled, MOS2 |

| ROD |

|---|

| Outside Diameter: 0.187 in – 13 in |

| TUBE |

|---|

| Outside Diameter: 2 in – 5 in |

NYLON IS WIDELY USED FOR:

- Bearings and bushings

- Gears

- Wear pads

- Packaging machinery parts

- Food processing machinery parts

- Wheels

- Rollers

- Seals and gaskets

PERFORMANCE CHARACTERISTICS:

- Excellent bearing and wear properties

- Strong and stiff

- Good chemical resistance

- Easy to machine

- Easy to fabricate

- Reduced noise, weight, and wear of mating parts

COMMON BRANDS:

- SUSTAMID® M

- TECAMID®

- NYCAST®

Length, width, thickness, and diameter tolerances vary by size, by manufacturer, brand, and grade. Custom sizes and colors available upon request. Also available as a tape.

Nylon Properties and Material Options

Nylons are typically described according to numbers (6, 66, 11, 12, etc.) which relate to their molecular structures. Although there are many types of Nylon, the two most common available in sheet, rod, and tube are Nylon 6 and Nylon 6/6.

Nylon 6 and Nylon 6/6– have very similar mechanical, thermal, and electrical properties. Both are available in a variety of colors and formulations that are engineered to meet specific application requirements. For Nylon 6 chemical resistance view our chart.

Nylon 6– is generally manufactured into sheet, rod, and tube via a liquid casting process. Casting is often the most cost effective method for producing large diameter rod, tube, and thick sheet. This process has the added advantage of allowing manufacturers to create custom near net (irregular) shapes. Near net shapes are useful in the construction of parts that would yield poorly from standard sheet, rod, or tube stock.

Nylon 6/6– sheet, rod, and tube are usually produced by melting solid pellets of the polymer and processing them through a thermoplastic extruder. Extrusion is a fast and economical method for making small diameter rod, tube, and thin sheet. Unlike cast Nylon 6 stock shapes, extruded Nylon 6/6 sheet, rod, and tubing can be manufactured to any length, which can be an advantage for cost effectively yielding finished parts.

Nylon Grades– Nylon is available in a variety of specialty formulas. Molybdenum disulphide-filled (MOS2) and oil-filled nylons have enhanced wear properties often eliminating the need for external lubrication. Heat-stabilized nylon withstands higher operating temperatures. Nylon is available in glass-filled grades for enhanced stiffness and strength. FDA compliant grades of nylon are available for direct food contact.

Nylon with Metal Core– Nylon billets can be manufactured into many different components including gears, rollers, sprockets and augers. In power transmission applications, NYMETAL® billets combine the performance advantages of nylon and metal into one cohesive unit.

Tech Tip– Nylon has relatively high moisture absorption compared with many other thermoplastics. Nylon parts that must perform in wet environments should be designed with tolerances that factor in dimensional changes due to moisture absorption.

TYPICAL PROPERTIES OF UHMW

| UNITS | ASTM TEST | EXTRUDED NYLON 6/6 | CAST NYLON 6 | MD-FILLED CAST NYLON 6 | OIL-FILLED CAST NYLON 6 | |

|---|---|---|---|---|---|---|

| Tensile strength | psi | D638 | 12,400 | 10,000 – 13,500 | 10,000 – 14,000 | 9,500 – 11,000 |

| Flexural modulus | psi | D790 | 410,000 | 420,000 – 500,000 | 400,000 – 500,000 | 375,000 – 475,000 |

| Izod impact (notched) | ft-lbs/in of notch | D256 | 1.2 | 0.7 – 0.9 | – | 1.4 – 1.8 |

| Heat deflection temperature @ 264 psi | °F | D648 | 194 | 200 – 400 | 200 – 470 | 200 – 400 |

| Maximum continuous service temperature in air | °F | 210 | 230 | – | 230 | |

| Water absorption (immersion 24 hours) | % | D570 | 1.20 | 0.60 – 1.20 | 0.05 – 1.40 | 0.50 – 0.60 |

| Coefficient of linear thermal expansion | in/in/°Fx10-5 | D696 | 4.5 | 5.0 | – | 5.0 |

| Coefficient of linear friction (dynamic) | 0.28 | 0.22 | 0.30 | 0.12 |

Values may vary according to brand name. Please ask your Curbell Plastics representative for more specific information about an individual brand. *Double-15° notch

Nylon bushings

Nylon is one of the plastics used to make polymer bushings. Nylon bushings are injection moulded or cast, which is why they are referred to as moulded bushings. They are typically available as sleeved or flanged bushings. We’ll look at some facts about a specific type of Nylon Bushings.

Major Characteristics

Surface Properties:

Nylon bushings are self-lubricating, which implies these don’t need to be lubricated. They have a remarkably low coefficient of friction as well. As a result, they are essentially zero-maintenance bushings.

Strength and Performance:

Non-reinforced Nylon bushings have a PV (pressure-velocity) rating of 3000 ft/min/psi. Furthermore, when compared to their metal counterparts, they are extremely lightweight.

Chemical Resistance:

Some nylons perform exceptionally well in the presence of hydrocarbons and alcohols. Strong acids are their greatest weakness. Nylon is chemically resistant to weak acids, alkalis, organic solvents, and most fuels.

Nylon Material

Nylon is a synthetic thermoplastic linear polyamide, a large molecule whose constituents are held together by a specific type of bond.

Nylon material are used in many applications, including clothing, rubber reinforcement such as car tyres, rope or thread, and many injections moulded parts for automobiles and mechanical components. It is extremely strong, relatively resistant to abrasion and moisture absorption, long-lasting, chemical-resistant, elastic, and simple to clean.

Because of its strength, temperature resistance, and chemical compatibility, it is the plastic of preference for components in vehicle engine compartments.

Bushing plastic

Composite plastic bushings are made up of thermoplastic alloys, solid lubricants, and a fibre matrix for reinforcement. Applications with higher temperatures or higher loads are made from various low-cost plastics. Many bushing plastics used to make bushings are less expensive than comparable metals.

Nylon Polyamide 66

Nylon 66 is a synthetic polymer known as polyamide, with the numbers describing the type and number of polymer chains in its chemical structure. Most nylons, including 66, are semi-crystalline and have high strength and durability in demanding applications.

It possesses exceptional mechanical strength, stiffness, hardness, and toughness. Nylon 66 has better fatigue tolerance, mechanical damping ability, and wear resistance, among other properties.

Explore the physical, mechanical, thermal, electrical, and optical properties of nylon.

Sort, compare, and find the plastic material suited for your application using our interactive properties table.

EXPLORE OTHER PRODUCTS & SERVICES

Acetal

UHMW

HDPE

DuPont™ Vespel® Polyimide

PEEK