HDPE Pipe Fittings

HDPE PIPE FITTINGS

HDPE Pipe Fitting Manufacturer in India are the best manufacturer that offers HDPE pipes and fittings.

Best HDPE pipes are best for agricultural purposes such as Drip and Sprinkler Irrigation techniques, pump and passing water systems. They are even used for supplying drinking water, industrial purposes such as groundwater pipes, sewage or radioactive waste handling, and underground cable passage.

HDPE pipes fittings are found in 20 to 450mm in measurement. These pipes are given in PN 2.5 to PN 16 pressure group in PE 63, PE 80, and PE 100 score. Also, these pipes are manufactured as per to IS: 4984.

HDPE PIPE FITTINGS

What is HDPE Pipe Fitting

HDPE stands for High-density polyethylene. It also stands for polyethylene high-density (PEHD). It is a thermoplastic polymer that is usually originated out of monomer ethylene, also known as alkenes or polythene while utilized in the best HDPE pipe fitting.

HDPE is a smooth and elastic-plastic that creates the Best HDPE pipe perfect for handling reduced pressure, compressed curved radius conditions.

HDPE Pipes or Polyethylene (PE pipes) are classified by strength as per the magnitude of the previous technological advancement. Among the most preferred pipe in the world is HDPE pipes. As the technique of HDPE is way cheaper and simple to maintain with high-efficiency and simple procedure of integrating.

Why Choose Petron Thermoplast

Petron Thermoplast is a well-known brand in the field of HDPE pipes. HDPE (High-Density Polyethylene) pipes are widely used for various applications, such as water supply, gas distribution, sewage disposal, and more. Petron Thermoplast offers high-quality HDPE pipe fittings that are durable, strong, and resistant to corrosion and abrasion.

One of the main reasons to choose Petron Thermoplast for HDPE pipes is their expertise in manufacturing and supplying these pipes. They use advanced technology and high-grade raw materials to produce HDPE pipes that meet international quality standards. Their pipes are tested for various parameters, such as strength, flexibility, and leak resistance, before being dispatched to customers.

Another reason to choose Petron Thermoplast is their commitment to customer satisfaction. They provide excellent after-sales service and technical support to their customers. Their team of experts can assist customers with the installation, maintenance, and repair of HDPE pipes.

Overall, if you are looking for reliable, high-quality HDPE pipes for your project, Petron Thermoplast is a brand that you can trust.

HDPE Pipe Joint Types

HDPE (High-Density Polyethylene) pipes can be joined together using different methods depending on the application and the design requirements. Here are some of the common HDPE pipe joint types:

- Butt Fusion: Butt fusion is the most common method used for joining HDPE pipes. It involves heating the ends of the pipes and then fusing them together under pressure. This creates a strong, leak-proof joint.

- Electrofusion: Electrofusion is another popular method for joining HDPE pipes. It uses an electric current to heat a wire coil embedded in the pipe fittings. The melted pipe material fuses the joint together.

- Socket Fusion: Socket fusion is a method used for smaller diameter pipes. It involves heating the pipe and the fitting and then pushing them together to create a fusion joint.

- Mechanical Coupling: Mechanical couplings are used to join two HDPE pipes by means of a mechanical joint. This method requires no heat or electricity, and the joint can be easily disconnected for repairs or maintenance.

- Flanged Joint: Flanged joints are used in applications where the pipe needs to be easily disconnected for maintenance or repairs. The joint is created by bolting two flanges together with a gasket in between.

Each of these HDPE pipe joint types has its own advantages and disadvantages. The joint type that is best suited for a particular application depends on factors such as pipe size, pressure, and temperature requirements.

Fittings to Use with HDPE pipe

Here are some of the common fittings used with HDPE pipes:

- Butt Fusion Fittings: Butt fusion fittings are the most common type of fitting used with HDPE pipes. These fittings are used to join two HDPE pipes together by heating the ends of the pipes and fusing them together under pressure.

- Electrofusion Fittings: Electrofusion fittings are another popular type of fitting used with HDPE pipes. They use an electric current to heat a wire coil embedded in the fitting, which melts the material and fuses the fitting to the pipe.

- Compression Fittings: Compression fittings are used to join HDPE pipes together without the need for heat or specialized tools. They consist of a threaded fitting that compresses a gasket onto the pipe to create a tight seal.

- Transition Fittings: Transition fittings are used to connect HDPE pipes to other types of pipes or fittings, such as PVC or metal pipes. They typically have a flange or a threaded connection on one end and a fusion joint on the other.

- Flange Adapters: Flange adapters are used to join HDPE pipes to other pipes or fittings that have flanges. They consist of a flange that is fusion-bonded to the HDPE pipe and a metal flange that bolts onto the other pipe or fitting.

- Saddles: Saddles are used to tap into an existing HDPE pipe for a branch connection. They typically have a fusion joint on one end and a threaded or flanged connection on the other.

HDPE Pipe Fittings Range

What are the application of HDPE pipe and fittings?

The third generation HDPE 100 raw materials are utilized in making potable water pipelines, remove salt and minerals present in plants, natural treatment of plants, swimming pool piping, sea discharge pipes, water flow pipes, gas stations, irrigation pipes, pressure air pipes, cooling-heating lines, insulated pipes.

What are the different types of HDPE pipe available?

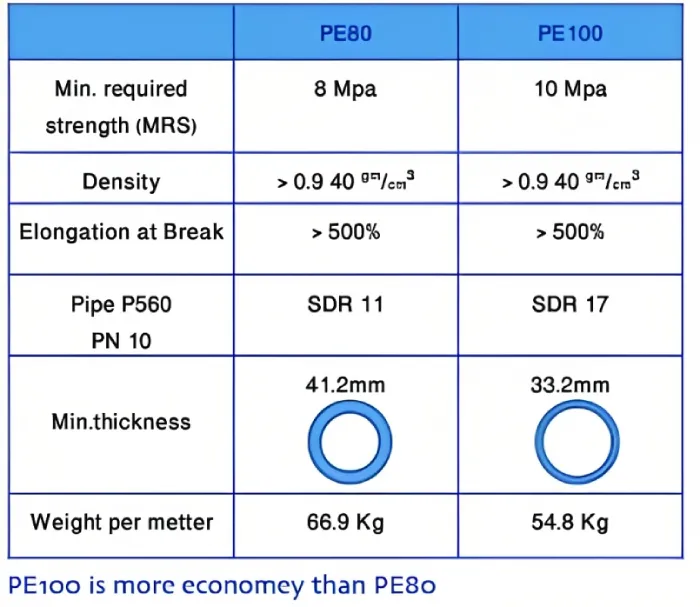

High concentrated HDPE pipes have been graded as the concentrated or density value. HDPE 80 and HDPE 100 pipes are distinct at present due to the last generation of the advanced HDPE substances. PE 100 pipe currently has the highest density which indicates its strength, firmness, and toughness as compared to PE 80 pipe.

How do you integrate HDPE pipe into HDPE pipe?

The heat of transformation is the widely preferred method for integrating HDPE pipe. It has to be done using the heating of the ends of both pipes and compressing them jointly. Thus, forming a long-lasting joint that transforms a single part of pipe into an individual and persistent bar.

HDPE review

The PE raw material has three generations that started early in 1950 with PE32 &PE63 as 1st generation, 2nd generation, is PE80, and the last & 3rd generation is PE100early in 1990 which has high performance and economical solution for all application also that stands & that’s suitable for different applications (drinking water, sewage, natural gas..etc…) to ight the other traditional pipes. The main diきerence between PE80 & PE100 (both PE80 and PE100 is high density polyethylene).

The main difference between PE80 & PE100

(Both PE80 and PE100 are high density polyethylene)

Advantages of GM PE Pipes

1. High lexibility which allows the network Pipes for elbows to save cost.

2. Excellent traffic load resistance due to its structure which speciied as visco_elestic material.

3. PE pipes networks are leakage free as a results for joining by butt fusion welding which form the network as one pipe.

4. Excellent impact resistance.

5. Small pipes diameters deliver in coils which save time and installation cost.

6. Less installation cost due to carrying out all pipe welding outside the trench.

7. Excellent water hammer resistance compared with other type of pipes, the HDPE pipes have visco_elastic beviour which allow the pipe to reteurn back to original shape without any efect.

8. His not afected by harmful material exicted structure of soil for that is not need to cathodic protection.

9. HDPE ittings don,t need thrust blocks.

10. High resistance for chemicals at different temperature (see tables).

11. Excellent compatibility with leiting soil.

12. Excellent resistance to U.V Radiation.

13. High abrasion resistance

14. Do not change the adour and taste of water, for that it is considered healthy.

15. It is impossible for plant and tree roots to enter in the pipes.

16. Appropriate for under water installation and are not affected by sea water or sea movements.

17. Quick installation.

18. Continuous work without any problem at nominal working pressure for minimum of 50 years.

Different uses for PE pipes

Water Networks:

GM HDPE pipes are used for potable water networks which its not affecting the water properties or validity, as it is chemically inert. In addition, the networks are totally safe and very secure from any leakage problems resulted from water hammering due to the joining methods using butt fusion welding and its high lexibility.

The smooth surface which prevents any kind of bacteria to accumulate makes GM pipes is the most suitable choice when dealing with potable water

Sanitary and industrial drainage:

GM HDPE pipes are used for both sanitary and industrial drainage due to their excellent chemical resistance for (Acids, Alkaline, Salts, ..etc) and their non-penetration nature, besides the network leakage free.

Fire fighting system:

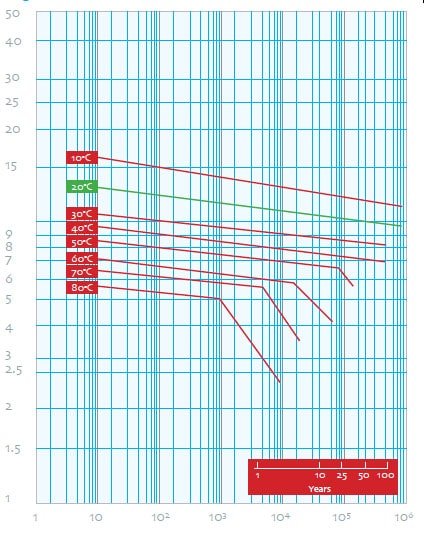

Fire ighting networks suffer from water hammer due to sudden opening and closing valves therefore, HDPE pipes are suitable for these networks with their high resistance for water hammer, this phenomenon (water hammer) has been taken into consideration while drawing regression Curve, which decided the life of HDPE pipes as 50 years (see Chart o1 & .02).

Irrigation flexibility:

Die to lexibility, GM HDPE pipes that one high resistance for environmental conditions, especially ultraviolet rays. Same as PE pipes. One considered the optimum choice for irrigation networks by using it up ground and under ground.

Natural gas networks:

There is no alternative for PE pipes in natural gas networks for their high security levels. The medium density polyethylene (MDPE) PE 80 yellow colour are used up to 5.5 bar according to PL2 – 1. GM HDPE (PE 100) pipes with orange color are used with working pressure up to 7.0 Bar according to PL2 – 8. The feeding lines of PE pipes also can be squeezed o in order to stop gas low during repair & release it again after

repairing, according to the regulations of each country.

Other uses:

– Siphons under canals, railway lines & aircraft runways where the pipes are

installed by directional drilling.

– Cables ducts.

– Water injection system of oil wells.

Food stuff transmission lines:

GM (HDPE) pipes are used in foodstu transmission as (milk products and corns).

Log scale:

Chart 01 Endurance Diagram of PE 80 Pipes According to Temperature

Log scale:

Chart 02 Endurance Diagram of PE 100 Pipes According to Temperature

How to describe PE pipes:

• PE Pipes are described with outside diameters according to GM catalogue or international standards.

• Decide the type of HDPE {PE 80 (MRS* 8.0 Mpa) or PE 100 (MRS* 10.0 MPA)}

• Dicted the mean out side diameter.

• Then the working pressure is speciied directly from the table of dimensions or by using SDR**

(SDR**) = MEAN OUTSIDE DIMAETER

———————————–

MINIMUM THICKNESS

• *MRS: min. required strength

• **SRS: Standard dimension ratio

Standards

– Potable Water, Sanitary and industrial Drainage, Fire ighting Networks,..etc the DIN 8074 / 75, EN 1221, ASTM, ISO & Egyptian Standards can be applied.

– For Natural Gas Networks BGC PL2 – 1 / 8

Conclusion

HDPE Pipe Fittings are among the best pipes to consider. It holds within the extensive properties of the liquid. It offers high resistance to chemicals. Thus, it owns excessive properties of binding that can be used where natural hazardous like earthquake takes place.

Consult the best HDPE Pipe Fitting Manufacturer in India.

GET THE LATEST HDPE Pipe Fittings PRICES ON YOUR EMAIL