PEEK Materials (Polyetheretheretherketone)

PEEK Material (Polyetheretheretherketone), it is a high-performance engineering plastic with exceptional chemical resistance, mechanical strength, and dimensional stability. It is resistant to steam, water, and seawater hydrolysis.

PEEK sheet has the capacity to keep rigidity at high temperatures and may be used indefinitely at temperatures up to 338 degrees Fahrenheit (170oC). This technical plastic has a long history of success in demanding applications such as aerospace, oil and gas, food and beverage processing, and semiconductors.

PEEK Material properties used to produce products utilised in demanding applications, such as bearings, piston components, pumps, HPLC columns, compressor plate valves, and cable insulation, because to its toughness. It’s one of the few polymers that can withstand ultra-high vacuum.

PEEK IS WIDELY USED FOR:

- Semiconductor machinery components

- Aerospace parts

- Bushings, bearings, seals, and back-up rings

- Pump and valve components

- Vacuum wand handles

- Down hole electrical connectors

- Medical instrument parts

- Food processing machinery components

PERFORMANCE CHARACTERISTICS:

- Strong and stiff

- Chemical resistant, hydrolysis resistant, autoclavable

- Easy to machine and fabricate

- Good mechanical properties at elevated temperatures

- UL 94 V-0 flammability rating (0.059″ thickness)

- Very low smoke and toxic gas emissions when exposed to flame

COMMON BRANDS:

- TECAPEEK®

- SustaPEEK

- Ketron®

STANDARD SIZES

| SHEET | Dimensions: 6 in x 6 in – 24 in x 48 in |

| Thickness: 0.250 in – 4 in |

| ROD | Outside Diameter: 0.187 in – 6 in |

| TUBE | Outside Diameter: 30 mm – 210 mm |

OPTIONS AVAILABLE

| COLOR | Natural, Black, Dark Blue |

| GRADES | Glass-Filled, Bearing Grades, FDA Compliant, Metal and X-ray Detectable |

PEEK Properties and Material Options

Virgin PEEK (unfilled)– is naturally abrasion resistant. Glass-Filled PEEK– offers enhanced mechanical and thermal properties over those of basic PEEK, plus excellent resistance in harsh chemical environments and is electrically insulative. Bearing Grade PEEK– has enhanced bearing and wear properties. TECAPEEK® PVX is an ultra high performance bearing material with wear enhancing additives. FDA Compliant PEEK– grades available that meet FDA requirements. Optical, Metal and X-ray Detectable PEEK– TECAPEEK® UD is a dark blue FDA compliant detectable PEEK designed for the food and beverage processing and pharmaceutical industries. This metal and x-ray detectable material has a heat deflection temperature of over 300°F and excellent resistance to a wide range of cleaning chemicals. Tech Tip– When polymers are required for applications that involve large changes in temperature, best practices involve selecting a filled grade of a stable (low CTE) base polymer. When fillers are added to highly stable base polymers such as VICTREX® PEEK, the resulting composites exhibit extremely low CTE values, which makes PEEK a good candidate for applications requiring plastics with CTEs as close as possible to those of metals.TYPICAL PROPERTIES OF HDPE

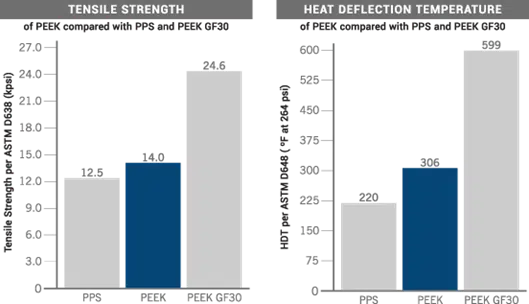

| UNITS | ASTM TEST | PEEK | PEEK 30% GLASS-FILLED | |

|---|---|---|---|---|

| Tensile strength | psi | D638 | 14,000 | 24,620 |

| Flexural modulus | psi | D790 | 590,000 | 1,450,000 |

| Izod impact (notched) | ft-lbs/in of notch | D256 | 1.6 | 1.84 |

| Heat deflection temperature @ 264 psi | °F | D648 | 306 | 599 |

| Maximum continuous service temperature in air | °F | 480 | 482 | |

| Water absorption (immersion 24 hours) | % | D570 | 0.50 | 0.11 |

| Coefficient of linear thermal expansion | in/in/°Fx10-5 | D696 | 2.6 | 1.2 |

| Coefficient of friction (dynamic) | 0.25 | 0.30 |

Please ask your Petron Thermoplast representative for more specific information about an individual brand.

Explore the physical, mechanical, thermal, electrical, and optical properties of PEEK.

Sort, compare, and find the plastic material suited for your application using our interactive properties table.

PEEK PROPERTIES COMPARISON GRAPHS