Introduction to CPVC Pipes

CPVC (Chlorinated Polyvinyl Chloride) pipes are a type of thermoplastic known for their versatility and efficiency in plumbing. Specifically engineered for handling both cold and hot water, CPVC pipes have distinct properties that make them suitable for various applications.

Properties of CPVC Pipes

Heat Resistance

CPVC Pipes are renowned for their exceptional ability to withstand high temperatures. They can maintain their structural integrity even when exposed to elevated heat, ensuring a consistent flow of hot water without any deformation or compromise in performance.

Durability

One of the key advantages of CPVC pipes is their remarkable durability. They possess resistance against corrosion, scaling, and rust, guaranteeing a prolonged lifespan. This durability makes them a cost-effective solution for plumbing systems, especially those involving hot water.

Chemical Resistance

CPVC pipes exhibit excellent resistance to various chemicals, making them suitable for a wide range of applications. This resistance ensures that CPVC pipes remain robust and unaffected even in environments with chemical exposure, maintaining their performance over time.

Smooth Surface

These pipes feature a smooth interior surface, which not only aids in efficient water flow but also prevents the build-up of deposits, ensuring consistent water quality and system efficiency.

Impact Resistance

CPVC pipes are also known for their ability to withstand impact, making them less prone to damage during transportation, handling, or installation. This resilience contributes to their overall reliability and longevity in plumbing systems.

Flexibility

While being sturdy and robust, CPVC pipes also offer a degree of flexibility, allowing for easier installation and adaptation to various plumbing layouts and requirements.

These properties collectively make CPVC pipes a preferred choice for plumbing systems, particularly in scenarios where the handling of hot water is involved, due to their ability to maintain structural integrity, durability, and efficiency even at high temperatures. CPVC Pipe Fittings Manufacturers and Suppliers in India.

CPVC Pipe Applications

CPVC (Chlorinated Polyvinyl Chloride) pipes find extensive use across various settings due to their versatile properties. Specifically, they excel in applications involving both cold and hot water. These pipes are commonly employed in:

- Residential buildings for potable water supply.

- Commercial establishments such as hotels, hospitals, and schools.

- Industrial environments for processing and conveying fluids.

- Irrigation systems for agriculture.

- Fire suppression systems are due to their fire-resistant nature.

- Their ability to handle elevated temperatures without compromising performance makes CPVC pipes ideal for hot water systems, ensuring a reliable and efficient flow of hot water.

Choosing the Right CPVC Pipe for Hot Water

Selecting the appropriate CPVC pipe for hot water systems involves considering several crucial factors:

- Temperature and Pressure Ratings: Ensure the CPVC pipe’s specifications match the intended hot water application. Different pipes have varying temperature and pressure ratings, and choosing the right one is vital for safety and efficiency.

- Standards Compliance: Verify that the CPVC pipe complies with industry standards and certifications to guarantee its suitability for hot water usage.

- Sizing Considerations: Determine the required size of the CPVC pipe based on the hot water system’s flow requirements, ensuring optimal performance.

- Manufacturers provide a range of CPVC pipes with diverse specifications, offering options tailored to different hot water needs.

Benefits of Using CPVC Pipes for Hot Water

Using CPVC pipes for hot water systems offers several advantages:

- Efficiency: CPVC pipes minimize heat loss in hot water systems, contributing to energy efficiency. Their smooth interior surface ensures excellent water flow, enhancing overall system performance.

- Durability and Reliability: These pipes exhibit exceptional durability, resisting corrosion, rust, and chemical reactions. Their longevity ensures a continuous and reliable supply of hot water without degradation.

- Cost-effectiveness: CPVC pipes are cost-effective compared to traditional metal pipes. They require less maintenance and have a longer lifespan, reducing overall maintenance and replacement expenses.

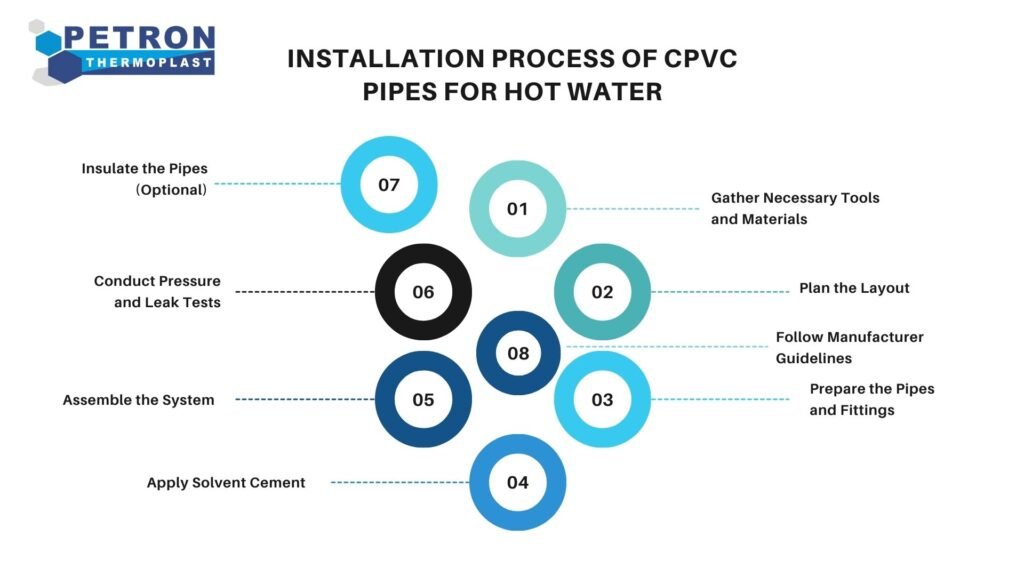

Installation Process of CPVC Pipes for Hot Water

Installing CPVC pipes for hot water systems requires adherence to specific steps and considerations to ensure a secure and efficient setup:

- Gather Necessary Tools and Materials

Before beginning the installation process, gather the following tools and materials:

- CPVC pipes of the appropriate size and specifications.

- CPVC solvent cement.

- CPVC fittings (couplings, elbows, tees, etc.).

- CPVC pipe cutter.

- Measuring tape and marker.

- Sandpaper or emery cloth for surface preparation.

- Rag for cleaning.

- Plan the Layout

Design the layout for the CPVC piping system, considering the hot water source, fixtures, and necessary connections. Measure and mark where the pipes will be installed, ensuring accuracy and proper alignment. - Prepare the Pipes and Fittings

Cut the CPVC pipes to the required lengths using a CPVC pipe cutter. Ensure clean, square cuts for proper fittings.

Use sandpaper or emery cloth to lightly sand the outside ends of the pipes and the inside of the fittings to remove any roughness and ensure proper adhesion. - Apply Solvent Cement

Apply CPVC solvent cement to both the outside end of the pipe and the inside of the fitting.

Quickly insert the pipe into the fitting, giving it a slight twist to ensure a secure and even bond.

Hold the joint firmly for a few seconds to allow the solvent cement to set and create a strong connection. Avoid disturbing the joint until the cement fully cures. - Assemble the System

Continue assembling the CPVC piping system, following the planned layout and connecting the pipes and fittings as per the design.

Support the pipes adequately with straps or hangers at regular intervals to prevent sagging and ensure stability. - Conduct Pressure and Leak Tests

After completing the installation, conduct pressure and leak tests to ensure the integrity of the CPVC piping system. Pressurize the system and check for any leaks at joints or connections. Address any leaks promptly by reapplying solvent cement if needed. - Insulate the Pipes (Optional)

Consider insulating the CPVC pipes, especially in colder environments, to prevent heat loss and maintain water temperature. - Follow Manufacturer Guidelines

Always follow the machined components manufacturer guidelines and recommendations for installation, including temperature and curing times for solvent cement, to ensure a proper and leak-free CPVC piping system for hot water.

Adhering to these installation steps and best practices ensures a reliable and efficient CPVC piping system specifically designed for hot water applications.

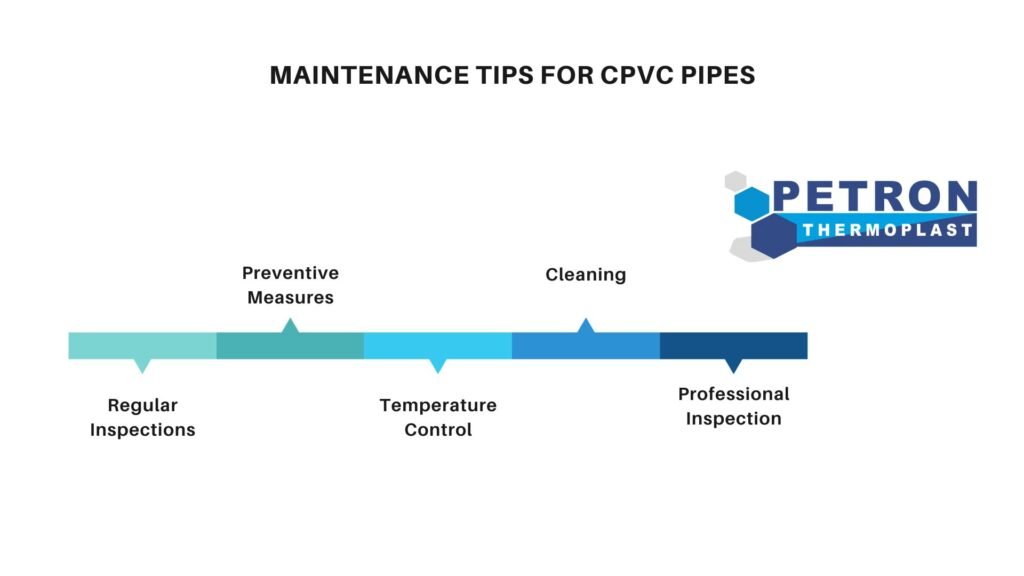

Maintenance Tips for CPVC Pipes

Maintaining CPVC Pipes is essential to ensure their longevity and optimal performance in hot water systems. Consider the following maintenance tips:

- Regular Inspections

Periodically inspect CPVC pipes for any signs of leaks, cracks, or damage. Address any issues promptly to prevent further deterioration. - Preventive Measures

Implement preventive measures to safeguard CPVC pipes, such as protecting them from physical damage or exposure to harsh chemicals. - Temperature Control

Maintain appropriate water temperatures within the recommended range for CPVC pipes to ensure their durability and prevent potential damage from excessive heat. - Cleaning

Keep CPVC pipes clean from debris or sediment buildup that could affect water flow. Use mild cleaning solutions and avoid abrasive materials that could damage the pipes. - Professional Inspection

Consider scheduling periodic inspections by plumbing professionals to assess the condition of CPVC pipes and address any underlying issues.

Future Prospects of CPVC Pipes

The future of CPVC Pipes in the plumbing industry holds promising advancements and innovations:

- Technological Innovations

Ongoing research and development efforts aim to enhance CPVC technology, introducing improved formulations and manufacturing techniques. - Enhanced Performance

Future advancements are expected to further improve CPVC pipes’ heat resistance, durability, and overall performance, making them more efficient and reliable for hot water applications. - Market Trends

The increasing demand for sustainable and cost-effective plumbing solutions is likely to drive the growth of CPVC pipes in various sectors, including residential, commercial, and industrial applications. - Environmental Considerations

CPVC’s recyclability and eco-friendly nature contribute to its continued relevance in an environmentally conscious world, making it a sustainable choice for plumbing systems. - Industry Standards and Regulations

CPVC pipes are anticipated to align with evolving industry standards and regulations, ensuring compliance and safety in plumbing installations.

In summary, the future prospects of CPVC pipes involve continuous improvements in technology, performance, sustainability, and compliance with industry standards, reinforcing their position as a reliable and efficient choice for hot water plumbing systems.

Conclusion

In conclusion, CPVC pipes are an excellent choice for hot water systems due to their heat resistance, durability, and efficiency. Selecting the right CPVC pipe involves considering factors like temperature ratings, standards compliance, and sizing. With proper installation and maintenance, CPVC pipes ensure a reliable and long-lasting hot water supply.

FAQs

- Are CPVC pipes suitable for outdoor hot water applications?

- Yes, CPVC pipes can be used for outdoor hot water systems. However, it’s essential to protect the pipes from prolonged exposure to direct sunlight to prevent potential degradation due to UV rays.

- Can CPVC pipes be used for both cold and hot water systems?

- Absolutely. CPVC pipes are designed to handle both cold and hot water, making them versatile for various plumbing applications.

- What are the potential drawbacks of using CPVC pipes for hot water?

- While CPVC pipes offer numerous advantages, including durability and resistance to corrosion, they can potentially degrade when exposed to extremely high temperatures above their specified limits. Ensuring proper temperature control is crucial to prevent any issues.

- Do CPVC pipes require insulation for hot water applications?

- Insulation for CPVC pipes in hot water systems is recommended, especially in colder environments, to prevent heat loss and maintain water temperature. However, CPVC inherently has some insulating properties.

- Are there specific tools needed for installing CPVC pipes for hot water?

- Yes, some essential tools include a CPVC pipe cutter, solvent cement, fittings, measuring tape, sandpaper or emery cloth for surface preparation, and straps or hangers for supporting the pipes.