PPH Wafer Check Valve

PPH Wafer Check Valve Manufacturer in India. As a safety filter, the sediment sieve is meant to capture any solid contaminants that may sometimes be in the line. We export valves and other equipment with small holes, such as pumps or control valves, protected by it. The filter screen is easily replaceable and available in a variety of meshes.

An oscillating disc is used to open or close the valve. As a result of their design, they can be installed in extremely tight spaces where a flanged check valve would be ineffective. As the disc opens, the PPH wafer check valve has a molded body surrounding the opening.

In contrast, PPH wafer check valves have a molded body that enables the disc to fully open, enabling full flow.

In the case of applications that demand full flow, this is an important consideration, as you can see. Therefore, wafer check valves are used in situations where flow is not a concern. Swing checks are used in applications where a full port valve is required.

PPH Valves

Custom Product Manufacturing Available

If you are searching for customized product designs that meet your requirements, don’t worry. Petron Thermoplast also offers custom product manufacturing services to meet the unique needs of various industries. Work with our expert engineers to create custom designs suited for your application.

Get Quick Information

The CR wafer check valve is designed to be installed directly between stubs and flanges in accordance with ISO/DIN standards.

• Installed with FIP QPV (d50 – d160) stubs and QRV stubs using flat gasket QHV/Y (d225 – d315), on PVC piping class PN10 or lower with type ODV flanges

• Metal support for easy and precise centring of the valve during installation

• Can be installed in either a vertical or horizontal position

• Sealing system with O-ring for optimum sealing and installation without flat gaskets.

| Technical specifications | |

|---|---|

| Construction | Wafer check valve |

| Size range | DN 40 ÷ 300 |

| Nominal pressure | 5 bar with water at 20 °C |

| Temperature range | 0 °C ÷ 60 °C |

| Coupling standards | Flanging system: DIN 2501 PN 10, EN ISO 1452,EN ISO 15493 |

| Reference standards | Construction criteria: EN ISO 16137 EN ISO 1452, EN ISO 15493 Test methods and requirements: ISO 9393 Installation criteria: DVS 2204, DVS 2221, UNI 11242 |

| Valve material | PVC-U |

| Seal material | EPDM |

Wafer Check Valve

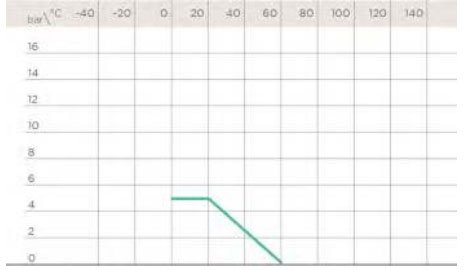

PRESSURE VARIATION ACCORDING TO TEMPERATURE

For water e non-hazardous fluids with regard to which the material is classified as CHEMICALLY RESIS-TANT. In other cases, a reduction of the nominal pressure PN is required (25 years with safety factor).

PRESSURE DROP GRAPH

KV 100 FLOW COEFFICIENT

| DN | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 |

|---|---|---|---|---|---|---|---|---|---|---|

| Kv100l/min | 370 | 900 | 1250 | 1867 | 2867 | 5700 | 8167 | 18800 | 25000 | 31900 |

The Kv 100 flow coefficient is the Q flow rate of litres per minute of water at a temperature of 20°C that will generate Δp= 1 bar pressure drop at a certain valve position. The Kv100 values shown in the table are calculated with the valve completely

open.

MINIMUM PRESSURE REQUIRED TO OPEN THE VALVE IN A VERTICAL FLOW

| DN | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 |

|---|---|---|---|---|---|---|---|---|---|---|

| bar | 0,002 | 0,003 | 0,003 | 0,003 | 0,003 | 0,003 | 0,005 | 0,005 | 0,008 | 0,008 |

MINIMUM VALVE SEALING PRESSURES

| DN | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 |

|---|---|---|---|---|---|---|---|---|---|---|

| bar | 0,3 | 0,3 | 0,3 | 0,2 | 0,2 | 0,2 | 0,2 | 0,2 | 0,2 | 0,2 |

TIGHTENING TORQUE

| DN | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 |

|---|---|---|---|---|---|---|---|---|---|---|

| Nm* | 8 | 10 | 10 | 10 | 0 | 15 | 20 | 38 | 45 | 50 |

*Tightening torques for nuts and bolts on couplings with backing rings. Values required to obtain the hydraulic test seal (1.5 x PN at 20°C) (new or lubricated nuts and bolts)

CROV

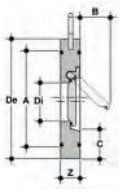

Wafer check valve in PVC-U/EPDM| d | DN | A | B | C | ISO/DIN | Di | OP | Z | g | *MOP(bar) | Code |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 50 | 40 | 72 | 25 | 28 | 95 | 22 | 0-5 | 16 | 160 | 6 | CROV050E |

| 63 | 50 | 86 | 37 | 29 | 109 | 32 | 0-5 | 20 | 260 | 6 | CROV063E |

| 75 | 65 | 105 | 50 | 31 | 129 | 40 | 0-5 | 20 | 330 | 6 | CROV075E |

| 90 | 80 | 119 | 61 | 32 | 144 | 54 | 0-5 | 20 | 400 | 6 | CROV090E |

| 110 | 100 | 146 | 77 | 31 | 164 | 70 | 0-5 | 22 | 560 | 6 | CROV110E |

| 140 | 125 | 173 | 94 | 35 | 195 | 92 | 0-5 | 23 | 760 | 6 | CROV140E |

| 160 | 150 | 197 | 100 | 40 | 220 | 105 | 0-5 | 25 | 1120 | 6 | CROV160E |

| 225 | 200 | 255 | 152 | 38 | 275 | 154 | 0-5 | 35 | 2130 | 6 | CROV225E |

| 280 | 250 | 312 | 180 | 41 | 330 | 192 | 0-5 | 40 | 3540 | 6 | CROV280E |

| 315 | 300 | 363 | 215 | 41 | 380 | 227 | 0-5 | 45 | 5350 | 6 | CROV315E |

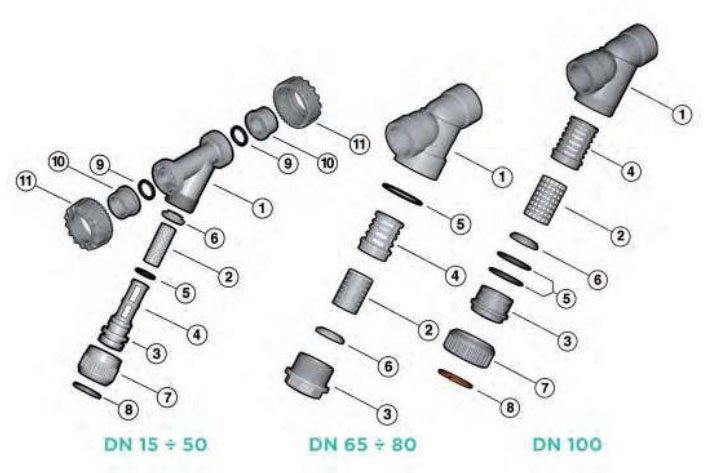

EXPLODED VIEW

- 1 Body (PVC-U – 1)

- 2 Strainer (PVC-U/STAINLESSsteel – 1)*

- 3 Bonnet (PVC-U – 1)

- 4 Strainer support (PVC-U – 1)

- 5 O-Ring (EPDM-FKM – 1)*A-B

- 5 C O-Ring (EPDM-FKM – 2)*

- 6 Washer (PVC-U – 1)

- 7 Union nut (PVC-U – 1)

- 8 Retaining ring (PVC-U – 1)

- 9 Socket seal O-Ring (EPDM-FKM- 2)*

- 10 End connector (PVC-U – 2)*

- 11 Union nut (PVC-U – 2)

The material of the component and the quantity supplied are indicated between brackets

GET THE LATEST PPH Wafer Check Valve PRICES ON YOUR EMAIL