PPH Solenoid Valve

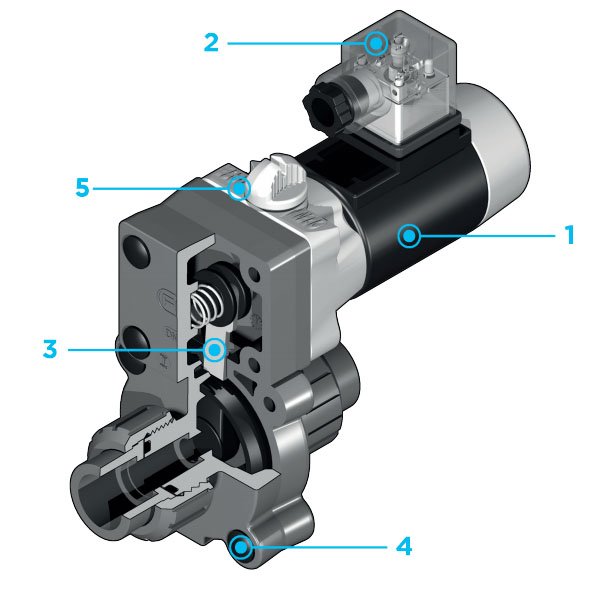

• 2-Way PVC-U body

• Installation flexibility and ease of maintenance: high-performance solenoid

electric actuator designed to exceed 5 million maintenance-free operating cycles

• Adjustable circular section coil with IP65 protection class.

• Integrated override with the possibility of being installed in 3 different positions.

• Lever shutter in EPDM or FKM and lever in stainless steel.

• DIN 43650 electrical connector supplied as standard: includes LED indicator light

and rectifier (in the case of an AC coil).

PPH Valves

Custom Product Manufacturing Available

If you are searching for customized product designs that meet your requirements, don’t worry. Petron Thermoplast also offers custom product manufacturing services to meet the unique needs of various industries. Work with our expert engineers to create custom designs suited for your application.

Get Quick Information

PPH Solenoid Valve

.

| Technical specifications – S1-S3 | |

| Construction | 2-way solenoid valve |

| Si range | S12: DN 4-6-8S22: DN 8-10-15 |

| Temperature range | 0 °C ÷ 50 °C |

| Coupling standards | Solvent welding: EN ISO 1452 EN ISO 493 ISO 727 DIN 8063 ASTM D2467 BS 4346-1 ISO 727-2. Can be coupled to pipes according to ISO 161/1 DIN 8062 ASTM D11785/76 BS 3506 BS 3505 Thread: ISO 228-1 DIN 2999 ASTM D 2467 (NPT) BS 21 BS 10226 ISO 7-1 |

| Valve material | PVC-U |

| Seal material | EPDM FKM |

(3.) Lever shutter in EPDM or FKM and lever in stainless steel. Suitable for use with aggressive fluids: no metal component

in contact with the fluid or the external environment; all the screws are covered by PE protection plugs.

(5.) Emergency override.

TYPE S12 2-WAY VALVE PERFORMANCE

| DN | 4 | 6 | 8 |

| PN | 6 | 4 | 2 |

| Kv(l/min)* | 6.7 | 12.1 | 15.3 |

TYPE S22 2-WAY VALVE PERFORMANCE

| DN | 8 | 10 | 15 |

| PN | 6 | 4 | 2 |

| Kv(l/min)* | 27.5 | 34.2 | 58.3 |

Q flow of litres per minute of water at a temperature of 20°C that will generate ∆p= 1 bar pressure drop

at a certain valve position.

The values shown in the table are calculated with the valve completely open.

TYPE S22 2-WAY VALVE PERFORMANCE

| DN | 8 | 10 | 15 |

| PN | 6 | 4 | 2 |

| Kv(l/min)* | 27.5 | 34.2 | 58.3 |

Q flow of litres per minute of water at a temperature of 20°C that will generate ∆p= 1 bar pressure drop

at a certain valve position.

The values shown in the table are calculated with the valve completely open.

GENERAL CHARACTERISTICS

| Functional characteristics | lever shutter |

| S12 and S22 2-way valve control functions | NC |

| Body material | PVC-U |

| Seal material | EPDM or FKM. |

| Maximum environmental temperature | 50° C |

| Maximum working fluid viscosity | 38 cSt |

| Service | 100% ED |

| Close time | ~ 20 ms |

| Open time | ~ 20 ms |

| Alternating current voltages | 24V – 110V* – 230V |

| Frequency | 50-60 Hz |

| Direct current voltages | 24 V |

| Voltage tolerance | ± 10% |

| S12 absorbed power | 10 W |

| S22 absorbed power | 20 W |

| Electrical protection | IP 65 |

| Electrical connection | DIN 43650 connector with LED (1) |

| Coil thermal class | F (155°C) |

| Installation | In any position |

| Coil rotation | over 360° |

*Voltage upon request

(1) Connector with internal electronic circuit specific to coil used

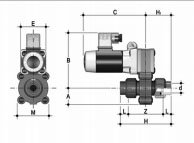

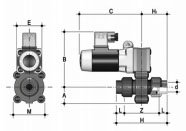

S12AV

2 way solenoid valve with BS female union ends for solvent welding.

Function: Normally closed

| d | DN | A | B | C | H | H1 | L | Z | E | M | g | EPDM Code | FKM Code |

| 1/4” | 4-6-8 | 24 | 100 | 103 | 92 | 46 | 16 | 60 | 42 | 52 | 400 | See code page | See code page |

| 3/8” | 4-6-8 | 24 | 100 | 103 | 98 | 49 | 19 | 60 | 42 | 52 | 400 | See code page | See code page |

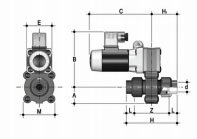

S22AV

2 way solenoid valve with ASTM female union ends for solvent welding.

Function: Normally closed

| d | DN | A | B | C | H | H1 | L | Z | E | M | g | EPDM Code | FKM Code |

| 3/8” | 8-10-15 | 34 | 115 | 130 | 109 | 55 | 19 | 71 | 54 | 67 | 1000 | See code page | See code page |

| 1/2” | 8-10-15 | 34 | 115 | 130 | 116 | 58 | 22 | 72 | 54 | 67 | 1000 | See code page | See code page |

S12LV

2 way solenoid valve with BS female union ends for solvent welding.

Function: Normally closed

| d | DN | A | B | C | H | H1 | L | Z | E | M | g | EPDM Code | FKM Code |

| 3/8′ | ‘ 4-6-8 | 24 | 100 | 103 | 88 | 44 | 14 | 60 | 42 | 52 | 400 | See code page | See code page |

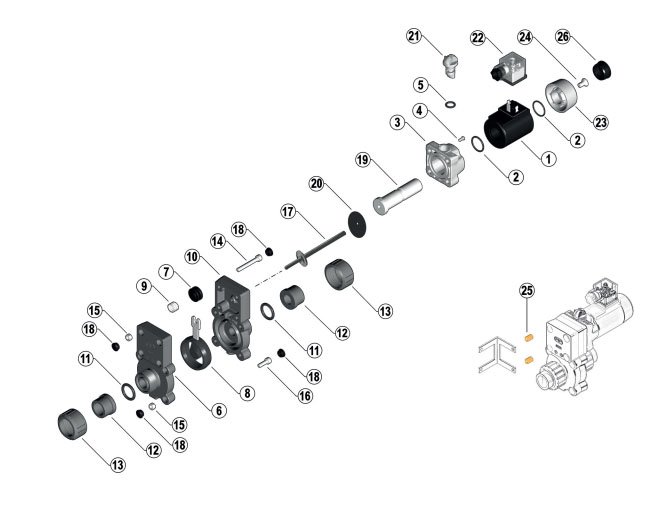

- 1 Coil (PA-GR – 1)*

- 2 O-Ring (EPDM – 2)*

- 3 Override housing (PP-GR – 1)

- 4 Screw (STAINLESS steel – 1)

- 5 O-Ring (EPDM – 1)*

- 6 Upper semi-body (PVC-U – 1)

- 7 Spring return end (PP-GR – 1)

- 8 Shutter (EPDM-FKM – 1)*

- 9 Spring return (stainless steel – 1)

- 10 Lower semi-body (PVC-U – 1)

- 11 O-Ring (EPDM – FKM – 2)*

- 12 End connector (PVC-U – 2)

- 13 Union nut (PVC-U – 2)*

- 14 Fixing screws (stainless steel – 4)

- 15 Fixing nuts (stainless steel – 8)

- 16 Fixing screws (stainless steel – 4)

- 17 Stem (STAINLESS steel – 1)

- 18 Protection plug (PE – 8)

- 19 Actuator (STAINLESS steel – 1)

- 20 Diaphragm seal (VMQ-1)

- 21 Override (PP-GR – 1)

- 22 Connector (1)*

- 23 Bonnet Coil (PP-GR – 1)

- 24 Bonnet fixing screws (stainless steel – 1)

- 25 Fixing nuts (Brass – 2)

- 26 Protection plug (PE – 1)

* Spare parts

The material the component is made of and the quantity supplied are shown in brackets

GET THE LATEST PPH Solenoid Valve PRICES ON YOUR EMAIL