DuPont™ Vespel® Polyimide

DuPontTM Vespel® Polyimide is a creep-resistant, highly high-temperature plastic that is frequently employed in high-heat situations where thermoplastic polymers lose their mechanical characteristics. Vespel® is a lightweight metal substitute that comes in a range of formulas, including unfilled grades as well as reduced friction and wears grades.

DuPontTM Vespel® Polyimide is capable of working at temperatures ranging from cryogenic to extremely hot. It possesses a low and constant thermal expansion coefficient, as well as excellent, creep properties, allowing DuPontTM Vespel® forms to be machined to tight dimensional tolerances.

DuPontTM Vespel® is a great choice for applications such as valve components where sealing is essential due to its ductility and exceptional creep and stress relaxation characteristics.

DuPont™ Vespel® Polyimide is capable of operating in a wide temperature range from cryogenic to extremely high temperatures. It has a low and consistent thermal expansion coefficient and outstanding creep characteristics, which allows parts made from DuPont™ Vespel® shapes to be machined to tight dimensional tolerances. The ductility and outstanding creep and stress relaxation behavior of DuPont™ Vespel® make it an excellent choice for applications such as valve components where sealing is required.

The Vespel® SP Family grades are available in a number of formulations including an unfilled grade (Vespel® SP-1) as well as filled grades with enhanced mechanical properties, dimensional stability, and friction and wear performance.

The Vespel® SCP Family grades are stronger and stiffer and have superior long-term thermal stability compared with the SP grades.

Is DuPont™ Vespel® right for your demanding application? Our plastics experts can answer your questions and discuss material options.

DuPont™ Vespel® Polyimide Properties and Options

EXPLORE DUPONT™ VESPEL® SP POLYIMIDE MATERIALS

DuPont™ Vespel® SP-1

DuPont™ Vespel® Polyimide SP-1 is unfilled and offers superior electrical and thermal insulation properties.

DuPont™ Vespel® SP-3

DuPont™ Vespel® Polyimide SP-3 for unlubricated sealing and low wear in vacuum or dry environments with low outgassing.

DuPont™ Vespel® SP-21

DuPont™ Vespel® Polyimide SP-21 is a graphite-enhanced grade with low-friction properties.

DuPont™ Vespel® SP-22

DuPont™ Vespel® Polyimide SP-22 is dimensionally stable and offers enhanced resistance to wear and friction.

DuPont™ Vespel® SP-211

DuPont™ Vespel® Polyimide SP-211 has a lower coefficient of friction than SP-21 without lubrication.

DuPont™ Vespel® SP-202

DuPont™ Vespel® Polyimide SP-202 conductive polymer eliminates static charge in high temperature substrate handling applications.

EXPLORE DUPONT™ VESPEL® SCP POLYIMIDE MATERIALS

DuPont™ Vespel® SCP-5000

DuPont™ Vespel® Polyimide SCP-5000 is unfilled with enhanced mechanical properties and thermal stability.

DuPont™ Vespel® SCP-5009

DuPont™ Vespel® Polyimide SCP-5009 is is graphite filled for high wear and friction applications.

DuPont™ Vespel® SCP-5050

DuPont™ Vespel® Polyimide SCP-5050 bearing and wear grade, for high temperature and wear resistance.

DuPont™ Vespel® SCP-50094

DuPont™ Vespel® Polyimide SCP-50094 for demanding applications that require high temperature and wear resistance.

DUPONT™ VESPEL® IS WIDELY USED FOR:

Semiconductor and material handling machinery

Chip test sockets

Wafer clamping rings

Valve seats and sealing applications

Spline couplings

High performance bearings and bushings

Locking fasteners for aerospace

Pivot bushings on unison ring

PERFORMANCE CHARACTERISTICS:

Long term performance at temperatures

up to 260°C (500°F)

Outstanding sealing characteristics when mated against metals

Excellent unlubricated bearing and wear properties (bearing grades)

Good electrical insulating properties

(unfilled grades)

COMMON BRANDS:

DuPont™ Vespel®

DuPont™ Vespel® for Aerospace Applications

DuPont™ Vespel® has a been specified for critical-service aerospace applications for many decades. The key properties of DuPont™ Vespel® for aerospace components include the material’s ability to maintain moderate modulus and have low stress relaxation throughout a broad temperature range. Filled grades of DuPont™ Vespel® are formulated to have enhanced friction and wear performance when sliding friction is required in service.

Aerospace applications include:

Locking elements for fasteners

Valve seats and seals

Thermal isolators

Bearings

Bushings

Splines

DuPont™ Vespel® for Spacecraft DuPont™

Vespel® has been widely used for spacecraft applications since the early days of space exploration. DuPont™ Vespel® is often specified for insulators, seals, bearings, bushings, rollers, and slide pads that require reliable performance in extreme conditions.

The key advantages of DuPont™ Vespel® for spacecraft applications include:

Grades available that have excellent friction and wear characteristics in vacuum

Maintains ductility and moderate modulus throughout a broad temperature range – from cryogenic to elevated temperatures

Excellent flammability characteristics

Good dimensional stability – low and consistent thermal expansion coefficient throughout a wide operating temperature range

Low outgassing

DuPont™ Vespel® for Semiconductor Machinery

DuPont™ Vespel® is used for a wide variety of semiconductor machinery applications including wafer handling, wafer processing, IC handling, and testing.

The key advantages of DuPont™ Vespel® for semiconductor manufacturing include:

Long wear life • Dimensional stability

Outstanding electrical properties

Chemical resistance • Easier to machine than ceramics

Able to operate reliably at temperatures up to 550 °F (or higher for short duration)

Clean operation, virtually no particulate shedding

Low outgassing

Semiconductor machinery applications include:

Spin chucks

Wafer clamping rings

Insulators • Bearings

Centering pins

Vacuum pads

Wafer guides

Vacuum tips

Die pickup collets •

Test sockets

DuPont™ Vespel® for Scientific Instrumentation

DuPont™ Vespel® is widely used for scientific instrumentation applications.

The key performance advantages of DuPont™ Vespel® for scientific equipment include:

Excellent sealing characteristics

Maintains ductility at cryogenic temperatures

Low outgassing

Gamma and electron beam radiation resistance

Wide operating temperature range

Grades available that have superior friction and wear performance

Low thermal conductivity

Dimensional stability Scientific instrumentation applications include:

Cryogenic thermal insulators

Bearings and bushings

Valve components

Ferrules

Electrical insulators

HPLC components

Components for accelerators

STANDARD SIZES

| SHEET | Dimensions: 12 in x 12 in – 48 in x 96 in |

| Thickness: 0.060 in – 4 in |

| ROD | Outside Diameter: 0.250 in – 6 in |

OPTIONS AVAILABLE

| COLOR | Sheet: Natural, White, Off White, Black, Beige, Dark Gray, Light Gray, RedRod: Natural, Black 0.250 in – 6 in |

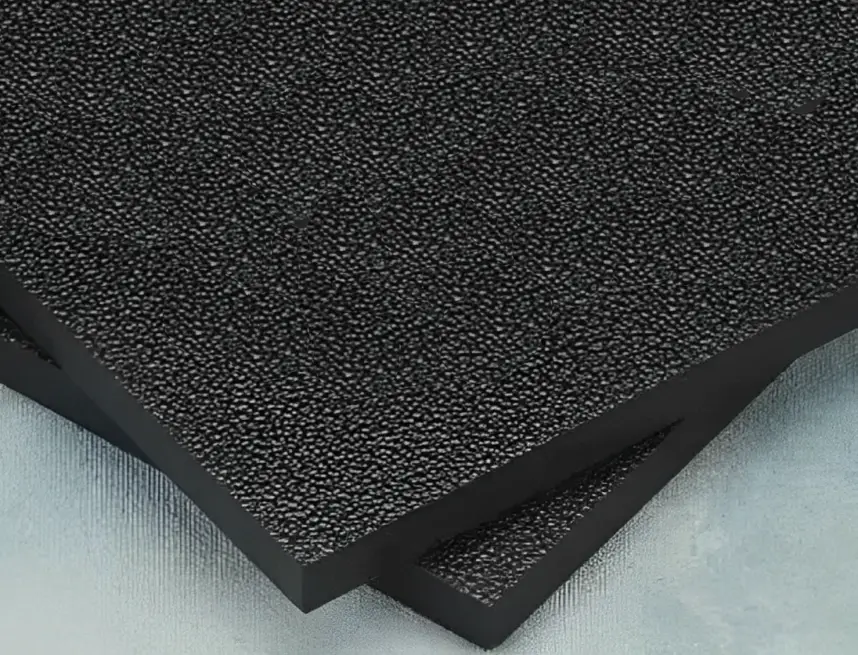

| TEXTURE, SURFACE, PATTERN | Level Haircell, Smooth / Smooth, Haircell 1 Side |

| GRADES | General Purpose, Fire-Rated, Machine Grade, UV Resistant, Scratch Resistant |

*Versus carbon steel, steady state, unlubricated, in air, thrust bearing. **PV limits for any given material vary with various combinations of pressure and velocity as well as other conditions.

Explore the physical, mechanical, thermal, electrical and optical properties of DuPont™ Vespel® polyimide.

Sort, compare and find suitable plastic materials for your application using our interactive properties table.

The information provided here is provided free of charge, is based on technical data that DuPont considers reliable, and represents specific values that fall within the general category of assets. This information pertains only to the specified specific material and may not be valid for such material used in combination with other materials or other processes. It is intended for use by persons with technical skills at their own discretion and risk. This information should not be used to establish specification limits nor should it be used only as a basis for design. Precautions are provided with the understanding that its users will satisfy themselves that their particular terms of use do not pose a health or safety hazard and comply with applicable law. Since the terms of use and disposal of the product are beyond our control, we assume no warranty, express or implied, and no liability in relation to any use of this information. As with any product, evaluation is required under end-use conditions prior to specification. Nothing here is to be taken as a recommendation to infringe a license or patent to operate.

Caution: Do not use DuPont Materials in medical applications involving implantation in the human body or contact with internal body fluids or tissues unless the Materials have been provided under a written contract from DuPont that DuPont regarding medical applications Conforms to policy and expressly accepts consideration of use.

DuPont’s sole warranty is that our products will effectively meet our standard sales specifications at the time of shipment. Your exclusive remedy for breach of such warranty is limited to a refund of the purchase price or replacement of a product other than warranted. To the fullest extent permitted by applicable law, DuPont specifically disclaims any other express or implied warranties of fitness for a particular purpose, merchantability, or non-infringement. DuPont disclaims liability for any special, incidental, or consequential damages.

DuPont™, the DuPont Oval logo, and all trademarks and service marks marked with ™, or ® are owned by DuPont de Nemours, Inc. are owned by its affiliates, unless otherwise noted.

© 2021 DuPont. All rights reserved.