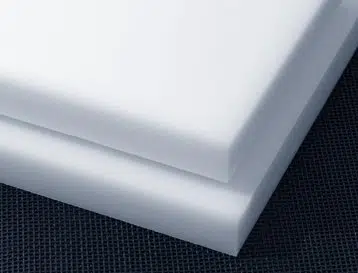

LDPE (Low Density Polyethylene)

Low density polyethylene (LDPE) is a soft, flexible, and lightweight plastic. Low-temperature flexibility, toughness, and corrosion resistance are all characteristics of LDPE.

It is not suitable for applications requiring rigidity, high-temperature resistance, or structural strength. It’s a popular material for orthotics and prosthetics. LDPE (Low Density Polythylene) is chemically and impacts resistant, as well as being simple to manufacture and shape.

LDPE, on the other hand, has a lower “density” than HDPE, as the name implies. That simply indicates it has a lower mass to volume ratio. It’s light and powerful at the same time. It can withstand a lot of punishment. It has a long lifespan and is resistant to the elements.

LDPE IS WIDELY USED FOR:

- Orthotics

- Prosthetics

PERFORMANCE CHARACTERISTICS:

- Soft and pliable

- Easy to weld and heat seal

- Good chemical resistance

- Low moisture absorption

COMMON BRANDS:

- Orthoform®

- C-TEK® MODStiff™

- Densetec

- TECAFINE®

STANDARD SIZES

| INDUSTRIAL SHEET | Dimensions: 48 in x 96 in |

| Thickness: 0.030 in – 0.500 in |

| SHEET FOR O & P | Dimensions: 12 in x 12 in – 48 in x 96 in |

| Thickness: 0.030 in – 0.500 in |

| C-TEK® MODSTIFF | Dimensions: 24 in x 48 in – 48 in x 96 in |

| Thickness: 0.125 in – 0.156 in |

OPTIONS AVAILABLE

| COLOR | Sheet: Natural, BlackRod: Natural |

| TEXTURE, SURFACE, PATTERN | Smooth |

Length, width, thickness, and diameter tolerances vary by size, by manufacturer, brand, and grade. Custom sizes available upon request.

LDPE Properties and Material Options

LDPE Sheet Stress Relieved– offers improved machinability and dimensional stability over extruded LDPE.

FDA Compliant LDPE– LDPE is available in FDA compliant grades.

LDPE Sheet for O&P– Low Density Polyethylene is more flexible than HDPE, polypro, or copoly PP, making it an excellent choice for pediatric AFOs, some splints, and flexible socket interfaces.

C-TEK® MODStiff™– Offers a level of stiffness between modified polyethylene and copoly. This unique material is used in applications where modified polyethylene is not stiff enough and copoly is too stiff. The ability to downgauge material thickness provides the opportunity to lighten an orthoses. Watch video to learn more.

Modified LDPE Sheet for O&P– Modified polyethylene is slightly stiffer than LDPE, but more flexible than HDPE, polypro, or copoly PP. It is used for applications where flexibility and light support are required.

Tech Tip– LDPE materials can be difficult to decorate with transfer paper.

TYPICAL PROPERTIES OF LDPE

| UNITS | ASTM TEST | LDPE | |

|---|---|---|---|

| Tensile strength | psi | D638 | 1,400 |

| Flexural modulus | psi | D790 | 30,000 |

| Izod impact (notched) | ft-lbs/in of notch | D256 | no break |

| Heat deflection temperature @ 264 psi | °F | D648 | 122 |

| Maximum continuous service temperature in air | °F | – | |

| Water absorption (immersion 24 hours) | % | D570 | 0.10 |

| Coefficient of linear thermal expansion | in/in/°Fx10-5 | D696 | – |

Please ask your Petron Thermoplast representative for more specific information about an individual brand.

POPULAR PLASTIC MATERIAL COMPARISONS:

HDPE vs. LDPE — One is more rigid while the other is more flexible, but which is right for your specific application?

Explore the physical, mechanical, thermal, electrical, and optical properties of LDPE.

Sort, compare, and find the plastic material suited for your application using our interactive properties table.

Please ask your Petron Thermoplast representative for more specific information about an individual brand.

Explore the physical, mechanical, thermal, electrical, and optical properties of acetal plastic materials.

Sort, compare, and find the acetal plastic material suited for your application using our interactive properties table.