PPSU Materials (Polyphenylsulfone)

PPSU Materials (Polyphenylsulfone) is a new material for making baby bottles. PPSU is a polyether plastic composed of Bisphenol S (BPS) and 4, 4′-Dihydroxybiphenyl (DHBP) both of which have modest endocrine effects in vitro.

These are moldable polymers that are often used in fast prototyping and Direct Digital Manufacturing (DDM) applications. Heat and chemical resistance make Polyphenylsulfones is an ideal for automotive, aerospace and the plumbing applications. Petron Thermoplast is the best manufacturer of PSU Materials with 100% high-quality made Engineering Plastic materials.

The PPS materials, known as polyphenylsulfone (PPSU), has several properties that make it an increasingly popular metal-replacement material in medical applications.

The usual operating temperatures of approximately +170 °C – and its resistance to chemicals and harsh disinfectants commonly used in hospitals. Polyphenylsulfone plastic has no melting point, indicating that PPSU Material is amorphous, and has a tensile strength of up to 8000 pounds per square inch.

PPSU IS WIDELY USED FOR:

- Aircraft interior parts

- Aircraft bezels

- Instrument handles

- Medical instrument components

- Sterilization trays

- Implant trials

PERFORMANCE CHARACTERISTICS:

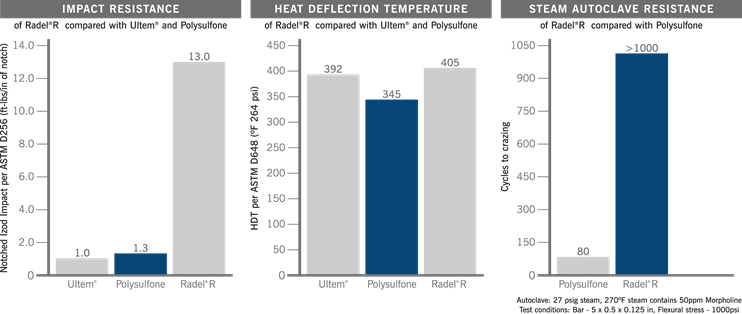

- Extremely high impact resistance

- Resistant to hydrolysis when exposed

- to hot water and steam

- Can withstand repeated sterilization

- cycles in a steam autoclave

- Thermoforms well

COMMON BRANDS:

- Radel® R

STANDARD SIZES

| SHEET | Dimensions: 24 in x 48 in |

| Thickness: 0.500 in – 2 in |

| ROD | Outside Diameter: 0.375 in – 3.500 in |

OPTIONS AVAILABLE

| COLOR | Black |

Length, width, thickness, and diameter tolerances vary by size, by manufacturer, brand, and grade. Custom sizes available upon request.

PPSU Properties and Material Options

Radel® R-5500– is a general purpose extrusion grade of polyphenylsulfone (PPSU) offering exceptional hydrolytic stability and better toughness than most commercially available high temperature polymers.

Tech Tip– PPSU is often used instead of polysulfone or Ultem® for medical applications when superior toughness or extended service life with repeated autoclave cycles is desired.

TYPICAL PROPERTIES OF PPSU

| UNITS | ASTM TEST | RADEL® R | |

|---|---|---|---|

| Tensile strength | psi | D638 | 10,100 |

| Flexural modulus | psi | D790 | 350,000 |

| Izod impact (notched) | ft-lbs/in of notch | D256 | 13.0 |

| Heat deflection temperature @ 264 psi | °F | D648 | 405 |

| Maximum continuous service temperature in air | °F | 392 | |

| Water absorption (immersion 24 hours) | % | D570 | 0.37 |

| Coefficient of linear thermal expansion | in/in/°Fx10-5 | D696 | 3.1 |

Please ask your Petron Thermoplast is the representative for more specific information about a single brand.

Explore the physical, mechanical, thermal, electrical and optical properties of PPSUs.

Sort, compare and find suitable plastic materials for your application using our interactive properties table.