Wastewater Treatment with PVDF Ball Valve

What is the significance of plastic PVDF ball valves in wastewater treatment plants? The conditions at these factories are quite acidic. Large vessels and piping systems transport dirty water and chemicals that are exceedingly corrosive and abrasive. This is why it’s so important to make the right material choices. It maintains the cost-effectiveness and efficiency of wastewater treatment systems.

Click here to know more about technical specifications.

Defining PVDF:

PVDF, or Polyvinylidene difluoride, is a fluorinated, semi-crystalline technopolymer that contains 59 percent fluorine by weight. This material is created by polymerizing vinylidene fluoride.

It has excellent mechanical, physical, and chemical resistance and excellent thermal stability up to 140 degrees Celsius.

Corrosive media damage to pipes, valves, and fittings can have a significant financial impact on wastewater and water treatment plants. As a result, experienced engineers and procurement personnel turn to cost-effective and dependable materials, including UPVC, CPVC, PP, and PVDF.

These sophisticated plastics have a lot of advantages:

- Corrosion is eliminated.

- When compared to their metallic equivalents, they have a lower life-cycle cost.

- Mechanical strength is exceptional.

- Installation and maintenance times are reduced due to the lightweight design.

PROPERTIES AND ITS BENEFITS:

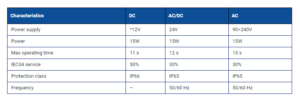

PVDF BALL VALVE TECHNICAL SPECIFICATIONS

Agriculture and irrigation use plastic valves.

The majority of irrigation components, including filters, pipelines, meters, and valves, are metal. However, there has been a growing tendency toward employing thermoplastics in recent years. Why would a designer of an irrigation system choose plastic valves over metal components that have been proven to be effective? Is it merely a matter of cost-cutting, or is there more to it?

Chemical resistance: Plastic valves do not rust when exposed to saline or acidic water, one of its main advantages. This is especially critical for systems that frequently use water to apply fertilizers and pesticides—standard metals, such as ductile iron, and rust in acidic environments. On the other hand, Plastics can withstand extreme pH changes and are chemically inert.

Plastics are, without a doubt, the most cost-effective material when it comes to cost. Metal is more expensive in terms of the raw material and the manufacturing process. Plastics are also less expensive to transport due to their lower weight.

Installation and maintenance are easier with plastic valves since they are lightweight and easier to handle. They are less prone to silt build-up and require little maintenance due to their smooth internal surface and lack of corrosion.

SUPPLIER OF PVDF DUAL BLOCK 2-WAY BALL VALVE

The PVDF Dual Block 2 Way Ball Valve Series from Petron Thermoplast is the best and most heavy-duty ball valve quality for the water and wastewater sectors and the best heavy-duty ball valve series for the agricultural industries.

We have a PVDF ball valve series called the Dual Block Series. A Dual Block 2-Way Ball Valve uses two seating surfaces to lock off pressure from both ends of a PVDF Dual Block 2 – Way Ball Valve.

Depending on your process and demands and industrial water application requirements, you can choose from a range of setups. When selecting a valve, the fluid properties, pressure, and temperature must be considered. On the other hand, Valve’s intended function may be the most important aspect.

The PVDF Dual Block 2-Way Ball Valve technology allows the P2 Valve to shine in operational settings when vibration or thermal expansion may undermine the standard’s performance. The system is simple to set up and requires no special tools. A proprietary union-nut locking system prevents Back-off in demanding service circumstances.

PVDF Ball Valve Operation:

The PVDF ball valve has an on/off function. In the open position, one hub interfaces the bay and outlet ports of the body through the ball’s focus point. When the passage through the ball is similar to inside the width of the line, the stream is straight, and there is a minor pressing factor drop. The ball valve is useful for disengaging the flow in fluid handling frameworks. The Valve is available with a PVDF body, EPDM or FPM O-Rings, and a PTFE ball. The materials chosen will be determined by the type of fluid handled by the framework and the working temperature. For more information, see the graphs of substance obstruction and pressing factor/temperature. A built-in instrument in the valve handle allows quick changes to the string seal transporter and ball force.

PETRON THERMOPLAST HAVE PVDF BALL VALVE WITH PVDF ELECTRIC ACTUATOR/PNEUMATIC ACTUATOR VALVES SOLUTION FOR CHEMICALS HANDLING LINE

- Patented SEAT STOP® ball seat carrier system allows for micro-adjustment of ball seats and minimization of axial force effects

- Easy radical disassembly allows for quick replacement of O-rings and ball seats without the use of tools

- Radial dismounting valve body (True Union) with built-in actuation bores for PVC-U, PVC-C, and PP-H injection molding. Test requirements that comply with ISO 9393

- Integrated bracket for valve anchoring • Possibility of installing pneumatic and electric actuators thanks to the robust anchor tower for easy and quick automation using the Power Quick module

- High surface finish stem with double O-Ring and double connection key to the ball, equipped with visual ball position indicator for correct handle installation.

FUNCTIONAL CHARACTERISTICS

PVDF ball Valve Have a Lot of Benefits

PVDF Valves’ inherent properties increased solution options for food and beverage processing businesses seeking to maximize efficiencies, such as brittleness, chemical resistance, and abrasion resistance.

FIP PVDF Ball Valve

- Weld and flanged joint connection systems

- The SEAT STOP ball carrier system is a patented device that allows you to micro-adjust ball seats and reduces the axial force effect.

- Without tools, radial disassembly allows for rapid replacement of O-rings and ball seats.

- Full bore floating ball with a high surface gloss

- Valve anchoring bracket integrated

- The Easytorque adjustment kit can be used to modify the ball seat carriers.

- Possibility of having a handle with an integrated LSQT limit micro switch, which may be retrofitted into existing installations.

General Characteristics

Excellent Chemical Resistance: When transporting highly aggressive chemicals, Solef resin, a vinylidene fluoride polymer, ensures excellent corrosion and abrasion resistance. PVDF is inert to most inorganic acids and bases, organic acids, aromatic and aliphatic hydrocarbons, alcohol, and halogenated solvents.

Excellent thermal stability: PVDF maintains its properties at temperatures ranging from -40 to +140 degrees Celsius. PVDF pipes are ideal for applications that require high working temperatures, low fluid contamination, and strong resistance to aging caused by atmospheric agents and UV radiation.

PVDF Ball Valve has been used in pipe and pumping applications and is available in sheets, films, tubing, plate, and as an insulator in a high-quality wire. Lithium-ion batteries are widely used in the semiconductor, chemical, medical, and defense industries.

We have these PVDF ball valves limited in our stocks.