Introduction

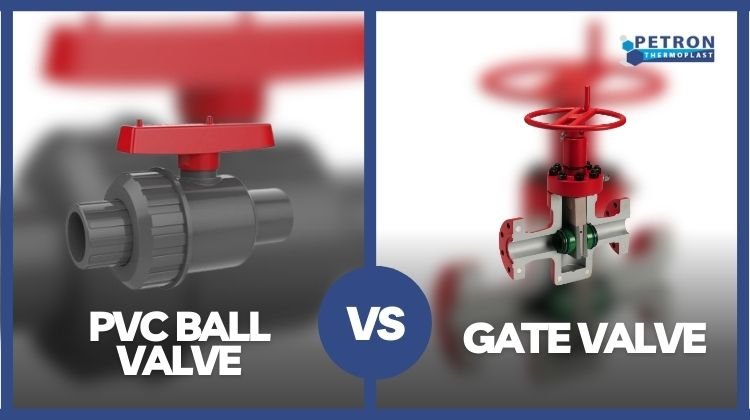

When it comes to controlling the flow of liquids or gases in plumbing systems, valves play a crucial role. Two common types of valves used in various applications are PVC ball valves and gate valves. Understanding the differences between these two valve types is essential for making informed decisions about their selection and installation. In this article, we will explore the Differences Between Pvc Ball Valves and Gate Valves, highlighting their unique features and applications.

What is Pvc Ball Valve?

A PVC ball valve is a type of valve made from polyvinyl chloride (PVC), a durable and corrosion-resistant plastic material. It is designed to control the flow of fluids, typically liquids or gases, by utilizing a spherical ball with a hole or port in the center. The ball within the valve can be rotated by a handle or lever, allowing for precise control over the flow rate. When the ball is aligned with the valve body, the fluid can pass through freely. However, when the ball is rotated to a perpendicular position, it blocks the flow, effectively shutting off the valve. PVC ball valves are commonly used in various applications such as plumbing, irrigation systems, industrial processes, and water treatment systems, among others, due to their affordability, chemical resistance, and ease of installation.

Types of Pvc Ball Valve

There are several types of PVC ball valves available, each with its own specific features and applications. Here are some common types:

- Standard PVC Ball Valve: This is the most basic type of PVC ball valve. It features a simple design with a PVC body, a ball with a hole in the center, and a handle or lever for rotation. It is suitable for general applications and offers reliable flow control.

- True Union PVC Ball Valve: This type of valve is designed with a union connection, allowing for easy installation and removal without cutting the pipe. It consists of two halves connected by a union nut, making it convenient for maintenance and repairs.

- Three-Way PVC Ball Valve: A three-way PVC ball valve has an additional port, allowing for the diversion or mixing of fluids. It provides flexibility in controlling flow between multiple directions or combining two streams into one.

- Compact PVC Ball Valve: Compact ball valves are smaller in size and have a reduced footprint, making them suitable for applications where space is limited. They offer the same functionality as standard ball valves but in a more compact design.

- PVC Ball Valve with Actuator: These valves are equipped with an actuator, which allows for automated control of the valve. The actuator can be electrically or pneumatically operated, providing remote control and integration into automated systems.

- PVC Check Valve with Ball: This type of valve combines the functionality of a ball valve with a check valve. It allows fluid flow in one direction and prevents backflow in the opposite direction, ensuring one-way flow control.

What is a Gate Valve?

A gate valve is a type of valve that controls the flow of fluids by using a sliding gate or wedge mechanism. It is named after the gate-like component that moves up and down to control the opening and closing of the valve. Gate valves are typically used in fully open or fully closed positions and are not designed for precise flow control.

Types of Types of Gate Valves

There are several types of gate valves, each designed for specific applications and operating conditions. Here are some common types of gate valves:

- Wedge Gate Valve: This is the most common type of gate valve and is characterized by a solid wedge-shaped gate that moves up and down to control the flow. Wedge gate valves can be further classified into three types:

- Solid Wedge Gate Valve: The gate has a solid, unsplit wedge design.

- Flexible Wedge Gate Valve: The gate has a split wedge design with some flexibility to accommodate changes in the valve seat and ensure a tight seal.

- Split Wedge Gate Valve: The gate has two separate halves, allowing more flexibility and improved sealing.

- Parallel Gate Valve: In parallel gate valves, the gate moves parallel to the direction of flow. This type of gate valve is often used in applications that require a tight seal and low pressure drop.

- Knife Gate Valve: Knife gate valves have a sharp-edged gate that cuts through thick and viscous fluids. They are commonly used in applications involving slurries, powders, and wastewater treatment.

- Slab Gate Valve: Slab gate valves are mainly used in the oil and gas industry for upstream applications. They feature a flat, slab-like gate that provides a tight seal and is resistant to pressure variations.

- Through Conduit Gate Valve: These gate valves have a full-bore design, meaning the opening through the valve has the same diameter as the pipeline. They are often used in pipelines that transport large volumes of fluids.

- Expanding Gate Valve: Expanding gate valves have a gate that expands and contracts to provide a tight seal. They are commonly used in high-pressure and high-temperature applications.

Differences Between Pvc Ball Valves and Gate Valves

The primary Differences Between Pvc Ball Valves and Gate Valves lies in the structural characteristics and marking methods of ball valves and gate valves. Gate valves operate by elevating a round or rectangular gate to clear the fluid’s pathway, whereas ball valves utilize a stem and a horizontally rotating ball.

1. Structure and Working Principle

1.1 PVC Ball Valves

PVC ball valves are compact and straightforward in design. They consist of a hollow, perforated ball within a PVC housing. The ball has a hole through the center, which allows the fluid to flow when aligned with the pipe. A handle attached to the ball allows for easy rotation, turning the valve on or off. The sealing mechanism of PVC ball valves is achieved by the ball pressing against the seat, creating a watertight seal.

1.2 Gate Valves

Gate valves are bulkier and more complex in construction compared to PVC ball valves. They comprise a metal gate or disc that moves up and down to control the flow. When the gate is lifted, it allows full fluid passage, while lowering the gate restricts or stops the flow. Gate valves utilize a multi-turn handle or wheel to operate, enabling precise flow control.

2. Flow Control Capabilities

2.1 PVC Ball Valves

PVC ball valves are primarily designed for on/off applications, making them ideal for situations where flow control is not critical. The ball inside the valve allows for easy and quick operation, providing instant shut-off when required. However, due to their design, PVC ball valves may not offer precise flow control in applications where throttling is necessary.

2.2 Gate Valves

Gate valves are specifically designed for precise flow control. The rising and lowering of the gate enable gradual flow adjustments, allowing for finer control of fluid volumes. This characteristic makes gate valves suitable for applications where accurate regulation of flow rates is crucial, such as in industrial processes or large-scale plumbing systems.

3. Pressure and Temperature Handling

3.1 PVC Ball Valves

PVC ball valves are typically suitable for low-pressure applications. They can handle moderate temperatures, but they have limitations when exposed to extreme temperature conditions. PVC materials may become brittle under very low temperatures or deform under high temperatures, affecting their overall performance.

3.2 Gate Valves

Gate valves are known for their robustness and ability to handle high-pressure and high-temperature conditions. The metal components used in gate valves provide excellent durability and resistance to extreme temperatures. These valves are often used in industrial settings where they can withstand demanding operating conditions.

4. Installation Flexibility

4.1 PVC Ball Valves

PVC ball valves are lightweight and compact, making them easy to handle and install. They are commonly used in residential and light commercial plumbing systems, as well as irrigation systems. The compact design also allows for convenient replacement or repair, if needed.

4.2 Gate Valves

Gate valves are bulkier and require more space for installation. They are typically used in applications where a large volume of fluid needs to be controlled, such as water treatment plants, power plants, and industrial processes. Due to their size and weight, gate valves may require additional support during installation.

5. Cost Considerations

5.1 PVC Ball Valves

PVC ball valves are generally more affordable compared to gate valves. Their simpler design and use of PVC materials contribute to their cost-effectiveness, making them a popular choice for many plumbing applications.

5.2 Gate Valves

Gate valves tend to be more expensive than UPVC ball valves due to their construction, use of metal components, and higher pressure and temperature handling capabilities. The cost of gate valves increases with the valve size, making them more suitable for industrial or commercial applications with specific requirements.

Conclusion

In summary, PVC ball valves and gate valves have distinct differences in terms of structure, flow control capabilities, pressure and temperature handling, installation flexibility, and cost considerations. PVC ball valves are compact, suitable for on/off applications, and cost-effective, while gate valves offer precise flow control, robustness, and suitability for high-pressure and high-temperature conditions. By understanding these differences, you can choose the right valve type for your specific needs, ensuring optimal performance and efficiency in your plumbing systems.

You may also like – Gear Manufacturer | UHMW Plastic | PEEK Parts

Pingback: พรมปูพื้นรถยนต์

Pingback: Howto-sbobet เว็บรวมเทคนิคแทงบอลขั้นเทพ ปิดแล้ว

Pingback: fenix168

Pingback: live cams

Pingback: สล็อตเว็บตรง โบนัสแตกโหด

Pingback: B1AU4IQ

Pingback: LSM99AI สล็อตเว็บตรงชั้นนำ