Introduction

Different Types of Valve used in Piping. This article delves into the categorization of valves and their respective roles. To kick things off, let’s begin with a definition of valves.

What is Valve?

You might already know this, but it’s okay to remind ourselves.

A valve is like a special tool that helps manage how liquids move. It can open, close, or slow down the liquid. If that sounds tricky, think of it as a machine that helps control how liquids move and how hard they push. So, in simple words, a valve is all about controlling the way liquids flow and how strong they flow.

Types of Valves | Different Types of Valve used in Piping

In pipes, we use different kinds of valves based on what we need. These valves can cost a lot, like 20% to 30% of all the money spent on the pipes. Also, the price of a valve can be very different, even twice as much, depending on its type and size. This means that if you pick a ball valve instead of a butterfly valve for the same job, it could cost you more money. So, it’s really important to choose the right valves to make sure process plants work well and don’t cost too much.

- Ball Valve

- Gate Valve

- Globe Valve

- Check Valve

- Plug valve

- Pinch Valve

- Needle Valve

- Butterfly Valve

- Pressure Relief Valve

“Let’s find out about each one of them.”

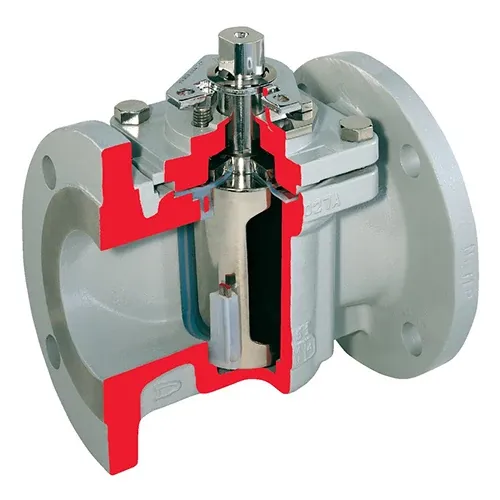

Ball Valve

A ball valve is like a simple switch for controlling the flow of liquids. It works by turning a round ball inside to start or stop the flow. You only need to turn it a little bit to make it work. This type of valve is smaller and lighter compared to another kind called a gate valve.

You can see different types of ball valves:

- 3-Way Ball Valve

- Floating Ball Valve

- Trunnion Mounted Ball Valve

- Top entry

- Side entry or split body

- Three-piece body

Gate Valve

A gate valve is a very common thing in factories. It’s like a door for liquids. It can either let the liquid go through or block it completely. We use gate valves for lots of liquids like air, fuel, water, and more. They’re good at stopping the flow of liquid when we need to.

Different types of Gate Valves:

- Solid Wedge Gate Valve

- Flexible Wedge Gate Valve

- Split Wedge or Parallel Disks Gate Valve

- OS & Y Gate Valve or Rising Stem Valve

- Non-rising Stem Gate Valve or Insider Screw Valve

Globe Valve

A Globe valve is like a switch for liquids. It can turn the flow on, off, or control it. People use Globe Valves in places where they need to control how much liquid flows, and they also want to make sure there are no leaks. Globe valves are better at stopping the flow of liquid compared to gate valves, but they are a bit more expensive.

Different types of Globe Valves:

- Z types

- Y types

- Angle Types

Check Valve

A check valve stops water from going the wrong way in pipes. When water goes in the right direction, it opens the valve. If it tries to go back, the valve closes.

Different check valves:

- Swing Type

- Lift Type

- Dual Plate Type

- Stop Check Valve

Plug Valve

A plug valve is like a twisty valve that you can turn a little to stop or start the water or whatever is flowing. It has a plug inside that looks like a cone or a cylinder, and this plug has a hole for the stuff to go through. Plug valves are used to completely stop or start the flow of things, and they don’t let anything leak through when they’re closed. These valves can be used in places with very high pressure and heat, even in a vacuum.

Different kinds of plug valves:

- Ones with a square hole

- Ones with a round hole

- Ones with a diamond-shaped hole

- Plug valves that need lubrication

- Plug valves that don’t need lubrication

- Plug valves with many holes for different uses.

Pinch Valve

A pinch valve, sometimes called a clamp valve, is like a door for liquids. It can open, close, or adjust how much liquid goes through. It works using a rubber tube, which is like a straw, and a pinching device to control the liquid. This type of valve is great for handling thick liquids, liquids with chunks in them, and systems that move solid stuff using air.

Needle Valve

Needle valves look a lot like globe valves, but they have a pointy needle-shaped part. These valves are made to control the flow of liquid very precisely in small pipes. They’re called “needle valves” because of their sharp, pointy disk and seat that fit together.

Butterfly Valve

A butterfly valve is like a spinning door that can stop, control, or start the flow of things. It’s small and round, which makes it great for big valve jobs because it doesn’t take up much space compared to other valves.

Different types of butterfly valves:

- Butterfly valves with flanges

- Butterfly valves that are like wafers

- Butterfly valves with lugs

- Butterfly valves that are butt welded

- Butterfly valves with zero offset

- Butterfly valves with double offset

- Butterfly valves with triple offset

Pressure Relief Valve

A pressure safety valve is like a guardian for machines and pipes. When they feel too much pressure or when there’s not enough air inside, these valves step in. They let out some pressure or air when it reaches a certain limit.

Different types of Pressure Relief Valves:

- Reclosing-type pressure relief devices

- Non-reclosing type pressure relief devices

- Safety Relief Valves

- Pressure Relief Valve

- Vacuum Relief Valve

- Pressure Vacuum Relief Valve

Valves Types Based on Functions

The valve serves various functions within the piping system. Such as

- Stopping and starting a fluid flow. Depending on whether a valve is open or closed, it lets pass the process fluid or halts the fluid.

- Throttling the fluid flow. Some of the valves let you throttle the fluid depending open % of the total opening. Lesser the opening, higher the throttling and otherwise.

- Controlling the direction of fluid flow. The multiport valve lets you decide the way fluid will go.

- Regulating a flow or pressure within the piping system. Some of the automatic control valves maintain the flow and pressure within the system by adjusting opening and closing.

- Relieve pressure or vacuum from the piping system and equipment. Pressure and vacuum relief valves safeguard the processing system from overpressure and during vacuum conditions.

Different types of valves serve these functions. These valves can be classified or categorized based on;

- Function

- End connection

- How it operates

- Types of Actuator it used.

Classification of Valves Based on End Connections

Valve ends come in different types based on how they connect to pipes:

- Screwed or Threaded Ends: These valves have threads that match those on the pipe. They are used for small valves in instruments or as sample points.

- Flanged Ends: Most valves used in pipes have flanged ends, which means they have flat, circular parts that are bolted onto the pipes.

- Butt-Welded Ends: These valves are used in places with very high pressure and heat.

- Socket Welded Ends: These valves are used in low-pressure situations.

- Check Valves and Butterfly Valves: These can have wafer and lug end construction, which is helpful when there isn’t much space.

So, valves can have different ends depending on where and how they’re used.

Classification of Valves Based on The Way it Open and Closed

Here’s a simple table that classifies valves based on the way they open and close:

| Valve Type | Opening and Closing Mechanism |

|---|---|

| Gate Valve | Raised and lowered gate or wedge |

| Globe Valve | Up and down movement of a disc |

| Ball Valve | Rotating a ball with a hole |

| Butterfly Valve | Rotating a disc or vane |

| Check Valve | Flow allows one-way movement |

| Plug Valve | Rotating a plug or cylinder |

| Diaphragm Valve | Squeezing a flexible diaphragm |

| Pinch Valve | Pinching a flexible tube |

| Needle Valve | Fine adjustment with a needle |

| Pressure Relief Valve | Automatically opens at preset pressure |

| Safety Valve | Automatically opens to release excess pressure |

| Solenoid Valve | Electrically controlled, typically on/off |

| Piston Valve | Sliding piston controls flow |

| Spool Valve | Shifting a spool to direct flow |

Classification of Valves Based on Types of Actuator it Used

Here’s a simple table to classify valves based on the types of actuators they use:

| Actuator Type | Valve Classification |

|---|---|

| Manual | – Gate Valve |

| – Globe Valve | |

| – Ball Valve | |

| – Check Valve | |

| – Butterfly Valve | |

| Electric | – Electric Gate Valve |

| – Electric Globe Valve | |

| – Electric Ball Valve | |

| – Electric Butterfly Valve | |

| Pneumatic | – Pneumatic Gate Valve |

| – Pneumatic Globe Valve | |

| – Pneumatic Ball Valve | |

| – Pneumatic Butterfly Valve | |

| Hydraulic | – Hydraulic Gate Valve |

| – Hydraulic Globe Valve | |

| – Hydraulic Ball Valve | |

| – Hydraulic Butterfly Valve |

You may also like – Polycarbonate Sheet | Acrylic Plastic Sheet | Custom Plastic Injection Molding