Acrylic Materials of the Plastic

Acrylic Materials of the Plastic is a strong, rigid, and optically clear transparent plastic with excellent strength and stiffness. Acrylic transparent plastic sheets are very simple to manufacture, adheres well to adhesives and solvents, and Thermoforms readily. It outperforms several other transparent polymers when it comes to weathering.

Design Acrylic sheets has glass-like characteristics such as clarity, brightness, and transparency, yet it is half the weight of glass and has several times the impact resistance. Acrylic plastics provide exceptional adaptability, durability, and aesthetic characteristics.

In everything from sturdy signage and skylights to eye-catching retail store fixtures, displays, and shelves. Acrylic Materials of the Plastic is a fantastic material for applications that require transparency but don’t require a lot of impact resistance.

ACRYLIC IS WIDELY USED FOR:

Indoor and outdoor signs

POP displays and exhibits

Architectural glazing, skylights

LED diffusing lighting panels

Transportation applications

Brochure holders

Shelves and retail fixtures

Transparent manifolds

Frames and display cases

PERFORMANCE CHARACTERISTICS:

Strong, stiff, optically clear

Easy to fabricate, machine,

and thermoform

Easy to solvent bond

Good dimensional stability

Good weathering

COMMON BRANDS:

OPTIX®

Plexiglas®

ACRYLITE®

STANDARD SIZES

| SHEET | Dimensions: 22.5 in x 46.5 in –108 in x 108.25 in |

| Thickness: 0.010 in – 2 in |

| RODS | Cast Outside Diameter: 0.250 in – 6 in |

| Extruded Outside Diameter: 0.062 in – 3 in | |

| Extruded Square Outside Diameter: 0.125 in – 1.500 in |

| TUBES | Cast Outside Diameter: 1.250 in – 12 in |

| Extruded Outside Diameter: 0.250 in – 6 in |

OPTIONS AVAILABLE

| TEXTURE, SURFACE, PATTERN | Abrasion Resistant (AR1, AR2), Non-Glare, Light Diffusion, P95, P99, Mirror |

| GRADES | General Purpose, Abrasion Resistant, 40% Impact Modified, 70% Impact Modified, Light Diffusing, Bullet Resistant, Sign-Grade, Anti Reflective/ Non-Glare, ESD (Electrostatic Dissipative), Antimicrobial, Digital |

TYPES AND COLORS

| CAST | Clear Opaque: Translucent: Transparent: |

| EXTRUDED | Clear Opaque: Transparent/Translucent: Fluorescent: Metallic: |

| MIRROR | Blue 1000, Blue 2069, Blue 2424, Purple 1020, Gray 1050, Gray 2064, Orange 1119, Gold 1300, Red 1310, Red 1400, Red 2423, Bronze 2404, Bronze 1600, Green 4674, Green 2414, Pink 1450, Teal 2120, Yellow 2208, Amber 2422, Mirrored |

| PRINT GRADE | White 7328 Translucent |

| LIGHT DIFFUSING | Blue 2050, Blue 2114, Red 2157, Red 2283, Red 2793, White 2406, White 2447, White 7328, Yellow 2037, Clear, Colorless, Translucent, White |

ACRYLIC ENGINEERING PLASTICS DETAILS

Length, width, thickness, and diameter tolerances vary by size, by manufacturer, brand, and grade. Custom sizes and colors available upon request. Acrylic rod and tube are also available in a wide range of colors.

Cast and extruded acrylic available in paper and film mask.

Acrylic Properties and Material Options

Extruded Acrylic– Extruded acrylic sheet can be manufactured to any length, which often results in cost savings since yield loss can be minimized when parts are cut from custom sheet sizes. Extruded acrylic is also the easiest grade to thermoform and the easiest to bond using solvent cements.

Cast Acrylic– Cast acrylic sheet has better chemical resistance and superior machining characteristics compared with extruded acrylic.

Continuous Cast Acrylic – In addition to the better chemical resistance and superior machining characteristics, OPTIX® L-Series provides a more uniform thickness and larger sheet sizes due to the nature of the continuous cast manufacturing method.

Acrylic for Architectural Applications– Acrylic’s clarity, light weight, impact resistance, and weather resistance, make this material a popular choice for architectural applications. Acrylic sheet is used in everything from windows and wall partitions to lighting fixtures and canopies.

Acrylic for Transportation Applications– Acrylic is used throughout the transportation industry in instrument panels, windows, windshields, and mirrors.

AMGARD™ Acrylic for Safety Shields– A transparent sheet formulated with a silver ion antimicrobial agent that protects the sheet surface against the growth of microorganisms such as bacteria, mold and mildew that cause stains and odors. AMGARD™ provides additional surface protection between cleanings and complies with applicable EPA requirements as a Treated Article.

OPTIX® DA Acrylic for Digital Printing– OPTIX® DA is specifically designed to provide optimal adhesion of UV curing inks without the need for adhesion promoters.

OPTIX® LD Acrylic for Light Diffusion– OPTIX® LD light diffusing acrylic sheet provides superior diffusion properties and weatherability allowing for greater sign design flexibility with slim profile channel letters. Visible hot spots and luminance fluctuations are eliminated without affecting the light transmission properties. Offered in a wide variety of stock sizes, colors and patterns.

OPTIX® 95 Acrylic– OPTIX® 95 has a matte finish on one side and provides a decorative effect that reduces surface reflections. Smudge and fingerprint resistant.

OPTIX® 95 LED Light Diffusing Acrylic– OPTIX® 95 LED offers a soft satin appearance on one side, combining high efficiency with excellent diffusing properties, making it ideal for LED lighting applications.

OPTIX® Frost LED Light Diffusing Acrylic– OPTIX® Frost LED acrylic sheet provides a soft satin appearance on 2 sides, combining high efficiency with excellent diffusing properties, making it ideal for LED lighting applications.

OPTIX® LED Satin – OPTIX® LED Satin architectural lighting panels enable narrower dimensions and thinner gauges while maintaining hiding power. UL Certification: UL94HB, RTI90, F1 outdoor suitability.

OPTIX® Lum 1 – OPTIX® Lum 1 diffusive sheet is a premium white acrylic sheet which provides both high transmission and excellent lamp hiding capabilities.

OPTIX® Flexilume Specialty Film – OPTIX® Flexilume film is best used as an overlay film for lenses or louvers or as contour inserts with perforated metals, profiles or reflecting surfaces. OPTIX® Flexilume features a matte/smooth finish and excellent uniformity.

OPTIX® Flex G2 Diffusive Overlay Film – OPTIX® Flex G2 film is best used as an overlay film for lenses or louvers, or as contour inserts with perforated metals, profiles or reflecting surfaces. Standard OPTIX® Flex G2 is warm in transmittance and cool in reflectance. Enhanced surface diffusion one-side satin/one-side matte; eliminates glossy surface.

OPTIX® Pattern 12 (PL-21) Panels – OPTIX® Pattern 12 (PL-21) Prismatic Acrylic lighting panels offer excellent efficiency and direct glare control, while providing an attractive appearance. The PL-21 features a 3/16″ square base female conical pattern. It fits standard ceiling grids for easy installation.

KSH® Acrylic Lighting Panels and Overlays for Light Diffusing– KSH® panels are prismatic lighting panels that eliminate glare and obscure fluorescent and HID (high intensity discharge) lamps. Acrylic boards are suitable for various size areas and available in several prismatic options. KSH® high transmission acrylic overlay sheets are used to diffuse lamp images and provide a more uniform surface brightness.

Plexiglas® Sylk Light Diffusing Acrylic– Plexiglas® Sylk acrylic sheet with a soft texture throughout maintains that texture after bending and forming. It is easy to fabricate and thermoform. UL 94 HB.

FDA Compliant Acrylic– Acrylic glass is available in FDA compliant grades.

Cut-to-Size Acrylic Sheet– Acrylic is available in “cut-to-size” or “run-to-size” sheet options. Gain the flexibility of buying acrylic how you need transparent plastic sheets. – save time, eliminate scrap, improve your productivity, and reduce wear and tear on your equipment.

Acrylic Packs– Some grades of Acrylic sheet are sold in convenient packs ranging from 4-12 sheets such as Clear OPTIX® Acrylic and Impact Modified Acrylic.

Acrylic Rods and Tubes– Acrylic rod supplier, square rod, and tube are available in a wide range of sizes. These are often used for point-of-purchase display applications.

Tech Tip– A number of coatings can be applied to a sheet or finished part for performance enhancing characteristics such as scratch resistance, anti-fogging, glare reduction, and solar reflective.

TYPICAL PROPERTIES OF ACRYLIC ENGINEERING PLASTIC

| UNITS | ASTM TEST | CONTINUOUSLY PROCESSED ACRYLIC SHEET | |

|---|---|---|---|

| Tensile strength | psi | D638 | 10,000 |

| Flexural modulus | psi | D790 | 480,000 |

| Izod impact (notched) | ft-lbs/in of notch | D256 | 0.4 |

| Heat deflection temperature @ 264 psi | °F | D648 | 195 |

| Maximum continuous service temperature in air | °F | 160 | |

| Water absorption (immersion 24 hours) | % | D570 | 0.20 |

| Coefficient of linear thermal expansion | in/in/°Fx10-5 | D696 | 4.0 |

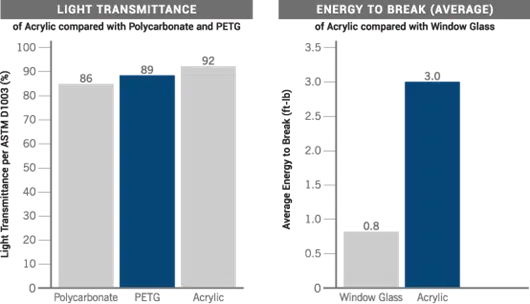

| Light transmittance | % | D1003 | 92 |

Prices may vary by brand name. please ask yourself

Please ask your Petrone Thermoplast representative for more specific information about a single brand.

Explore the physical, mechanical, thermal, electrical and optical properties of ABS. Sort, compare and find the appropriate ABS plastic material for your application using our interactive properties table.

Representative for more specific information about a personal brand.

Popular Plastic Material Comparison:

Acrylic vs Polycarbonate – With these strong, hard and clear plastics, the difference often comes down to: How tough?

Explore the physical, mechanical, thermal, electrical and optical properties of acrylic.

Sort, compare and find suitable plastic materials for your application using our interactive properties table.

ACRYLIC MATERIAL PROPERTIES COMPARISON GRAPHS