PPS Materials (Polyphenylene Sulfide)

PPS Materials (Polyphenylene Sulfide) PPS is used in filter fabrics for coal boilers, papermaking felts, electrical insulation, film capacitors, special membranes, gaskets and packing. PPS is a precursor to a conductive polymer of the semi-flexible rod polymer family. Polyphenylene sulfide is an engineering plastic which is mainly used now as a high performance thermoplastics. PPS is marketed by Petron Thermoplast Manufacturer in India. This is one of the best company for Engineering Plastics. The synthesis of PPS has established challenges. It has been achieved via extra polycondensation with the Suzuki coupling method.

Early efforts commonly produced black, insoluble powders that have been hard to characterize. For example 1962 paper reports “The strong glowed red-warm in a Bunsen flame, and not using a proof of flame formation, and disappeared most effective slowly.” Initially, the material’s chemical and thermal stability piqued curiosity in its synthesis. PPS Materials was utilised in rocket nozzles and textiles that needed to be thermally stable.

PPS IS WIDELY USED FOR:

- Semiconductor machinery components

- Scientific instrumentation parts

- Seals

- Pump and valve components

- Bearings and bushings (bearing grade)

- Electrical components

PERFORMANCE CHARACTERISTICS:

- Outstanding chemical resistance

- Resistant to hot water and steam

- Strong and stiff

- Can be used at elevated temperatures

- Good dimensional stability

- High dielectric strength

COMMON BRANDS:

- Sustatron PPS

- Tecatron®

STANDARD SIZES

| SHEET | Dimensions: 12 in x 12 in – 24 in x 48 in |

| Thickness: 0.375 in – 2 in |

| ROD | Outside Diameter: 0.375 in – 2.500 in |

OPTIONS AVAILABLE

| COLOR | Natural |

Length, width, thickness, and diameter tolerances vary by size, by manufacturer, brand, and grade. Custom sizes available upon request.

Tech Tip– PPS is often used as a lower cost alternative to replace PEEK at low to moderate temperatures.

TYPICAL PROPERTIES OF PPS MATERIALS

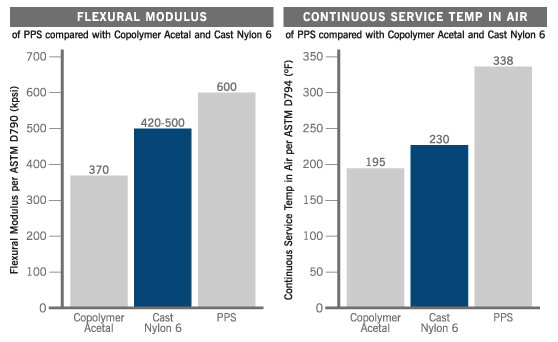

| UNITS | ASTM TEST | PPS | |

|---|---|---|---|

| Tensile strength | psi | D638 | 12,500 |

| Flexural modulus | psi | D790 | 600,000 |

| Izod impact (notched) | ft-lbs/in of notch | D256 | 0.5 |

| Heat deflection temperature @ 264 psi | °F | D648 | 220 |

| Maximum continuous service temperature in air | °F | 338 | |

| Water absorption (immersion 24 hours) | % | D570 | 0.02 |

| Coefficient of linear thermal expansion | in/in/°Fx10-5 | D696 | 4.0 |

Please ask your Petron Thermoplast representative for more specific information about a single brand.

Explore the physical, mechanical, thermal, electrical and optical properties of PPS Materials.

Sort, compare and find suitable plastic materials for your application using our interactive properties table.