PVC Materials (Polyvinyl Chloride)

PVC (Polyvinyl chloride), it is the third most frequently used synthetic plastic polymer on the planet. PVC (polyvinyl chloride) rigid is a robust, stiff, low-cost plastic that is easy to manufacture and bind using adhesives or solvents. Thermoplastic welding equipment may also be used to weld PVC. Tanks, valves, and pipe systems are commonly constructed using PVC Engineering Plastic Components.

PVC materials are utilised in a wide range of pipeline applications, from drinking water transportation to drainage and sophisticated fire-sprinkler systems. Safety, durability/cost-efficiency, environmental performance, and recyclability all contribute to the product’s appeal.

Over 80 years ago, the first PVC material (PVC Engineering Plastic Components) with used to pipe systems were built, and the majority of them are still in operation today. For subterranean pipelines, the estimated lifespan of a PVC (Polyvinyl Chloride) pipe is 100 years or more.

PVC IS WIDELY USED FOR:

- Welded chemical tanks

- Manifolds

- Valve and pump housings

- Fittings

- Piping systems

- Cabinets and working surfaces

PERFORMANCE CHARACTERISTICS:

- Strong and stiff

- Low cost

- Easy to machine and fabricate

- Easy to thermoform

- Easy to weld using thermoplastic welding equipment

- Easy to join using solvents or adhesives

COMMON BRANDS:

- Vintec® I

- Vintec® II

- Corzan® CPVC

STANDARD SIZES

| SHEET | Dimensions: 12 in x 12 in – 60 in x 120 in |

| Thickness: 0.062 in – 4 in |

| PANELS | Dimensions: Antimicrobial Panel 48 in x 96 in – 48 in x 120 inInterlocking Liner Panel 16 in x 96 in – 16 in x 240 in |

| Thickness: Antimicrobial Panel 2 mm – 2.5 mmInterlocking Liner Panel 0.5 in (12.7 mm) |

| ROD | Outside Diameter: 0.250 in – 14 in |

OPTIONS AVAILABLE

| COLOR | Sheet: Gray, White, ClearAntimicrobial Panel: White, Beige, Ocean Blue, Green GrapeRod: Gray, White, Black |

| GRADES | Type 1, Type 2, CPVC, Antimicrobial Panels, |

Length, width, thickness, and diameter tolerances vary by size, by manufacturer, brand, and grade. Custom sizes available along with FDA compliant, USP Class VI compliant, and medical grade options.

PVC Properties and Material Options

PVC Type 1– Normal impact, excellent chemical and corrosion resistance, easy to fabricate, weld or machine.

Clear PVC Type 1– Offering superior chemical resistance and favorable impact strength, clear PVC is an excellent substitute for transparent plastics such as acrylic and polycarbonate. UL 94 V-0 rating makes it a favorable choice for applications that need flame retardant materials for sight windows and transparent dividers in semiconductor, pharmaceutical, and even food service or processing settings. Clear PVC can be heat formed and easily machined or fabricated.

PVC Type 2– High impact, excellent chemical and corrosion resistance, easy to fabricate, weld or machine.

CPVC– High heat and corrosion resistant CPVC sheet. Excellent corrosion resistance at elevated temperatures.

Antimicrobial Panel – PALCLAD™ PRO HYG antimicrobial PVC wall cladding systems help maintain a sterile environment by killing or inhibiting the growth of a wide variety of pathogens.

Bonding PVC– Easily achieved by using Plexus® MA300, a fast-setting methacrylate adhesive, to create stronger bonds than the PVC itself.

Tech Tip– PVC also comes in fire safe materials specially formulated to exceed FM 4910 fire compliances in semiconductor and cleanroom applications.

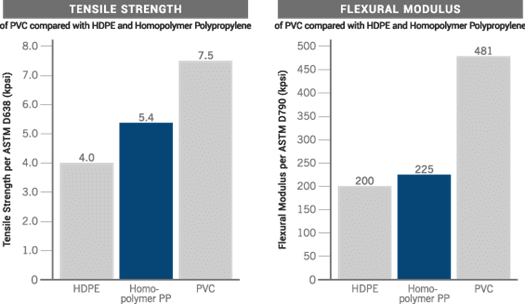

TYPICAL PROPERTIES OF PVC

| UNITS | ASTM TEST | PVC (RIGID) | |

|---|---|---|---|

| Tensile strength | psi | D638 | 7,500 |

| Flexural modulus | psi | D790 | 481,000 |

| Izod impact (notched) | ft-lbs/in of notch | D256 | 1.0 |

| Heat deflection temperature @ 264 psi | °F | D648 | 158 |

| Maximum continuous service temperature in air | °F | 140 | |

| Water absorption (immersion 24 hours) | % | D570 | 0.06 |

| Coefficient of linear thermal expansion | in/in/°Fx10-5 | D696 | 3.2 |

Please ask your Petron Thermoplast representative for more specific information about an individual brand.

Explore the physical, mechanical, thermal, electrical, and optical properties of PVC.

Sort, compare, and find the plastic material suited for your application using our interactive properties table.