Pipeline and process repair clamps are meant to be put on damaged or leaky pipework, enclosing the defect inside the clamp body and restoring pressure integrity by engaging mechanical seals and locks on the good parent pipe.

Process piping maintenance on oil and gas pipelines and process facilities has been made easier by developing a pipe repair clamp.

What do You Know about the Structural Repair Clamps of pipelines?

Structural Repair Clamps give pressure containment and radial support to the pipe when the grout is used. When a Pressure Containment Clamp is equipped with taper locks to provide axial constraint and structural integrity, it becomes a Structural Clamp. The locks are put up in opposing pairs, gripping the pipe on both sides of the flaw. The locks are designed to transfer the pipe’s whole axial force to the clamp body, allowing it to bear complete pipeline separation stresses.

Why are Pipe Clamps Used?

Pipe clamps may be found in various situations, including the home, the workplace, and the outdoors. They’re utilized to constrain, secure, and guide tubes or conduits for various plumbing, heating, and electrical applications.

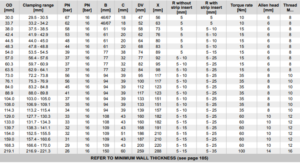

Each pipe clamp set comprises two parts: a fixed foot with an adjustable clamp plate and an adjustable foot with a flat plate that adjusts along the pipe’s length. The pipe repair clamp will establish a seal over the leak once it is in place. A decent pipe repair clamp can last for many years when used correctly. The below table can describe the pipe repair clamps.

Progressive Sealing Effect

• The gradual sealing action of the sealing gasket is a patented feature.

• Due to the flow via the pressure equalization channel, the force on the sealing lips increases as the pressure in the pipe rises.

• The gasket isn’t subjected to a lot of pressure.

• Minimal installation torque applied.

• Elasticity that lasts a long time.

• In the case of temperature changes, the free space between the sealing lips acts as a reservoir for the gasket.

Progressive Anchoring Effect

• The pipe couplings may be used on standard plain-ended pipes without pipe end preparation.

• Tightening the bolts to the appropriate torque

• The anchoring ring’s teeth are specially designed to bite into the pipe’s surface.

• An axial restraint connection is constructed in the same way.

• If the pipe’s axial loading increases due to increasing internal pressure or external factors.

• To compensate, teeth bite even deeper into the pipe.

• Basic pipeline anchoring solutions are available for hard surfaces like iron, copper, and steel and softer surfaces like aluminium and plastic.

• The anchoring ring keeps flexibility in service due to differential hardening.

Stress-Free Joining

• In the main pipe couplings, the sealing and anchoring functions are independent.

• You are anchoring. The housing, which connects the pipe ends, exerts no forces and reduces stress on the different components. The housing’s spring effect and the anchoring ring’s spring effect result in a flexible grasping relationship.

• As a result, the piping is not stiff but flexible at every link.

• The sealing gasket is placed on the pipe’s surface and allows the pipe ends to move freely.

Application Benefits

Engines, gears, turbines, generators, and other oscillating machinery

Engine to the hull, pump to the pipeline, fuel pump to feeds, and other transitions between oscillating and rigid systems.

• No tension transfer

• Interrupts oscillating circuits.

• No lead fractures

• Increased life expectancy

• Stress-free installation

• Flexible pipe system.

• Coupling and compensator in one

• Quick detachable

Different Types of Pipe Repair Clamps

The exterior pipe surface condition is one of the most important features of a damaged/deteriorated pipe that determines the repair component that should be used with a pipe repair clamp.

If an elastomeric seal cannot provide sufficient sealing forces near the damage or in the relatively unaffected areas adjacent to the major damage (these areas being used to seal stand-off repair clamps), the external pipe surface may need to be re-instated with some form of filler material. Take a look at the several types of pipe repair clamps available:

Patch-Clamp

A basic patch clamp or a customized pin-hole leak repair clamp can be used to fix a minor pin-hole leak on a segment of pipe. A locator pin directs a pointed cone seal into the leaking hole in the pin-hole leak repair clamp. A force screw is then used to compress the cone seal, and after the seal is crushed, the pin may be withdrawn, completing the seal.

Pin-Hole Leak Repair Clamp

The usage of simple circular sleeves can strengthen a damaged portion of the pipe. The sleeves are made up of two parts that fit snugly around the pipe’s outer diameter. The two parts are longitudinally fused (backing strips are used for the longitudinal welds to prevent weld-induced damage, or mechanical property changes, at the pipe surface).

Final Thoughts

Installation may be done with minimum disturbance to the system’s piping or functioning of the pipe repair clamp. Pressure Containment Clamps are meant to be fitted on damaged or leaking pipework, enclosing the defect inside the clamp body and restoring pressure integrity via mechanical seals contacting the sound parent pipe.

You can also see – Acrylic Plastic Sheet | Polycarbonate Sheet

Pingback: Simpleplay บริษัทผู้พัฒนาเกมส์พรีเมียม

Pingback: Roof Replacement Cost Calculator

Pingback: เช่ารถตู้พร้อมคนขับ

Pingback: ทำความรู้จักกับ lottorich28

Pingback: หวยหุ้นไทย

Pingback: expanseเว็บสล็อตใหม่ล่าสุด