Polyvinylidene fluoride or PVDF, also known as polyvinylidene difluoride and PVF2. PVDF is a pyroelectric and piezoelectric polymer used to produce a wide range of high-purity, high-strength, and high-chemical-resistance products for use in the electrical, electronic, biomedical, construction, fluid-systems, oil-and-gas, and food industries. It is a fluoropolymer, a class of specialised, versatile polymeric materials. It has many distinct properties due to a strong bond between its carbon atoms and fluorine atoms, along with that fluorine shielding of the carbon backbone.

What is PVDF?

PVDF is a thermoplastic semicrystalline polymer. The degree of crystallinity varies between 35 and 70%, depending on the preparation method. It has a unique mixture of mechanical and electrical properties (i.e., piezoelectricity) and maintains high purity standards. It is also resistant to most chemicals, including solvents, acids, and hydrocarbons.

PVDF’s molecular and crystal structures change depending on how the samples are prepared.

PVDF’s complex crystalline polymorphism is not found in other synthetic polymers. PVDF has five crystalline forms: alpha, beta, gamma, delta, and epsilon.

The beta phase is the most common and forms the major phases, along with the alpha and gamma phases.

- The alpha phase is nonpolar and is produced by melt crystallisation at any temperature during the melting process.

- The beta phase is an oriented phase caused by mechanical deformation of the specimen via uniaxial or biaxial mechanical drawing at temperatures below 70 °C. It is the most commonly used in piezoelectric applications.

- The gamma phase is a subtype that appears under certain conditions. It can be produced by melt casting or solution casting at temperatures close to the melting point of the alpha phase.

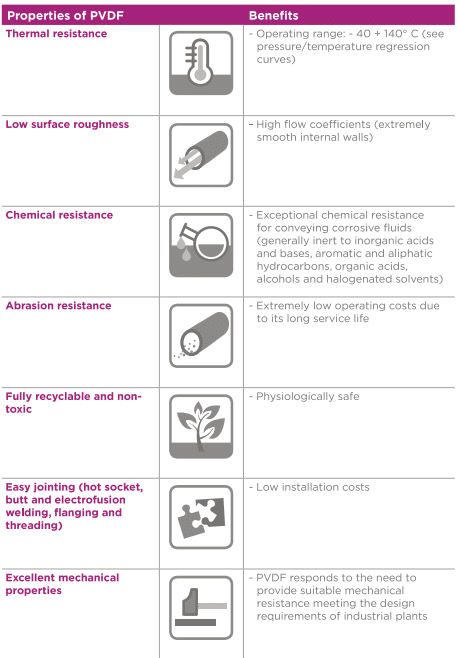

Below is the chart which depicts the benefits and properties of PVDF.

How is PVDF produced?

PVDF or Polyvinylidene fluoride is made by polymerising the monomer vinylidene difluoride using free radicals (1,1-difluoroethylene). This process occurs in the presence of an emulsion. At that time, temperatures range from 10 to 150 °C, and pressures range from 10 atm to 300 atm.

The PVDF material is operated and fabricated into parts and coatings by melt casting, spin coating, solution casting, and film casting.

- Melt Casting: the polymer gets warmth until it melts, then poured into a mould of the desired shape until it solidifies and cools.

- Solution casting: The polymer is melted in an appropriate solution to make porous polymer membranes. The temperature, polarity, and molecular weight of the solvent play a role in PVDF solubility.

- Spin coating: from the higher beta-phase of the polymer, thin films are stretched or subjected to high pressure or an electric field to develop piezoelectric thin-film devices.

- Film casting: the polymer is processed into uniform, high-quality films or thin sheets using a customised extrusion procedure. It is also referred to as film extrusion.

Characteristics of PVDF:

Some of the most prominent characteristics of PVDF are listed below.

- Excellent thermal stability,

- Resistance to UV light and high-energy radiation,

- High fatigue resistance during cyclic loading,

- Dielectric strength is very high,

- High creep resistance under long-term stress (creep),

- Most chemicals and solvents are resistant to it.

- Water absorption is low,

- Abrasion resistance is excellent,

- It is known to be mechanically more robust than other fluoropolymers (i.e., PTFE),

- Meets food processing application standards (non-toxic and resistant to bacteria and fungi).

As PVDF is unique and useful thus, it has different characteristics from different application aspects.

Mechanical properties of PVDF:

| Tensile strength (at 23°C) | 9 – 120 MPa |

| Compressive strength (at 23°C) | 13.8 – 172 MPa |

| Elongation at yield (at 23°C) | 3.5 – 40 % |

| Yield strength (at 23°C) | 4.8 – 120 MPa |

| Elastic modulus (at 23°C) | 0.03 – 17.1 GPa |

| Flexural modulus (at 23°C) | 0.07 – 20.9 GPa |

| Density (at 23°C) | 0.7 – 1.89 g/cm3 |

| Water absorption (at 23°C) | 0.01 – 0.5 % |

Thermal properties of PVDF:

| Melting point | 92 – 342 °C |

| Specific heat capacity (at 23°C) | 665 – 1500 J/kg.K |

| Thermal conductivity (at 23°C) | 0.13 – 0.19 W/m.K |

| Glass transition temperature | -43.3 – -38.3 °C |

| Coefficient of thermal expansion (at 23°C) | 2*10-5 – 2.6*10-4 /K |

Electrical properties of PVDF:

| Dielectric strength (at 23°C) | 1.4 – 110 kV/mm |

| Surface resistivity (at 23°C) | 1*1010 – 1*1014 Ohm/sq |

| Dielectric constant (at 23°C) | 6 – 8 |

What are the major PVDF applications?

The accompanying are some of the most common PVDF component applications.

- High purity semiconductors,

- Nuclear waste processing,

- Pipe and pumping applications,

- General chemical processing,

- Membranes for water treatment,

- Biomedical, artificial membranes, wire and cable isolators,

- Food and pharmaceutical processing,

- Battery and sensor manufacturing and architectural coating are all examples of applications.

What is PVDF for additive manufacturing?

- Due to mechanical strain generation, materials with piezoelectric functionalities tend to elongate when subjected to an electric field. These materials are critical for 3D printing electronic devices like sensors and actuators.

- In addition to its piezoelectric properties, PVDF is lead-free, making it suitable for biomedical applications and the food industry.

- It is also a flexible material required in high displacement applications. The sensitivity of piezoelectric PVDF sensors is directly influenced by the concentration and orientation of the polar phases.

- Filament fused fabrication (FFF) is also known as fused deposition modelling. It is the most commonly used 3D printing method for printing PVDF products (FDM). Extruding a PVDF filament through a heated nozzle liquefies the printing material.

- PVDF filaments for additive manufacturing have a high resistance to UV, weathering, oxidation, and long-term performance up to 120 °C. Because PVDF has a low melting point, it can be used in a wider range of printer models.

Petron Thermoplast makes the best quality PVDF materials. Though, pipes and fittings, Li-ion batteries, and semiconductors dominate the PVDF market. We offer Polyvinylidene fluoride at an affordable price.

You can also read – Acrylic Plastic Sheet | Polycarbonate Sheet

Pingback: ติดตั้งสถานีก๊าซ

Pingback: marbo 9000

Pingback: herbal supplements

Pingback: c2c chat

Pingback: massage Bangkok

Pingback: สล็อตวอเลท ฝากถอนไว ไม่ต้องแจ้งสลิป

Pingback: 7slots

Pingback: Chicken Road

Pingback: pg slot