Introduction

In the world of modern manufacturing, thermoplastic products have become a cornerstone of various industries, offering versatility, durability, and cost-effectiveness. From everyday household items to cutting-edge industrial machined components, these products play a pivotal role. This article delves into the concept of thermoplastic products, exploring their properties, applications, benefits, and manufacturing processes.

Understanding Thermoplastic Products

Defining Thermoplastics

Thermoplastics are a class of polymers characterized by their ability to repeatedly soften and harden when subjected to heat. Unlike thermosetting plastics, which undergo irreversible chemical changes when heated, thermoplastics retain their molecular structure even after cooling. This distinctive feature allows them to be molded and reshaped multiple times without compromising their integrity.

Properties of Thermoplastic Products

- Flexibility and Resilience: Thermoplastic products are known for their high flexibility and resilience. They can endure repeated bending, stretching, and impact without breaking.

- Lightweight: Most thermoplastics have a low density, making them exceptionally lightweight. This property is particularly advantageous in applications where weight reduction is crucial, such as aerospace and automotive industries.

- Chemical Resistance: Thermoplastic products exhibit remarkable resistance to a wide range of chemicals, acids, and bases. This makes them suitable for applications in corrosive environments.

- Ease of Processing: The processing of thermoplastics is relatively straightforward. They can be melted, molded into various shapes using different techniques, and easily fabricated.

- Recyclability: Unlike thermosetting plastics, thermoplastics can be melted down and reprocessed multiple times without a significant loss in their properties. This characteristic aligns well with sustainability efforts.

Applications of Thermoplastic Products

1. Consumer Goods

Thermoplastic products are prevalent in everyday consumer items. From food packaging to toys, the versatility of thermoplastics allows for a broad range of designs and functionalities.

2. Medical Devices

In the medical field, thermoplastics find applications in devices such as syringes, IV bags, and prosthetics. Their biocompatibility, lightweight nature, and sterilization compatibility make them ideal for medical use.

3. Automotive Industry

Thermoplastics have revolutionized the automotive industry. They are used in manufacturing interior components, exterior body panels, and even engine parts. Their lightweight nature contributes to improved fuel efficiency.

4. Electronics

The electronics industry benefits from thermoplastics due to their insulating properties. Connectors, switches, and casings are often made from thermoplastic materials.

5. Construction

Thermoplastics are finding their way into the construction sector. Piping systems, roofing materials, and insulation products made from thermoplastics offer durability and resistance to harsh weather conditions.

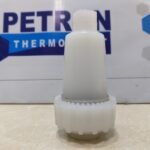

6. Industrial Components

Industries rely on thermoplastic products for manufacturing components like gears, bearings, and conveyor belts. Their resistance to wear and tear, coupled with chemical resistance, makes them suitable for industrial environments.

Manufacturing of Thermoplastic Products

1. Injection Molding

Injection molding is one of the most common techniques for manufacturing thermoplastic products. Molten thermoplastic material is injected into a mold, where it cools and solidifies to take the desired shape.

2. Extrusion

Extrusion involves forcing molten thermoplastic through a shaped die to produce continuous profiles. This method is used for creating products like pipes, tubes, and sheets.

3. Blow Molding

Blow molding is used to create hollow thermoplastic products, such as bottles and containers. The molten plastic is inflated in a mold, taking the shape of the mold as it cools.

4. Thermoforming

Thermoforming is the process of heating a thermoplastic sheet until it becomes pliable and then forming it over a mold to achieve the desired shape. This method is commonly used for creating packaging materials and disposable items.

Benefits of Using Thermoplastic Products

- Cost-Effective: Thermoplastics are often more affordable than other materials, reducing manufacturing costs.

- Design Flexibility: Their ease of processing allows for intricate and complex designs, meeting specific requirements.

- Shorter Production Cycle: Thermoplastic products can be produced quickly, reducing time-to-market.

- Environmental Impact: Recyclability and reduced energy consumption during production contribute to a lower environmental footprint.

Conclusion

Thermoplastic products have revolutionized the manufacturing landscape across diverse industries. Their versatility, durability, and cost-effectiveness make them a go-to choice for various applications, from consumer goods to industrial components. As technology advances and sustainability becomes a top priority, the role of thermoplastics is only expected to grow, shaping a more efficient and eco-friendly future. Whether it’s the smartphone in your hand or the car you drive, there’s a good chance that thermoplastic products have played a vital role in their creation.

Incorporating natural language and the targeted keyword “thermoplastic products” seamlessly throughout this blog has enabled us to provide a comprehensive overview of the subject. As you can see, thermoplastic products have a significant impact on our daily lives, industries, and the world of manufacturing as a whole.

Visit Petron Thermoplast Today

If you’re seeking the best quality thermoplastic products that blend innovation, durability, and precision, look no further than Petron Thermoplast. With our rich industry experience, cutting-edge technology, and unwavering dedication to customer satisfaction, we’re your partner of choice in the world of thermoplastics. Visit our website or get in touch with our team today to explore our extensive product range and discover how we can elevate your projects with exceptional thermoplastic solutions.

Remember, at Petron Thermoplast, excellence is not just a goal – it’s our standard.

- Why UPVC is the Best Choice for Piping & Plumbing Systems?

- The Growing Demand for PVDF Filters in Semiconductor Manufacturing

- The Future of UPVC Ball Valves in Industrial Fluid Control

- Why PVDF Check Valves Are the Best Choice for Harsh Chemical Environments

- Top PVDF Ball Valve Manufacturers: Quality, Durability & Performance