Introduction

In today’s blog we will discuss the top 12 reasons to use different types of non return valves. In the realm of fluid control and management, the significance of non-return valves cannot be overstated. These unassuming yet vital precision machined components play a crucial role in maintaining the flow direction, preventing backflow, and ensuring the efficiency of various systems. Among the diverse array of non-return valves available, the CPVC Non Return Valve stands as a prominent choice for numerous applications. In this comprehensive article, we will delve into the reasons why it is essential to employ different types of non-return valves, with a particular focus on the benefits and unique characteristics of Cpvc Non Return Valves.

Understanding Non-Return Valves

Before we explore the specific advantages of using various types of non-return valves, it is imperative to grasp the fundamentals of these valves. Non-return valves, also known as check valves or one-way valves, are mechanical devices designed to allow fluid flow in one direction while preventing the reverse flow. Their unidirectional flow control ensures the avoidance of backflow, minimizing the risk of contamination, pressure surges, and damage to the system.

Top 12 Reasons to Use Different Types Of Non Return Valves

Here are the top 12 reasons to use different types of non return valves:

1. Ensuring Optimal Flow Control

One of the primary reasons for employing different types of non-return valves lies in their ability to ensure optimal flow control in diverse scenarios. In a myriad of fluid handling systems, maintaining the proper direction of flow is paramount to their effective operation. Non-return valves provide the assurance that fluids move in the intended direction, thereby maximizing efficiency and preventing potential complications.

2. Protecting Pumps and Compressors

In systems that involve pumps or compressors, backflow can cause significant damage. When a pump stops, the fluid’s momentum may cause it to flow in the reverse direction, leading to “water hammer” effects, pressure spikes, and even mechanical failure. The installation of a non-return valve, such as the Cpvc Non Return Valve, at the pump outlet prevents this backflow, safeguarding the pump and extending its lifespan.

3. Preventing Contamination and Cross-Contamination

Certain applications, especially in the pharmaceutical, food, and beverage industries, demand stringent hygiene and safety measures. Non-return valves play a crucial role in preventing contamination and cross-contamination between different fluids or substances. By maintaining a unidirectional flow, these valves ensure that potentially hazardous materials do not mix with others, assuring product integrity and consumer safety.

4. Reducing Water Hammer Effects

Water hammer is a hydraulic phenomenon characterized by pressure surges resulting from sudden changes in fluid flow. These pressure waves can cause severe damage to pipes, fittings, and other system components. Non-return valves help mitigate water hammer effects by providing a controlled closing mechanism that prevents the rapid reversal of flow and dissipates excess energy, maintaining system stability.

5. Enhancing System Efficiency

Efficiency is a critical factor in any fluid handling system, as it directly impacts energy consumption and operational costs. By incorporating non-return valves at strategic points in the system, engineers can optimize fluid flow and minimize energy losses, ultimately leading to enhanced overall system efficiency.

6. Supporting Multi-System Applications

In complex industrial setups, multiple fluid systems often interact and rely on each other. Non-return valves enable the smooth functioning of these interconnected systems by allowing the required fluid to flow in the correct direction while preventing any unwanted backflow that could disrupt the balance of the entire network.

7. Adapting to Different Media and Environments

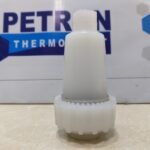

The versatility of non-return valves is noteworthy, as they can be constructed from various materials to suit different media and environmental conditions. For instance, the CPVC Non Return Valve, made from Chlorinated Polyvinyl Chloride (CPVC), exhibits excellent resistance to corrosion, making it ideal for applications involving corrosive fluids or harsh environments.

8. Ensuring Safety in Gas and Fluid Systems

In gas and fluid systems, especially those dealing with toxic or flammable substances, safety is of paramount importance. Non-return valves serve as a critical safety measure by preventing the unintentional reverse flow of hazardous materials, reducing the risk of accidents and potential harm to personnel and the environment.

9. Complying with Industry Regulations

Numerous industries are subject to stringent regulations and standards that govern fluid handling practices. The implementation of non-return valves is often mandatory to comply with these regulations, ensuring that systems meet the required safety and environmental standards.

10. Catering to Various Installation Configurations

Non-return valves come in various designs, including swing, lift, ball, and diaphragm types, among others. This wide range of configurations allows engineers and system designers to select the most suitable valve for specific installation needs, maximizing performance and adaptability.

11. Minimizing Maintenance and Downtime

The integration of non-return valves can significantly reduce maintenance requirements and downtime. By preventing backflow, these valves protect the system from potential damage and subsequent breakdowns, leading to longer operational periods and reduced maintenance costs.

Conclusion

Top 12 reasons to use different types of non return valves. The incorporation of different types of non-return valves, such as the versatile Cpvc Non Return Valve, offers a plethora of advantages across various fluid handling applications. From ensuring optimal flow control and protecting pumps to preventing contamination and complying with regulations, these valves play a pivotal role in enhancing system efficiency and safety. Whether in industrial, commercial, or residential settings, the prudent utilization of non-return valves is undoubtedly a wise investment for smooth, reliable, and efficient fluid management systems.

FAQs:

Q. What is the most common use of non-return valve?

A. The most common use of a non-return valve is to allow fluid or gas to flow in only one direction, preventing backflow and maintaining a unidirectional flow in plumbing, pumps, and various industrial applications.

Q. What are the benefits of a non-return valve?

A. A non-return valve, also known as a check valve, allows fluid or gas flow in one direction and prevents backflow. Its benefits include preventing system damage, maintaining pressure, and ensuring efficient flow control.

Q. What is the reason for using non-return valve in piping system?

A. A non-return valve is used in piping systems to allow flow in one direction only, preventing backflow and ensuring the fluid or gas moves in the desired direction without any reverse flow.

Q. Do non return valves reduce pressure?

A. No, non-return valves do not reduce pressure. They are designed to allow fluid flow in one direction only, preventing backflow. Pressure reduction requires a separate device like a pressure regulator.

- Why UPVC is the Best Choice for Piping & Plumbing Systems?

- The Growing Demand for PVDF Filters in Semiconductor Manufacturing

- The Future of UPVC Ball Valves in Industrial Fluid Control

- Why PVDF Check Valves Are the Best Choice for Harsh Chemical Environments

- Top PVDF Ball Valve Manufacturers: Quality, Durability & Performance

Pingback: get tokens

Pingback: MP3 Songs Free Download

Pingback: drag chain cable

Pingback: สล็อตค่ายนอกแตกดี

Pingback: ร้านแบตเตอรี่ใกล้ฉัน