- ABS

- Acetal Sheet

- Acrylic & Perspex

- Dry Wipe Board

- Engraving Plastic

- Mirrored Plastic Sheet

- Nylon 6

- Nylon 66

- PEEK Sheet

- PEI (Ultem)

- PET

- PET (Ertalyte)

- PETG

- Plastic Shims

- Polycarbonate

- Playground Plastic (HDPE)

- Polyethylene PE300 - HDPE

- Polyethylene PE500 - HMWPE

- Polyethylene PE1000 - UHMW

- Polypropylene

- Prismatic Diffuser Panels

- PTFE

- PVC

- PVC Foam (Foamex)

- PVDF

- Salbex Pressed PVC

- Vespel

- Vyon Breathable Plastic

- Metal Detectable Plastic

- Tufnol Industrial Laminates

- Glass Based Laminates

Description

Polypropylene sheet is a durable, lightweight engineering plastic with low water absorption and good acid, alkali, and organic solvent resistance. This material’s mechanical strength, impact resistance, and thermal/electrical insulating capabilities make it a popular choice in a wide range of sectors.

Because of its FDA certification, it is extensively utilized in the chemical industry as a lining for acid and chemical tanks, as well as in the food production industry. Polypropylene is easy to shape and weld at a recommended operating service temperature of -20°C to +80°C, although it can become brittle at lower temperatures.

Due to the low melting temperature of +160°C, drilling and milling for long periods of time is also not suggested. Our standard selection of Polypropylene sheets is available to buy online at Petron Thermoplast Direct by following the link above. Polypropylene sheet is offered in two flexible grades, PPH (Homopolymer) and PPC (Copolymer).

Applications

- Seals, insulators, ventilation ducts, pallets, drip pans, crash doors, and wall cladding are all examples of chemical apparatus. Polypropylene is also thermally and electrically insulating, as well as resistant to a wide range of acids, alkalis, and organic solvents, making it an excellent choice for fabrication projects in chemical and wastewater treatment plants.

Key Features

Temperature ranges from -20°C to +80°C.

Water absorption is quite low, as is density.

Dilute acids, cleaning chemicals, and a variety of solvents are all resistant to this material.

Machine, shape, and weld with ease.

The FDA has given its approval.

Polypropylene Homopolymer (PPH)

| Colour: | Sheet Size (mm): | Sheet Thickness (mm): |

|---|---|---|

| – | – | 45 50 55 60 70 80 100 110 120 130 140 150 200 |

| Natural | 3000 x 1500 | – – * * * * * * * * * * * – – – |

| Natural | 2000 x 1000 | * * * * * * * * * * * * * * * * |

| Beige | 4000 x 2000 | – – – – – * * * * * * * * * * * |

| Beige | 3000 x 1500 | – – * * * * * * * * * * * * * * |

| Beige | 2000 x 1000 | * * * * * * * * * * * * * * * * |

| Colour: | Sheet Size (mm): | Sheet Thickness (mm): |

|---|---|---|

| – | – | 1 1.5 2 3 4 5 6 8 10 12 15 20 25 30 35 40 |

| Natural | 3000 x 1500 | – – * * * * * * * * * * * – – – |

| Natural | 2000 x 1000 | * * * * * * * * * * * * * * * * |

| Beige | 4000 x 2000 | – – – – – * * * * * * * * * * * |

| Beige | 3000 x 1500 | – – * * * * * * * * * * * * * * |

| Beige | 2000 x 1000 | * * * * * * * * * * * * * * * * |

*Denotes standard sheet availability.

Note: If a specific colour of material is required, please state this in writing at the point of enquiry.

Polypropylene Copolymer (PPC)

| Colour: | Sheet Size (mm): | Sheet Thickness (mm): |

|---|---|---|

| – | – | 1 1.5 2 3 4.5 6 9 12 15 20 |

| Natural | 3000 x 1500 | * * * * * * * * * * |

| Natural | 2440 x 1220 | * * * * * * * * * – |

| Black | 3000 x 1500 | * * * * * * * * * * |

| Black | 2440 x 1220 | * * * * * * * * * – |

| White | 3000 x 1550 | * * * * * * * * * – |

| White | 2440 x 1220 | * * * * * * * * * – |

| Beige | 3000 x 1500 | * * * * * * * * * – |

| Beige | 2440 x 1220 | * * * * * * * * * – |

*Denotes standard sheet availability.

Note: If a specific colour of material is required, please state this in writing at the point of enquiry. Black polypropylene copolymer (PPC) in 3mm, 4.5mm and 6mm thick is typically stocked with an embossed pattern surface on one side and smooth on the other side as standard. When cutting or forming embossed polypropylene we treat the embossed side as being the top surface / outside of the formed or bonded article, unless we are advised otherwise in writing prior to order and we write back to confirm acceptance of a variation.

Related Products

Plastic Machining

Plastic Fabrication

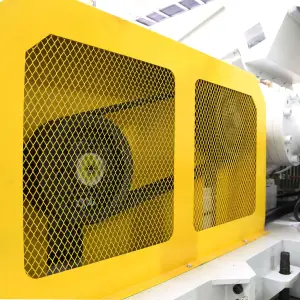

Machine Guards