Flow Meter Manufacturer

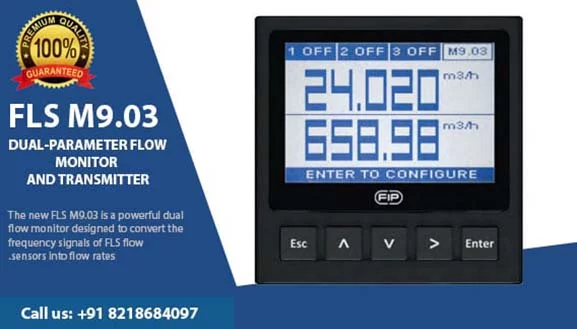

The new FLS M9.02 is a powerful flow monitor designed to convert the frequency signal of FLS flow sensors into a flow rate. M9.02 is equipped with a wide full graphic display4” which shows measured values clearly and a lot of other useful information. Moreover, due to a multicolour display plus a powerful backlight, measurement status can be determined easily from afar also. A tutorial software guarantees a mistake-proof and fast set up of every parameter. Calibration can be performed just fixing installation features or using a reference value through a new “in-line calibration”. A 4-20mAoutput is available to remote flow rate to a external device. A proper combination of digital outputs allows customized setups for any process to be controlled. The USB port on the rear part allows the upgrade of software offering a wide range of customization services both standard and on request. We are the best flow meter manufacturer in India and UAE also.

What is a Flow Meter?

What are the Various Types of Flow Meters?

1. Mechanical Flow Meters

These flow meters rely on moving parts to measure the flow rate of fluids. They work by counting the rotations or displacement of a mechanical element inside the meter.

- Turbine Flow Meters

- Positive Displacement Flow Meters

2. Ultrasonic Flow Meters

These flow meters use sound waves to measure the velocity of a fluid, which is then used to calculate the flow rate. They are particularly useful for clean liquids and gases.

- Transit-Time Ultrasonic Flow Meters

- Doppler Ultrasonic Flow Meters

3. Electromagnetic (Magnetic) Flow Meters

These flow meters apply Faraday’s Law of Electromagnetic Induction to measure the flow of conductive fluids. The voltage generated by the movement of the fluid through a magnetic field is proportional to the flow rate.

4. Thermal Flow Meters

Thermal flow meters measure the heat loss from a heated element as the fluid flows past it. The amount of heat lost is proportional to the flow rate.

5. Vortex Flow Meters

These meters measure the vortices shed by an obstruction placed in the fluid stream. The frequency of vortex shedding is proportional to the flow velocity, and thus the flow rate.

6. Mass Flow Meters

Mass flow meters measure the mass of the fluid passing through the meter rather than its volume.

7. Differential Pressure Flow Meters

These flow meters measure the difference in pressure before and after a constriction in the flow path, such as an orifice plate or venturi tube. This pressure difference is used to calculate flow rate.

8. Rotameters (Variable Area Flow Meters)

These meters measure flow by observing the position of a float within a tapered tube. As the flow rate increases, the float rises, and its position corresponds to the flow rate.

Which Type of Flow Meter is Best?

The best type of flow meter depends on the application, the type of fluid being measured (liquid, gas, or steam), accuracy requirements, and other environmental factors. Here are some of the most commonly used flow meters and their ideal applications:

- Coriolis Flow Meters

- Magnetic Flow Meters (Magmeters)

- Ultrasonic Flow Meters

- Vortex Flow Meters

- Turbine Flow Meters

- Positive Displacement Flow Meters

- Thermal Mass Flow Meters

Steps to Choose the Right Flow Meter?

Choosing the right flow meter involves several critical steps to ensure that the device will operate accurately and efficiently for your specific application. Here’s a step-by-step guide:

1. Identify the Fluid Type

- What is the medium? Is it a liquid, gas, or steam?

- Consider properties such as conductivity, density, viscosity, pressure, and temperature.

- Determine whether the fluid is clean or dirty, corrosive, or contains particulates.

2. Determine the Flow Measurement Type

- Volume vs. Mass Flow: Do you need to measure volume (e.g., liters per second) or mass (e.g., kilograms per hour)?

- Certain industries require mass flow measurements (e.g., chemical processing), while others use volumetric flow.

3. Establish Accuracy Requirements

- What level of precision is needed? Consider the acceptable error margin for your application.

- Flow meters like Coriolis and Magmeters offer high accuracy, while others like turbine meters may have more variability.

4. Define the Flow Rate Range

Minimum and Maximum Flow Rates: Ensure that the flow meter can measure the full range of expected flow rates.

Too high or too low flow rates may affect the performance or lifespan of certain types of flow meters.

5. Understand the Installation Environment

Pipe Size and Orientation: What is the diameter of the pipe, and how will the flow meter be installed (horizontally or vertically)?

Temperature and Pressure Conditions: Flow meters must be compatible with operating conditions, especially in high-temperature or high-pressure environments.

Space Constraints: Some flow meters are bulky and require sufficient space for installation and maintenance.

6. Choose Between Invasive and Non-Invasive Flow Meters

Invasive (Inline) Flow Meters: These are installed directly into the pipeline and may involve moving parts (e.g., turbine meters).

Non-Invasive (Clamp-On) Flow Meters: These types (e.g., ultrasonic flow meters) attach to the outside of the pipe and are preferred in applications where contamination must be avoided.

7. Consider Maintenance and Durability

Moving Parts: Flow meters with moving parts (e.g., turbine meters, positive displacement meters) may require more frequent maintenance.

Longevity: Magmeters and Coriolis meters tend to be more durable with fewer moving parts, leading to lower maintenance costs.

8. Check for Industry Standards and Certifications

Ensure the flow meter complies with the standards and regulations for your industry (e.g., ISO, CE, FDA, or ATEX for hazardous environments).

9. Evaluate Cost vs. Value

Initial Cost: Consider both the initial investment and the long-term operating costs, including calibration and maintenance.

Total Cost of Ownership (TCO): Sometimes a more expensive flow meter will offer better value due to higher accuracy, durability, or reduced maintenance.

10. Consider Special Application Requirements

Hazardous Locations: If the meter will be installed in a potentially explosive or corrosive environment, choose a meter designed for those conditions.

Bi-Directional Flow Measurement: If your process requires measuring flow in both directions, you may need a specific type of meter.

11. Consult with a Manufacturer

Once you’ve narrowed down your options, consult with experts or machined components manufacturers who can provide tailored advice based on your application requirements.

Applications of Flow Meter

Flow meters are used across various industries to measure the flow rate of liquids, gases, or steam. Here are some key applications for flow meters:

- Water and Wastewater Management

- Oil and Gas Industry

- Chemical and Petrochemical Industry

- Pharmaceutical and Biotechnology

- Food and Beverage Industry

- HVAC (Heating, Ventilation, and Air Conditioning)

- Automotive Industry

- Power Generation

- Aerospace and Aviation

- Agriculture and Irrigation

- Mining and Metals

- Marine Industry

Design Material of Digital Flow Meter

1. Body/Housing Material

- Stainless Steel (SS)

Brass - Aluminum

- Plastic/Polymer (e.g., PVC, PTFE, PP, PEEK)

2. Wetted Parts (Flow Sensor Components)

- Stainless Steel

- Hastelloy or Inconel

- Titanium

- Ceramic

- Teflon (PTFE)

- PEEK (Polyetheretherketone)

3. Seals and Gaskets

- Viton (FKM)

- EPDM (Ethylene Propylene Diene Monomer)

- PTFE (Teflon)

- Nitrile Rubber (NBR)

4. Electronics Enclosure

- Polycarbonate (PC)

- ABS (Acrylonitrile Butadiene Styrene)

- Die-Cast Aluminum

- Stainless Steel

5. Sensor Elements

- Platinum

- Nickel

Flow Measurement Tools

Flow measurement tools, also known as flow meters or flow sensors, are devices used to measure the flow rate of liquids, gases, or steam within a system. These tools vary in design and principle of operation depending on the type of fluid and the accuracy required. Here are some common flow measurement tools and their applications:

- Coriolis Flow Meters

- Magnetic Flow Meters (Magmeters)

- Ultrasonic Flow Meters

- Vortex Flow Meters

- Turbine Flow Meters

- Thermal Mass Flow Meters

- Positive Displacement Flow Meters

- Differential Pressure Flow Meters

- Rotameters (Variable Area Flow Meters)

- Paddlewheel Flow Meters

- Open Channel Flow Meters

- Venturi Flow Meters

- Oval Gear Flow Meters

- Electromagnetic Flow Meters

Key Questions to Ask when Choosing a Flow Meter

- What is the Fluid Type?

- What is the Flow Measurement Type?

- What Flow Rates Need to Be Measured?

- What are the Operating Conditions?

- What Level of Accuracy and Repeatability is Required?

- What is the Pipe Size and Configuration?

- What are the Installation and Maintenance Requirements?

- Is the Fluid Clean or Dirty?

- What are the Power and Signal Requirements?

- Are There Industry Standards or Compliance Requirements?

- What is the Total Cost of Ownership (TCO)?

- What Are the Special Application Needs?

- Is Non-Invasive Measurement Necessary?

- What is the Response Time of the Flow Meter?

- Is the Flow Meter Compatible with the Fluid’s Properties?

- Does the Flow Meter Need to Handle Multiple Fluids?

Conclusion

Petron Thermoplast offers a comprehensive range of flow measurement solutions designed to meet the diverse needs of various industries. By understanding the critical factors involved in flow measurement, including fluid properties, measurement requirements, operational conditions, and industry standards, Petron Thermoplast ensures that you receive tailored solutions that deliver accurate and reliable performance.

Our dedication to precision, durability, and customer satisfaction makes Petron Thermoplast the ideal choice for all your flow measurement challenges. Let us help you optimize your processes and achieve accurate measurements with confidence.

Flow Measurement System

Flow Measurement System

High-Quality Flow Meter Manufacturer | Petron Thermoplast

Petron Thermoplast is a leading flow meter manufacturer, providing high-quality flow meters for a wide range of industrial applications. We take pride in our commitment to delivering accurate and reliable solutions to meet our clients’ unique needs.

Our flow meters are manufactured using state-of-the-art technology and top-quality materials to ensure superior performance and durability. We offer a wide range of flow meters, including electromagnetic flow meters, ultrasonic flow meters, vortex flow meters, and more.

As a trusted flow meter manufacturer, we understand the importance of providing customizable solutions to meet our clients’ specific requirements. Our team of experts works closely with clients to design and manufacture flow meters that deliver accurate measurements and meet the demands of their applications.

Whether you need flow meters for the pharmaceutical, chemical, or food and beverage industry, Petron Thermoplast has got you covered. Our flow meters are engineered to meet the highest standards of quality and precision, ensuring accurate measurement and reliable performance.

APPLICATIONS OF FLOW METER

• Water treatment systems

• Industrial waste water treatment and recovery

• Water distribution

• Filtration systems

• Swimming pools & SPA

• Irrigation & Fertigation

• Leak detection

• Cooling water monitoring

• Processing and manufacturing industry

• Chemical production

MAIN FEATURES OF FLOW METER

• Wide full graphic display

• Multicolor backlight

• Help on board

• Installation flexibility

• Fast, intuitive and mistake-proof calibration software

• Mechanical relay for external device control

• Solid State Relays for programmable alarms

• Multilanguage menu

• USB port for software upgrading

Technical Data

General

• Associated sensors: FLS hall effect flow sensors with

frequency output or FLS F6.60 Flow sensor magmeters

• Materials:

– Case: ABS

– Display window: PC

– Panel & Wall gasket: silicone rubber

– Keypad: 5-button silicone rubber

• Display:

– LC full graphic display

– Backlight version: 3-colours

– Backlight activation: User adjustable with 5 levels of

timing

– Update rate: 1 second

– Enclosure: IP65 front

• Flow input range (frequency): 0÷1500Hz

• Flow input accuracy (frequency): 0,5%

Electrical

• Supply Voltage: 12 to 24 VDC ± 10% regulated

• Max Power Consumption: < 200 mA

• FLS hall effect flow Sensor power:

– 5 VDC @ < 20 mA

– Optically isolated from current loop

– Short circuit protected

• 1*Current output:

– 4-20 mA, isolated, fully adjustable and reversible

– Max loop impedance: 800 Ω @ 24 VDC – 250 Ω @

12 VDC

• 2*Solid State Relay output:

– User selectable as MIN alarm, MAX alarm, Pulse

Out, Window alarm, Off

– Optically isolated, 50 mA MAX sink, 24 VDC MAX

pull-up voltage

– Max pulse/min: 300

– Hysteresis: User selectable

• 1*Relay output:

– User selectable as MIN alarm, MAX alarm, Pulse

Out, Window alarm, Off

– Mechanical SPDT contact

– Expected mechanical life (min. operations): 107

– Expected electrical life (min. operations): 105 N.O./

N.C.switching capacity 5A/240VAC

– Max pulse/min: 60

– Hysteresis: User selectable

Environmental

• Operating temperature: -10 to +70°C (+14 to +158 °F)

• Storage temperature: -30 to +80°C (-22 to +176 °F)

• Relative humidity: 0 to 95% not condensing

Standards & Approvals

• Manufactured under ISO 9001

• Manufactured under ISO 14001

• CE

• RoHS Compliant

• EAC

• FDA on request for paddlewheel in C-PVC/EPDM,

PVDF/EPDM, SS316L/EPDM.

WIRING CONNECTIONS

Rear Terminal View

M9.02 Flow Monitor and Transmitter

| Part No. | Description/Name | Power supply | Wire power Technology | Sensor Input | Output | Weight (gr.) |

|---|---|---|---|---|---|---|

| M9.02.P1 | Panel mount Flow monitor | 12 – 24 VDC | 3/4 wire | Flow (Frequency) | 1*(4-20mA) 2*(S.S.R.),1*(mech. relay) | 500 |

| M9.02.W1 | Wall mount Flow monitor | 12 – 24 VDC | 3/4 wire | Flow (Frequency) | 1*(4-20mA)< 2*(S.S.R.),1*(mech. relay) | 550 |

| M9.02.W2 | Wall mount Flow monitor | 110 – 230 VAC | 3/4 wire | Flow (Frequency) | 1*(4-20mA) 2*(S.S.R.),1*(mech. relay) | 650 |

M9.02 Flow Monitor and Transmitter Field mount

| Part No. | Description/Name | Power supply | Wire power Technology | Sensor Input | Output | Lenght | Main Wetted Materials | Weight (gr.) |

|---|---|---|---|---|---|---|---|---|

| M9.02.01 | Field mount Flow monitor | 12 – 24 VDC | 3/4 wire | Flow (Frequency) | 1*(4-20mA), 2*(S.S.R.), 1*(mech. relay) | L0 | C-PVC/EPDM | 550 |

| M9.02.02 | Field mount Flow monitor | 12 – 24 VDC | 3/4 wire | Flow (Frequency) | 1*(4-20mA), 2*(S.S.R.), 1*(mech. relay) | L0 | C-PVC/FPM | 550 |

| M9.02.03 | Field mount Flow monitor | 12 – 24 VDC | 3/4 wire | Flow (Frequency) | 1*(4-20mA), 2*(S.S.R.), 1*(mech. relay) | L1 | C-PVC/EPDM | 550 |

| M9.02.04 | Field mount Flow monitor | 12 – 24 VDC | 3/4 wire | Flow (Frequency) | 1*(4-20mA), 2*(S.S.R.), 1*(mech. relay) | L1 | C-PVC /FPM | 550 |

| M9.02.05 | Field mount Flow monitor | 12 – 24 VDC | 3/4 wire | Flow (Frequency) | 1*(4-20mA), 2*(S.S.R.), 1*(mech. relay) | L0 | PVDF/EPDM | 550 |

| M9.02.06 | Field mount Flow monitor | 12 – 24 VDC | 3/4 wire | Flow (Frequency) | 1*(4-20mA), 2*(S.S.R.), 1*(mech. relay) | L0 | PVDF/FPM | 550 |

| M9.02.07 | Field mount Flow monitor | 12 – 24 VDC | 3/4 wire | Flow (Frequency) | 1*(4-20mA), 2*(S.S.R.), 1*(mech. relay) | L1 | PVDF/EPDM | 550 |

| M9.02.08 | Field mount Flow monitor | 12 – 24 VDC | 3/4 wire | Flow (Frequency) | 1*(4-20mA), 2*(S.S.R.), 1*(mech. relay) | L1 | PVDF/FPM | 550 |

| M9.02.09 | Field mount Flow monitor | 12 – 24 VDC | 3/4 wire | Flow (Frequency) | 1*(4-20mA), 2*(S.S.R.), 1*(mech. Relay) | L0 | SS316L/EPDM | 600 |

| M9.02.10 | Field mount Flow monitor | 12 – 24 VDC | 3/4 wire | Flow (Frequency) | 1*(4-20mA), 2*(S.S.R.), 1*(mech. relay) | L0 | SS316L/FPM | 600 |

| M9.02.11 | Field mount Flow monitor | 12 – 24 VDC | 3/4 wire | Flow (Frequency) | 1*(4-20mA), 2*(S.S.R.), 1*(mech. relay) | L1 | SS316L/EPDM | 600 |

| M9.02.12 | Field mount Flow monitor | 12 – 24 VDC | 3/4 wire | Flow (Frequency) | 1*(4-20mA), 2*(S.S.R.), 1*(mech. relay) | L1 | SS316L/FPM | 600 |

GET THE LATEST Flow Meter Manufacturer PRICES ON YOUR EMAIL