Injection Molding

Injection molding is the basis of modern manufacturing, offering unparalleled precision and efficiency in the production of plastic parts. The process is used in a variety of industries due to its ability to mass-produce high-quality, complex components. This highlights the intricacies of injection molding, exploring its benefits, process, applications, and the importance of custom plastic injection molding.

Custom Plastic Injection Molding Parts

Injection Molding

Injection Molding

Injection Molding

Injection Molding

Injection Molding

Injection Molding

Key Advantages of Injection Molding

High Efficiency

Injection molding is highly efficient, making it possible to mass produce parts of consistent quality. Once the initial setup is complete, the process can produce thousands of parts with minimal variation.

Precision and Accuracy

This process provides precise and accurate parts, capable of achieving tight tolerances. This accuracy is critical for applications requiring high-performance components.

Complex Geometries

Injection molding allows the creation of complex shapes and intricate details that would be challenging or impossible to achieve with other manufacturing methods.

Material Versatility

A wide range of thermoplastics can be used in injection molding, each of which has different properties such as strength, flexibility, and chemical resistance. This versatility allows the production of parts tailored to specific applications.

Reduced Waste

This process is highly efficient in terms of material use, and produces minimal waste. Excess plastic can often be recycled, contributing to more sustainable manufacturing practices.

Cost-Effectiveness

For high-volume production, injection molding is cost-effective, with lower per-unit costs than other manufacturing methods. The initial tooling investment is offset by the efficiency and scalability of the process.

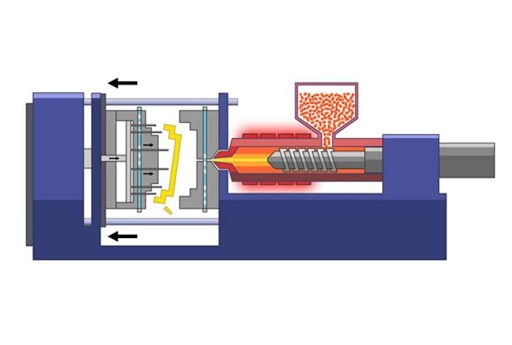

The Injection Molding Process

Design and Prototyping: The process begins with the design of the part, often using CAD software. Prototyping may be done using 3D printing or other methods to refine the design before mass production.

Mold Creation: Based on the final design a mould is made, usually made of steel or aluminium. The mould consists of two parts, which form a cavity into which the plastic is poured.

Injection Phase: The selected plastic material is melted and poured into the mold under high pressure. This ensures that the molten plastic fills every part of the cavity, and captures all the details of the design.

Cooling and Solidification: Once the mold is filled, the plastic cools and solidifies. Cooling channels inside the mold help speed up this process, ensuring uniform cooling and no defects.

Ejection: After the plastic solidifies, the mold opens, and the part is ejected. Ejector pins are usually used to push the part out of the mold without causing any damage.

Finishing: Finishing the part may require post-processing steps such as trimming, painting, or assembly. Quality control inspections ensure that each part meets the required specifications.

Applications of Injection Molding

Automotive Industry

Injection molding creates a variety of automotive components, including dashboards, bumpers, and interior panels. The ability to create durable, lightweight parts is critical to improving vehicle performance and fuel efficiency.

Medical Devices

The medical industry relies on injection molding to produce syringes, IV components, and other medical devices. Precision and biocompatibility are essential for these applications.

Consumer Goods

Everyday items such as toys, kitchen utensils, and electronic housings are manufactured using injection molding. This process can produce aesthetically pleasing and functional products.

Electronics

Injection molding produces components for electronic devices, including enclosures, connectors, and circuit board components. The ability to create complex, precise parts is critical to the functionality and reliability of electronics.

Aerospace

The aerospace industry uses injection molding to create lightweight, high-strength parts for aircraft interiors and other components. This process supports the production of parts that meet stringent safety and performance standards.

Custom Plastic Injection Molding

Custom plastic injection molding takes the standard injection molding process and tailors it to specific customer requirements. This customization can involve unique materials, specialized mold designs, or specific production techniques to meet the precise needs of the application.

Tailored Materials: Custom molding allows for the selection of specific materials that meet the unique requirements of the part, such as enhanced strength, flexibility, or resistance to chemicals and heat.

Specialized Mold Designs: Custom molds can be designed to produce parts with unique shapes, sizes, and features. This flexibility supports innovation and allows for the production of highly specialized components.

Low and High-Volume Production: Custom injection molding is suitable for both low and high-volume production runs, providing flexibility for companies with varying production needs.

Value-Added Services: Many custom injection molding services offer additional capabilities such as overmolding, insert molding, and in-mold labeling. These services enhance the functionality and aesthetics of the final product.

Quality Assurance: Custom injection molding often includes rigorous quality control processes to ensure that each part meets the highest standards. This is particularly important for industries such as medical and aerospace, where precision and reliability are critical.

What Thermoplastics are used in Injection Molding?

Standard Plastics

- PS (Polystyrene)

- PVC (Polyvinyl Chloride)

- PP (Polypropylene)

- HDPE (High Density Polyethylene)

- LDPE (Low Density Polyethylene)

- Nylon (C6H11NO)n

- Delrin (Acetal)

- UHMW (Ultra-High-Molecular-Weight Polyethylene)

Ultra High Performance Plastic

- PEEK (Polyether Ether Ketone)

- PFSA (Perfluorosulfonic Acid)

- PI (Polyimide)

- TPI (Thermoplastic Polyimide)

- PAI (Polyamide-Imide)

- HTS (High-Throughput Screening)

High Performance Plastic

- PPSU (Polyphenylsulfone)

- PEI (Polyetherimide)

- PESU (Polyethersulfone)

- PSU (Polysulfone)

- PARA (Polyarylamide)

- PPS (Polyphenylene Sulfide)

- PPA (Polyphthalamide)

- LCP (Liquid Crystal Polymer)

- HPN (Hyperform Polypropylene)

- PTFE (Teflon)

Technical Plastics

- PC (Polycarbonate)

- ABS (Acrylonitrile Butadiene Styrene)

- MABS (Methacrylate Acrylonitrile Butadiene Styrene)

- ASA (Acrylonitrile Styrene Acrylate)

- PMMA (Polymethyl Methacrylate)

- PVC (Polyvinyl Chloride)

- PBT (Polybutylene Terephthalate)

- PET (Polyethylene Terephthalate)

- POM (Polyoxymethylene)

- PA 6 (Polyamide)

- PA 6.6/PPE (Polyamide/ Polyphenylene Ether)

- PA 12 (Polyamide)

- TPE (Thermoplastic Elastomer)

- TPU (Thermoplastic Polyurethane)

How to Reduce Injection Molding Costs?

Injection molding can be a cost-effective manufacturing process, but certain strategies can help further reduce costs, especially when producing high volumes.

Here are some key ways to reduce injection molding costs:

1. Optimize Part Design

Design parts with simpler geometries to reduce mold complexity. Avoid undercuts, sharp corners, and intricate details that require more expensive molds or secondary processes.

2. Choose the Right Material

Choose the most cost-effective material that meets the performance requirements. Some high-performance plastics may not be necessary for every application, so opting for a more economical material can save money.

Recycled Materials: Consider using recycled materials when possible. These materials are often less expensive than virgin resins and can provide acceptable performance in certain applications.

3. Optimize Mold Design

Design molds with fewer moving parts and simpler mechanisms, which can reduce mold manufacturing costs. For instance, a mold that avoids side actions or multiple slides will generally cost less to produce.

4. Optimize Production Efficiency

Reducing cycle time by optimizing cooling and processing conditions can increase production speed and lower overall costs. Faster cycle times mean more machined parts are produced in less time, reducing labor and machine costs.

5. Reduce Setup Costs

Group similar parts or use the same material in one production run to reduce the number of mold changes and machine setup times.

6. Work with an Experienced Manufacturer

Partner with an experienced injection molding supplier who can offer design for manufacturability (DFM) support. Early collaboration can help identify cost-saving opportunities during the design and prototyping stages.

7. Use Hot Runner Systems

Hot runner systems keep the plastic in the runner channels molten, reducing material waste and eliminating the need to trim excess material. While these systems are more expensive upfront, they can reduce material costs over time by reducing scrap rates.

8. Focus on Quality Control

Ensure that part designs, material selections, and mold construction are optimized to minimize defects. High reject rates and rework can significantly increase costs, so investing in quality control can save money in the long run.

9. Consider Alternative

Manufacturing Processes

For low-volume production, consider alternative manufacturing methods like 3D printing or urethane casting. These processes often have lower upfront tooling costs, making them more cost-effective for small runs.

10. Optimize Order Volume

• Bulk Ordering: Ordering in larger quantities often reduces the per-unit cost due to economies of scale. Larger orders can help justify the cost of multi-cavity molds, automated systems, and other production efficiencies.

• Long-Term Contracts: Establish long-term contracts with injection molding suppliers to secure better pricing over time, reduce setup costs, and ensure a steady production flow.

Injection Molding Components OR Parts Manufactured by Petron Thermoplast

1. Automotive Components

- Dashboard panels

- Door handles and trims

- Airflow ducts

- Grilles and vents

- Engine covers

- Gear shifter components

- Interior and exterior trim parts

2. Electrical and Electronics Components

- Electrical connectors and sockets

- Switch housings

- Cable management components

- Enclosures for electronics

- Sensor housings

- Wire guides and retainers

3. Medical and Healthcare Parts

- Medical device casings

- Syringe components

- Tubing connectors

- Surgical instrument housings

- Diagnostic device parts

- Wearable medical device components

4. Packaging Products

- Caps and closures

- Food and beverage container lids

- Pharmaceutical packaging components

- Custom packaging inserts

- Bottle tops and spouts

5. Consumer Goods

- Kitchen utensils and tools

- Plastic containers and lids

- Toy components

- Household appliance housings

- Grips and handles for products

6. Industrial and Mechanical Parts

- Gears, sprockets, and pulleys

- Bearings and bushings

- Seals, gaskets, and O-rings

- Valves and pump components

- Industrial housings and enclosures

7. Aerospace Components

- Interior panel components

- Fasteners and clips

- Structural support brackets

- Instrument panels and covers

8. Agricultural Equipment Parts

- Irrigation system components

- Nozzles and sprayers

- Tractor and machinery parts

- Feed and fertilizer distribution parts

9. Home Appliance Parts

- Vacuum cleaner components

- Refrigerator drawers and liners

- Washing machine parts

- Microwave and oven components

- Air conditioner housings

10. Custom Molded Parts

- Custom-engineered parts based on specific client requirements

- Multi-material and overmolded parts

- Prototyping and small production runs

Types of Injection Molding

Injection molding is a versatile manufacturing process used to produce a wide range of plastic parts and components. Different types of injection molding processes have been developed to meet specific production needs, each with its own unique characteristics and applications. Here are the most common types of injection molding:

1. Standard Injection Molding

Involves melting thermoplastic resin and injecting it into a mold cavity where it cools and solidifies into the final shape.

2. Over Molding

Combines two or more materials in a single part by molding one material over another. The first material (the substrate) is molded, and then a second material is injected over it.

3. Insert Molding

Involves placing a pre-formed insert (metal or another component) into the mold before injecting the plastic. The plastic flows around the insert, bonding it into the part.

4. Gas-Assisted Injection Molding

Gas (usually nitrogen) is injected into the molten plastic inside the mold, creating hollow sections within the part.

5. Thin-Wall Injection Molding

Designed for producing parts with very thin walls, requiring higher pressures and faster cycle times to fill the mold properly.

6. Micro Injection Molding

Specialized injection molding technique used to produce very small and precise parts, often with micron-level tolerances.

7. Liquid Silicone Rubber (LSR) Injection Molding

Involves injecting liquid silicone rubber into a heated mold where it cures into a flexible elastomer.

8. Two-Shot (Multi-Shot) Injection Molding

Involves injecting two different materials or colors into the same mold in two or more stages to produce a multi-material or multi-color part.

9. Structural Foam Molding

A small amount of chemical blowing agent or gas is added to the plastic before injection, creating a foamed core with a solid outer skin.

10. Reaction Injection Molding (RIM)

Involves mixing two liquid components (typically a polyol and an isocyanate) that chemically react to form a solid part as they cure in the mold.

11. Cube Molding

A rotating cube mold is used, where each side of the cube corresponds to a different molding stage, allowing multiple processes to occur simultaneously.

Limitations of Injection Molding

While injection molding is a highly efficient and widely used manufacturing process, it has certain limitations that may affect its suitability for specific applications. Below are some of the primary limitations of injection molding:

• High Initial Tooling Costs

• Design Constraints

• Material Limitations

• Part Size Restrictions

• Production Volume

• Post-Processing Requirements

• Cycle Time for Complex Parts

• Material-Specific Challenges

• Environmental Impact

Technological Advancements in Injection Molding

Advanced Materials

The development of new thermoplastic materials has expanded the capabilities of injection molding, allowing for the production of parts with enhanced properties such as higher strength, better chemical resistance, and improved thermal stability.

Process Automation

Automation technologies, including robotic systems, have improved the efficiency and consistency of injection molding. Automated systems can handle repetitive tasks, reducing labor costs and increasing production speeds.

Simulation Software

Mold flow simulation software helps optimize the injection molding process by predicting how the molten plastic will flow within the mold. This technology reduces trial-and-error, improves part quality, and shortens development times.

Additive Manufacturing

Integrating 3D printing with injection molding allows for rapid prototyping and the creation of complex molds. Additive manufacturing supports the production of low-volume, custom parts with intricate designs.

Sustainable Practices

Innovations in recycling and material conservation are making injection molding more sustainable. Biodegradable plastics and the recycling of scrap material contribute to reducing the environmental impact of the manufacturing process.

Injection molding is a versatile and efficient manufacturing process that plays a vital role in producing high-quality plastic parts for a wide range of industries. Its ability to create precise, durable and complex components has made it indispensable in sectors such as automotive, medical, electronics and consumer goods.

Custom plastic injection molding further enhances the capabilities of this process, providing tailored solutions that meet specific customer requirements. By taking advantage of advanced materials, automation, and cutting-edge technologies, manufacturers can achieve greater precision, efficiency, and consistency in their production processes.

Understanding the intricacies of injection molding and its potential for customization helps companies innovate and maintain a competitive edge in the market. Whether for mass production or specialized applications, injection molding drives progress and excellence in modern manufacturing.

Conclusion

Injection molding remains one of the most versatile and reliable manufacturing processes for producing high-quality, complex plastic components at scale. By Choosing Petron Thermoplast, you can trust that your products will be manufactured with the utmost care, ensuring both performance and durability. Our expertise in working with a wide range of thermoplastics, coupled with our innovative molding technologies, makes us a partner you can depend on for all your injection molding requirements.