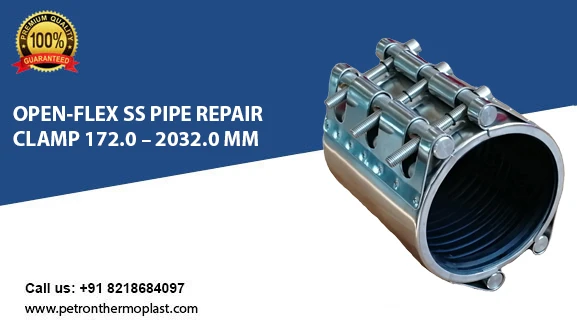

Open-Flex SS Pipe Repair Clamp 172.0 – 2032.0 mm

A leaky water or gas pipe can cause significant difficulties, so it should be repaired as soon as possible but in a safe and long-lasting manner to prevent additional water or gas loss. Our stainless steel pipe fixing clamp can be used to fix broken or damaged pipelines permanently.

Pipe leak clamp is a type of device used to repair and seal a leaky pipeline. This is a long-term mending method. This procedure can be used to repair locally corrupted, damaged, and cracked pipes. Pipeline clamps are designed and manufactured by our organization. Our pipeline clamps may be customized to fit a variety of dimensions and pressure ratings. Tie-in, hot tapping, repair, leak sealing, and reinforcing are just a few of the uses. In our high-tech machine shop, we precisely machine our pipe repair clamps.

The transportation and transfer of fluids from wellheads to offshore process system pipework and pipelines to refining facilities are critical to the oil and gas industry’s safety, efficiency, and economic sustainability.

Pipe Repair Clamps

Pipe Repair Clamps

We have a wide range of superior quality Pipe Repair Clamps Manufacturer in India. We have all thermoplastic piping materials and working successfully for over 60 years.

What is the purpose of the pipe repair clamps?

The high pressure pipe repair clamps are essentially a pre-rolled stainless steel plate with a rubber lining secured with welded bolts and nuts. The clamp fasteners’ tensile strain is translated to radial pressure on the rubber liner, ensuring a secure seal.

Key Features

• Lightweight strap clamp for repair or intervention in a specific area

• Self-energised pipe-to-pipe sealing

• Installation is quick and straightforward.

• The low-profile design enables installation in tight spaces.

• Repair (Blind), Hot Tap (Flanged), or Encapsulation (Capped) seal housings are available.

• Low and high-pressure applications are both possible.

• Their design allows components to be reused for different pipe geometries.

• Sealing material is provided according to the application (NBR, HNBR, Viton, HPU)

• Carbon steel that complies with NACE standards is standard; alternative materials are available upon request.

• Single or multiple seal configurations are available.

OPEN-FLEX 1 GT SS PIPE REPAIR CLAMP – 73.0 – 168.3 MM | Technical Details

| Components / Materials | W1 | W2 | W4 | W5 |

|---|---|---|---|---|

| Casing | S355MC hot-dip galvanised | AISI 316 L or similar | AISI 316 L or similar | |

| Bolts | AISI 4135 | AISI 4135 | A4 – 80 | |

| Bars | AISI 12L14 galvanised | AISI 12L14 galvanised | AISI 316 L or similar | |

| Strip insert (option) | AISI 316 L or similar / HDPE | AISI 316 L or similar / HDPE | AISI 316 L or similar / HDPE |

| Sealing sleeve | Temp.: | -20°C up to +100°C |

| EPDM | Medium: | all qualities of water waste water air solids and chemical products |

| Sealing sleeve | Temp.: | -20°C up to +80°C |

| NBR | Medium: | water gas oil fuel and other hydrocarbons |

| Sealing sleeve | Temp.: | -20°C up to +180°C |

| FPM/FKM | Medium: | ozone oxygen acids gas oil and fuel (only with strip insert) |

| OD[mm] | Clamping rang[mm] |

PN |

PN | |||||

| 219.1 | 216 – 222 | 2.5 | 6 | 10 | 16 | 20 | 25 | [bar] |

| 172.0 | 170 – 174 | |||||||

| 180.0 | 178 – 182 | |||||||

| 200.0 | 198 – 202 | |||||||

| 219.1 | 217 – 222 | |||||||

| 250.0 | 248 – 253 | |||||||

| 267.0 | 264 – 270 | |||||||

| 273.0 | 270 – 276 | |||||||

| 304.0 | 301 – 307 | |||||||

| 323.9 | 321 – 327 | |||||||

| 355.6 | 353 – 358 | |||||||

| 406.4 | 404 – 409 | |||||||

| 457.2 | 454 – 460 | |||||||

| 508.0 | 505 – 511 | |||||||

| 558.8 | 556 – 562 | |||||||

| 609.6 | 606 – 613 | |||||||

| 711.2 | 708 – 715 | |||||||

| 762.0 | 758 – 766 | |||||||

| 812.8 | 809 – 817 | |||||||

| 914.4 | 910 – 918 | |||||||

| 1016.0 | 1012 – 1020 | |||||||

| 1117.6 | 1114 – 1122 | |||||||

| 1219.2 | 1215 – 1224 | |||||||

| 1320.8 | 1316 – 1325 | |||||||

| 1422.4 | 1418 – 1427 | |||||||

| 1524.0 | 1519 – 1529 | |||||||

| 1600.0 | 1595 – 1605 | |||||||

| 1625.6 | 1621 – 1631 | |||||||

| 1727.2 | 1722 – 1732 | |||||||

| 1828.8 | 1824 – 1834 | |||||||

| 1930.4 | 1925 – 1935 | |||||||

| 2032.0 | 2027 – 2037 | |||||||

Remarks:

- PN ( ) = working pressure considering the application loads

- Test pressure = PN ( ) x 1.5 (for example industry, water supply etc.)

- PN ( ) = nominal pressure, includes four times safety factor

- (e.g. shipbuilding)

- Strip inserts are optional accessories (see page 87)

- Additional sealing sleeves, pressure and temperature ranges on reques

Versions:

GET THE LATEST OPEN-FLEX SS PIPE REPAIR CLAMP 172.0 – 2032.0 MM PRICES ON YOUR EMAIL