PVDF Y Strainer / Sediment Strainer

As a Safety Filter, PVDF Y Strainer known as PVDF Sediment Strainers. These are meant to capture any solid contaminants that may sometimes be in the line. Solenoid valves and other devices with small holes, such as pumps or control valves, are protected by this. The filter screen is easily replaceable and is available in a variety of meshes.

The pump and meter are protected by a PVDF sediment strainer, which removes suspended particles and contaminants. The position of the screen can be easily determined due to its transparent thermoplastic structure. Optional in-line cleaning valve flushes collected particles from strainer port

Because of its True Union design, it is easy to install or repair without enlarging the pipeline. A great filtering capacity and minimum pressure drop are two of its key features. As a result of the transparent PVDF sediment strainer, the condition of the filter screen can be easily assessed. Everything about it is a thermoplastic products.

PVDF Valves

PVDF Valves

Get Quick Information

The RV Sediment strainer limits the passage of any solid particles present in the fluid by means of a strainer.

• Connection system for solvent weld, threaded and flanged joints

• Strainer mounted on an easily removed support that facilitates the cleaning or replacement

•Valve material compatibility (PVC-U) with water conveyance, drinking water and other food substances according to current regulations

• Can be maintained with the valve body installed

| Technical specifications | |

|---|---|

| Construction | Sediment strainer |

| Size range | DN 15 ÷ 50 |

| Nominal pressure | PVC-U Grey DN 10÷50: PN 16 with water at 20 °C DN 65: PN 10 with water at 20 °C DN 80÷100: PN 6 with water at 20 °C PVC-U Transparent DN 10÷25: PN 16 with water at 20 °C DN 32÷50: PN 10 with water at 20 °C DN 65: PN 6 with water at 20 °C DN 80÷100: PN 4 with water at 20 °C |

| Temperature range | 0 °C ÷ 60 °C |

| Coupling standards | Solvent welding: EN ISO 1452, EN ISO 15493, BS 43461, DIN 8063, NF T54-028, ASTM D 2467, JIS K 6743. Can be coupled to pipes according to EN ISO 1452, EN ISO 15493, DIN 8062, NF T54-016, ASTM D 1785, JIS K 6741 Thread: UNI ISO 228-1, DIN 2999, ASTM D 2467, JIS B 0203 Flanging system: ISO 7005-1, EN ISO 1452, EN ISO 15493, EN 558-1 (DN 10÷50), DIN 2501, ANSI B.16.5 cl.150, JIS B 2220 |

| Reference standards | Construction criteria: EN ISO 1452, EN ISO 15493 Test methods and requirements: ISO 9393 Installation criteria: DVS 2204, DVS 2221, UNI 11242 |

| Valve material | Body: PVC-U grey or trasparent Strainer: PVC-U or STAINLESS steel |

| Seal material | EPDM, FKM |

Sediment Strainer

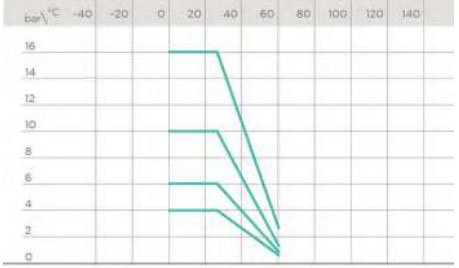

PRESSURE VARIATION ACCORDING TO TEMPERATURE

For water and non-hazardous fluids with regard to which the material is classified as CHEMICALLY RESIS-TANT. In other cases, a reduction of the nominal pressure PN is required(25 years with safety factor).

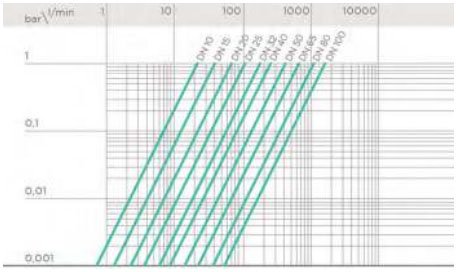

PRESSURE DROP GRAPH

STRAINER DIMENSION

| Pitch (mm) | 0,7 | 1,0 | 1,5 | 2,0 | 2,5 |

|---|---|---|---|---|---|

| number of holes per cm2 | 260 | 125 | 67 | 36 | 26 |

| ASTM series equivalent in strainer | 45 | 70 | 40 | 35 | 30 |

| ø equivalent hole μm | 370 | 200 | 420 | 550 | 580 |

| strainer material | STAINLESS STEEL | PVC-U | PVC-U | PVC-U | PVC-U |

TOTAL STRAINER AREA ATOT (CM2)

| DN | 10 | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 |

|---|---|---|---|---|---|---|---|---|---|---|

| Atot | 16 | 16 | 23,5 | 36 | 53 | 69 | 101 | 197 | 247 | 396 |

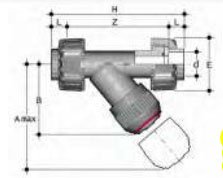

RVUIV-RVUIT

RVUIV PVC-U rigid – RVUIT PVC-U transparent

Sediment strainer with female union ends for solvent welding

| d | DN | PN RVUIV | PN RVUIT | A max | B | E | H | L | Z | Fig. | g | RVUIV EPDM code | RVUIT EPDM code |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 16 | 10 | 16 | 16 | 125 | 72 | 55 | 135 | 14 | 107 | A | 203 | RVUIV016E | RVUIT016E |

| 20 | 15 | 16 | 16 | 125 | 72 | 55 | 135 | 16 | 103 | A | 211 | RVUIV020E | RVUIT020E |

| 25 | 20 | 16 | 16 | 145 | 84 | 66 | 158 | 19 | 120 | A | 358 | RVUIV025E | RVUIT025E |

| 32 | 25 | 16 | 16 | 165 | 95 | 75 | 176 | 22 | 132 | A | 526 | RVUIV032E | RVUIT032E |

| 40 | 32 | 16 | 10 | 190 | 111 | 87 | 207 | 26 | 155 | A | 733 | RVUIV040E | RVUIT040E |

| 50 | 40 | 16 | 10 | 210 | 120 | 100 | 243 | 31 | 181 | A | 1095 | RVUIV050E | RVUIT050E |

| 63 | 50 | 16 | 10 | 240 | 139 | 120 | 298 | 38 | 222 | A | 1843 | RVUIV063E | RVUIT063E |

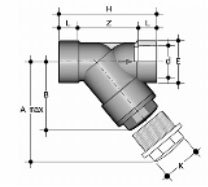

RVIV-RVIT

RVIV PVC-U rigid – RVIT PVC-U transparent

Sediment strainer with female ends for solvent welding

| d | DN | PNRVIV | PNRVIT | Amax | B | E | H | K | L | Z | Fig. | g | RVIV EPDM code | RVIT EPDM code |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 75 | 65 | 10 | 6 | 300 | 179 | 104 | 243 | 96 | 33 | 155 | B | 2385 | RVIV075E | RVIT075E |

| 90 | 80 | 6 | 4 | 325 | 192 | 116 | 262 | 105 | 37 | 160 | B | 2975 | RVIV090E | RVIT090E |

| 110 | 100 | 6 | 4 | 385 | 231 | 138 | 325 | – | 61 | 203 | C | 4610 | RVIV110E | RVIT110E |

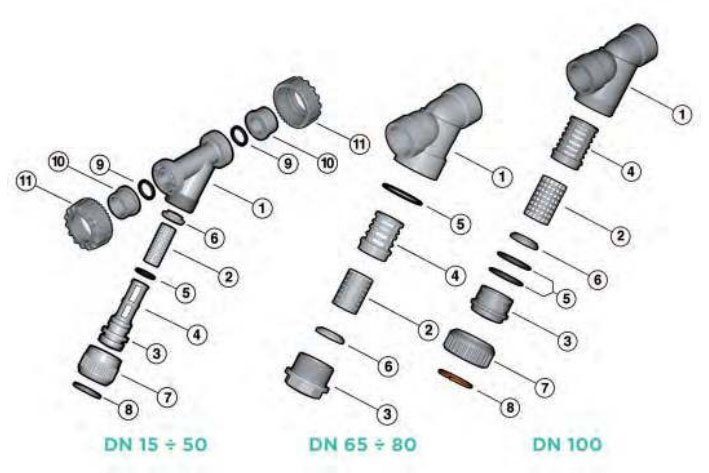

EXPLODED VIEW

- 1 Body (PVC-U – 1)

- 2 Strainer (PVC-U/STAINLESSsteel – 1)*

- 3 Bonnet (PVC-U – 1)

- 4 Strainer support (PVC-U – 1)

- 5 O-Ring (EPDM-FKM – 1)*

- A-B

- 5 C O-Ring (EPDM-FKM – 2)*

- 6 Washer (PVC-U – 1)

- 7 Union nut (PVC-U – 1)

- 8 Retaining ring (PVC-U – 1)

- 9 Socket seal O-Ring (EPDM-FKM- 2)*

- 10 End connector (PVC-U – 2)*

- 11 Union nut (PVC-U – 2)

The material of the component and the quantity supplied are indicated between brackets

GET THE LATEST PVDF Sediment Strainer PRICES ON YOUR EMAIL