UPVC Angle Seat Valve

UPVC Angle Seat Valve Supplier in India, that are activated backwards can prevent fluid pressure. It is suitable for high-flow work and is installed in lines where the conventional ball and other irrigation valves are difficult to assemble and use.

This is a pneumatically-operated, piston-actuated valve with a piston actuator that acts linearly to pull a seal out of its seat. Unseated, the seat is placed at an angle to allow for maximal circulation. Hot temperatures and big flow rates, such as steam or water; make angle seat piston valve a good choice.

Installed horizontally or vertically, it’s flexible. When utilized in an underground valve box, such known as well UPVC Ball Valve is exceedingly simple to access and wash after a time of use. Easy operation of UPVC Angle Seat Valve manufacturer & exporter in India.

PVC Angle Seat Piston Valve is made possible by a smooth throttling wheel. A fully closed valve will have zero leaking within the operating pressure limit. Design-wise, it’s robust and durable. There is no water hammering when it is turned on.

UPVC Valves Range

UPVC Valves Manufacturers in India. We provide different types of Valve Suppliers like- PVC Ball Valve, Ball Valve and Industrial Valves etc. If you want to buy now, click our website.

UPVC Valves Range

UPVC Angle Seat Valve Technical Information

The VV angle seat valve is a shutting-off and regulating valve particularly suitable for clean fluids.

• Connection system for solvent weld, threaded and flanged joints

• Can be installed in any position

• No metal parts in contact with the fluid

• Valve material compatibility (PVC-U) with water, drinking water and other

food substance conveyance according to current regulations

• Can be maintained with the valve body installed

| Technical specifications | |

|---|---|

| Construction | Angle seat shutting-off and regulating valve |

| Size range | DN 10 ÷ 50 |

| Nominal pressure | DN 10÷25: PN 16 with water at 20 °C DN 32÷50: PN 10 with water at 20 °C |

| Temperature range | 0 °C ÷ 60 °C |

| Coupling standards | Solvent welding: EN ISO 1452, EN ISO 15493, BS 4346-1, DIN 8063, NF T54-028, ASTM D 2467, JIS K 6743. Can be coupled to pipes according to EN ISO 1452, EN ISO 15493, DIN 8062, NF T54-016, ASTM D 1785, JIS K 6741. Thread: ISO 228-1, DIN 2999, ASTM D 2467, JIS B 0203. Flanging system: ISO 7005-1, EN ISO 1452, EN ISO 15493, EN 558-1 (DN 10÷50) , DIN 2501, ANSI B.16.5 cl. 150, JIS B 2220. |

| Reference standards | Construction criteria: EN ISO 1452, EN ISO 15493 Test methods and requirements: ISO 9393 Installation criteria: DVS 2204, DVS 2221, UNI 11242 |

| Valve material | PVC-U |

| Seal material | EPDM+PE (EPDM+PTFE or FKM+PTFE on request) |

| Control options | Manual control |

ANGLE SEAT VALVE

PRESSURE VARIATION ACCORDING TO TEMPERATURE

For water and non-hazardous fluids with regard to which the material is classified as CHEMICALLY RESIS-TANT. In other cases, a reduction of the nominal pressure PN is required(25 years with safety factor).

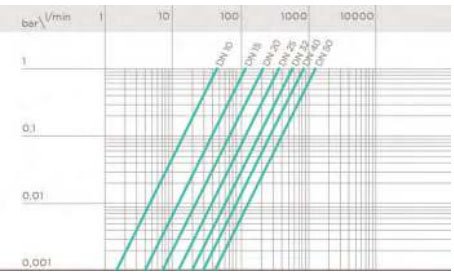

PRESSURE DROP GRAPH

KV 100 FLOW COEFFICIENT

| DN | 10 | 15 | 20 | 25 | 32 | 40 | 50 |

|---|---|---|---|---|---|---|---|

| Kv100 l/min | 47 | 110 | 205 | 375 | 560 | 835 | 1300 |

The Kv 100 flow coefficient is the Q flow rate of litres per minute of water at a temperature of 20°C that will generate Δp= 1 bar pressure drop at a certain valve position. The Kv100 values shown in the table are calculated with the valve completely

open.

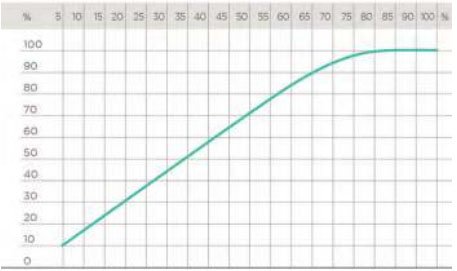

RELATIVE FLOW COEFFICIENT GRAPH

The relative flow coefficient is the flow rate through the valve as a function of the degree of valve opening. Horizontal axis: Percentage opening of the valve Vertical axis: Relative flow coeffi- cient

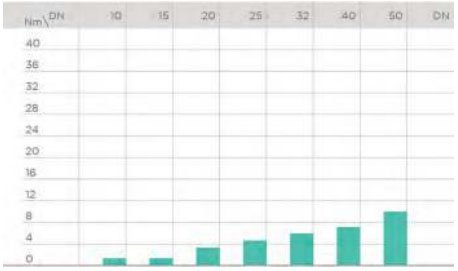

OPERATING TORQUE AT MAXIMUM WORKING PRESSURE

VVUIV

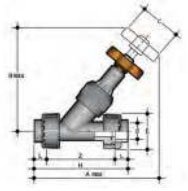

Angle seat valve with female union ends for solvent welding, metric series| d | DN | PN | Amax | Bmax | C | E | H | L | Z | g | EPDM+PEcode |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 16 | 10 | 16 | 170 | 124 | 60 | 55 | 135 | 14 | 107 | 238 | VVUIV016E |

| 20 | 15 | 16 | 173 | 124 | 60 | 55 | 135 | 16 | 103 | 251 | VVUIV020E |

| 25 | 20 | 16 | 197 | 146 | 60 | 66 | 158 | 19 | 120 | 413 | VVUIV025E |

| 32 | 25 | 16 | 223 | 173 | 70 | 75 | 176 | 22 | 132 | 621 | VVUIV032E |

| 40 | 32 | 16 | 258 | 195 | 85 | 87 | 207 | 26 | 155 | 903 | VVUIV040E |

| 50 | 40 | 16 | 295 | 222 | 105 | 100 | 243 | 31 | 181 | 1320 | VVUIV050E |

| 63 | 50 | 16 | 359 | 269 | 130 | 120 | 298 | 38 | 222 | 2238 | VVUIV063E |

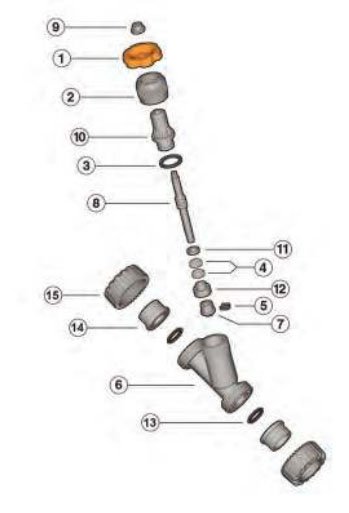

EXPLODED VIEW

- 1 Handwheel (PVC-U – 1)

- 2 Union nut (PVC-U – 1)

- 3 O-Ring (EPDM-FKM – 1)*

- 4 Gland Packing (PE-PTFE – 2)*

- 5 Locking clip (PVC-U – 1)

- 6 Body (PVC-U – 1)

- 7 Shutter (PVC-U – 1)

- 8 Stem (PVC-U – 1)

- 9 Nut (PVC-U – 1)

- 10 Bonnet (PVC-U – 1)

- 11 Bottom sleeve (PVC-U – 1)

- 12 Gland (PVC-U – 1)

- 13 Socket seal O-Ring (EPDM-FKM- 2)

- 14 End connector (PVC-U – 2)

- 15 Union nut (PVC-U – 2)

* Spare parts

The material of the component and the quantity supplied are indicated between brackets

GET THE LATEST UPVC Angle Seat Valve PRICES ON YOUR EMAIL