UPVC Air Release Valve

In pressured pipe systems, an automated air release valve is essential. UPVC Air Release Valve Manufacturer & Suppliers in India.

Air confined in a pipe will gradually climb to the top and accumulate at the system’s highest points. Pump breakdowns, incorrect instrumentation measurements, deterioration, flow problems, and water pounding or pressure spikes can all be caused by trapped PVC pressure relief valve. Unwanted air in the tube also makes the pump working more difficult, which uses more power.

The purpose of an UPVC Air Release Valve, also known as an Air Relief Valve, is to relieve trapped air that gathers at each maximum height of a full-pressured tube. Because the inner lever system amplifies the floating force to be higher than the inner pressure, a PVC air release valve may open against inner pressure.

When gas bubbles form in the air relief valve, the larger force opens the opening. PVC Air Release Valve is the mainly used for pipeline productivity and safety against water pounding.

UPVC Valves Range

UPVC Valves Manufacturers in India. We provide different types of Valve Suppliers like- PVC Ball Valve, Ball Valve and Industrial Valves etc. If you want to buy now, click our website.

UPVC Valves Range

UPVC Air Release Valve Technical Information

The purpose of the VA air release is to eliminate any air entering the pipe with the liquid.

• Connection system for solvent weld and threaded joints

• No metal parts in contact with the fluid

• Can be used as a vacuum breaker valve when installed with the nut at the

bottom

• Valve material compatibility (PVC-U) with water, drinking water and other

food substance conveyance according to current regulations

• Can be maintained with the valve body installed

| Technical specifications | |

|---|---|

| Construction | Air release valve |

| Size range | DN 15 ÷ 50 |

| Nominal pressure | PN 16 with water at 20 °C |

| Temperature range | 0 °C ÷ 60 °C |

| Coupling standards | Solvent welding: EN ISO 1452, EN ISO 15493, BS 4346-1, DIN 8063, NF T54-028. Can be coupled to pipes according to EN ISO 1452, EN ISO 15493, DIN 8062, NF T54-016. Thread: ISO 228-1, DIN 2999. |

| Reference standards | Construction criteria: EN ISO 16137 EN ISO 1452, EN ISO 15493 Test methods and requirements: ISO 9393 Installation criteria: DVS 2204, DVS 2221, UNI 11242 |

| Valve material | PVC-U |

| Seal material | EPDM |

PVC AIR RELEASE VALVE INFORMATION

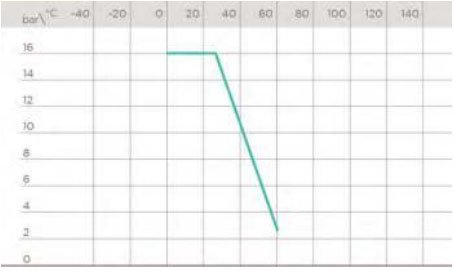

PRESSURE VARIATION ACCORDING TO TEMPERATURE

For water and non-hazardous fluids with regard to which the material is classified as CHEMICALLY RESIS-TANT. In other cases, a reduction of the nominal pressure PN is required(25 years with safety factor).

VAIV

Air release valve with male ends for solvent welding, metric series

| d | DN | PN | E | H | L | L1 | Z | g | Code |

|---|---|---|---|---|---|---|---|---|---|

| 20 | 15 | 16 | 55 | 103 | 16 | 18 | 87 | 105 | VAIV020E |

| 25 | 20 | 16 | 66 | 125 | 19 | 20 | 106 | 185 | VAIV025E |

| 32 | 25 | 16 | 75 | 150 | 22 | 24 | 128 | 280 | VAIV032E |

| 40 | 32 | 16 | 87 | 171 | 26 | 28 | 145 | 415 | VAIV040E |

| 50 | 40 | 16 | 100 | 187 | 31 | 34 | 156 | 570 | VAIV050E |

| 63 | 50 | 16 | 122 | 223 | 38 | 41 | 185 | 950 | VAIV063E |

VAFV

Air release valve with BSP threaded female ends

| R | DN | PN | E | H | L | Z | g | Code |

|---|---|---|---|---|---|---|---|---|

| 1/2” | 15 | 16 | 55 | 124 | 15 | 94 | 120 | VAFV012E |

| 3/4” | 20 | 16 | 66 | 149 | 16,3 | 116,4 | 205 | VAFV034E |

| 1” | 25 | 16 | 75 | 175 | 19,1 | 136,8 | 360 | VAFV100E |

| 1” 1/4 | 32 | 16 | 87 | 200 | 21,4 | 157,2 | 475 | VAFV114E |

| 1” 1/2 | 40 | 16 | 100 | 209 | 21,4 | 166,2 | 670 | VAFV112E |

| 2” | 50 | 16 | 122 | 248 | 25,7 | 196,6 | 1130 | VAFV200E |

EXPLODED VIEW

- 1 Body (PVC-U – 1)

- 2 Piston (PVC-U – 1)

- 3 End connector (PVC-U – 1)

- 4 Union nut (PVC-U – 1)

- 5 O-Ring (EPDM – 1)*

- 6 Piston gasket (EPDM – 1)*

The material of the component and the quantity supplied are indicated between brackets

GET THE LATEST UPVC Air Release Valve PRICES ON YOUR EMAIL